Zinc Alloy Centralizer

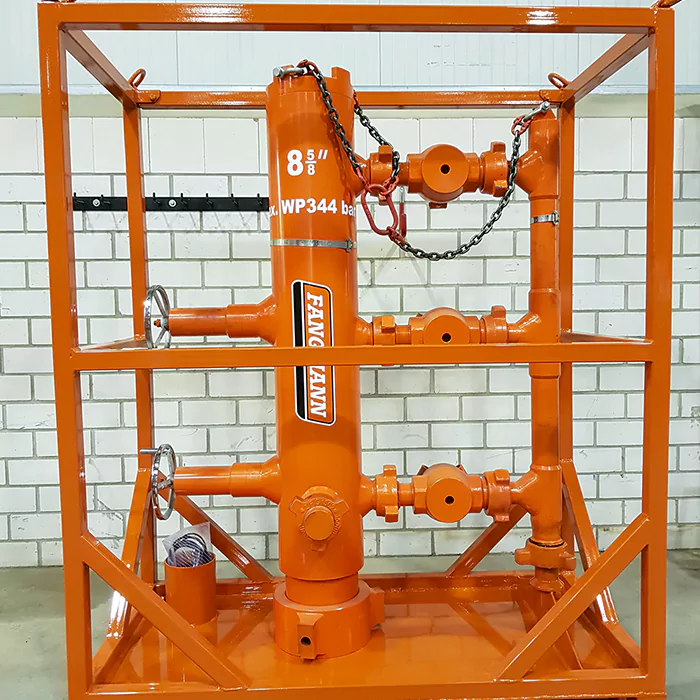

A Zinc Alloy Centralizer is a solid body casing centralizer manufactured using a casting process. It is made from high-strength, wear-resistant zinc alloy and is typically designed as a one-piece structure with spiral blades or straight blades. Puyang Zhongshi Group is the leading API certified factory and supplier for all types of casing centralizers including Zinc Alloy Casing Centralizer. Contact us consult for free!

What is a Composite Centralizer?

A Zinc Alloy Centralizer is a solid body casing centralizer manufactured using a casting process. It is made from high-strength, wear-resistant zinc alloy and is typically designed as a one-piece structure with spiral blades or straight blades.

This type of centralizer is used to provide positive standoff, ensuring the casing remains concentric within the wellbore.

Key Advantages of Composite Centralizer

Low Coefficient of Friction: Zinc alloy has a relatively low friction coefficient, which significantly reduces torque and drag while running casing. This is especially crucial for highly deviated and horizontal wells, helping the casing reach total depth successfully.

High Strength and Wear Resistance: The zinc alloy casting offers excellent strength to withstand high side loads without the blades bending or fracturing in complex wellbores.

Maximum Flow-by: Compared to steel solid body centralizers, zinc alloy allows for thinner blade walls while maintaining strength. This maximizes the annular flow area, improving cement slurry bypass efficiency.

High Temperature and Pressure Resistance (HTHP): Many zinc alloy centralizers are capable of operating reliably in high-temperature environments, often exceeding $400^\circ\text{F}$ (approx. $204^\circ\text{C}$).

Turbulence/Swirl Effect: The spiral blade design can induce turbulence in the cement slurry, which helps to better remove mud cake from the wellbore wall, enhancing mud displacement efficiency and improving cement bonding quality.

Millable Construction: Zinc alloy is a material that can be rapidly milled or drilled out by a drill bit, making it safe to place these centralizers across sections intended for subsequent operations like casing exits or sidetracking.

Zinc Aolly Centralizer is suitable for

Due to their low friction and high strength, zinc alloy centralizers are particularly suited for the following drilling environments:

- Highly Deviated and Horizontal Wells: This is the primary application. The low-friction nature of the zinc alloy is critical for ensuring successful casing run-in against high drag forces.

- Extended Reach Drilling (ERD): Used for ultra-long horizontal sections where tools must maintain extremely low drag performance.

- Casing Rotation During Cementing: The low friction coefficient allows the centralizer to act effectively as a bearing during casing rotation, reducing overall torque.

- Critical Cementing Zones: The spiral blades’ turbulence effect helps achieve a more uniform and robust cement seal in crucial formation zones.

Get Quotation

Zinc Alloy Centralizer

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

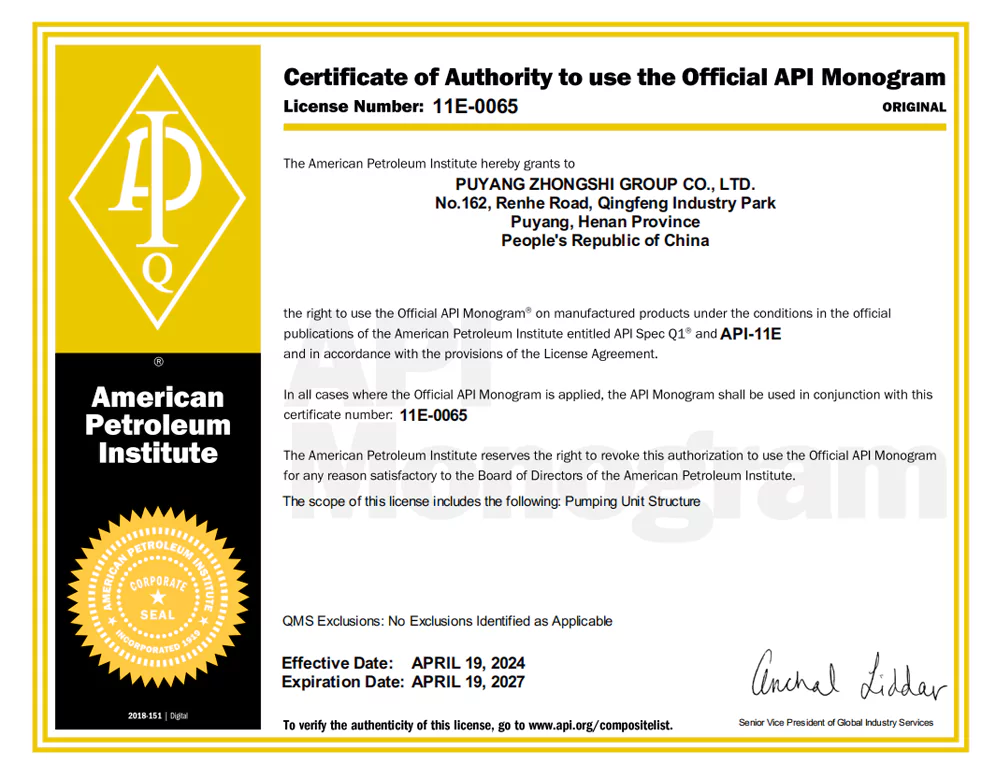

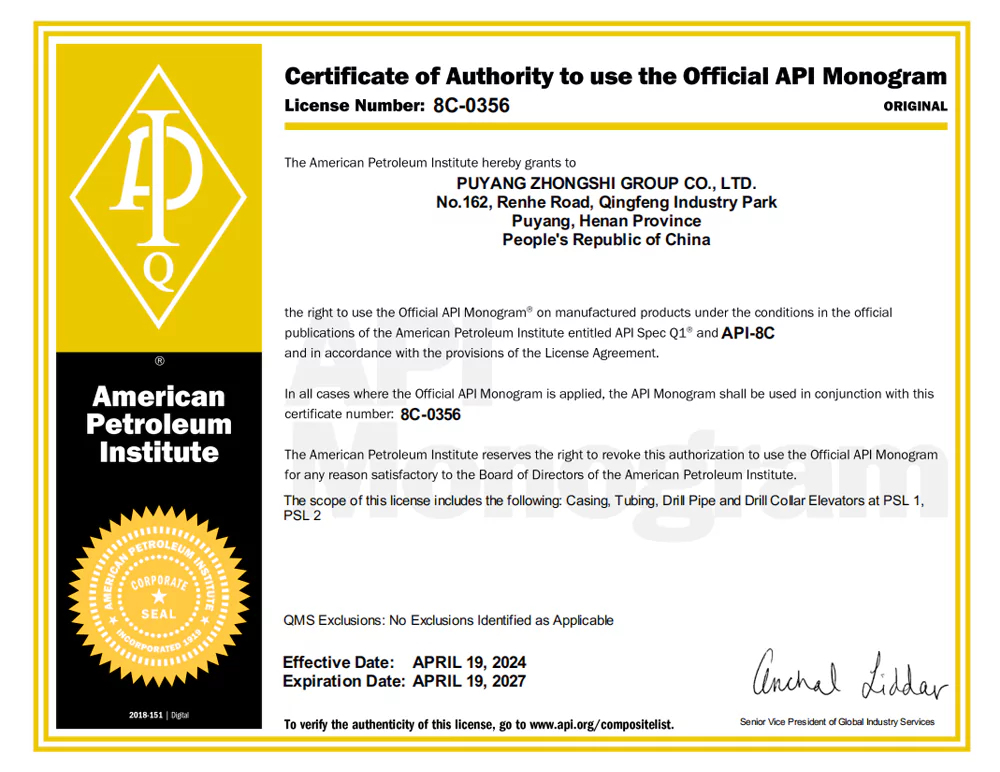

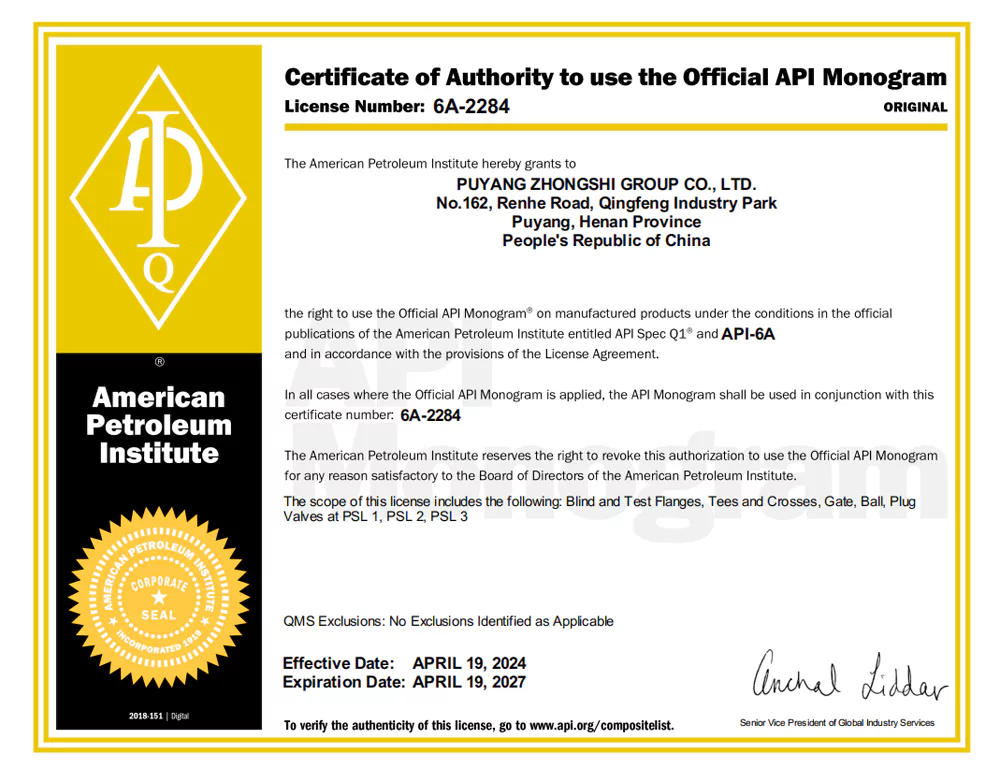

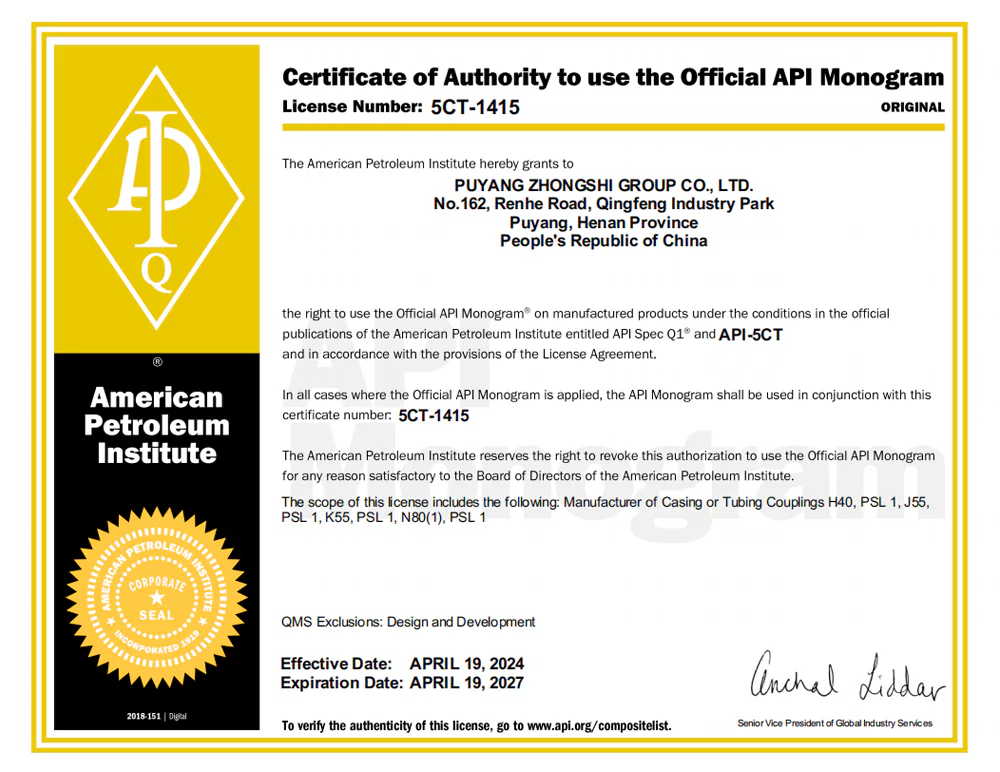

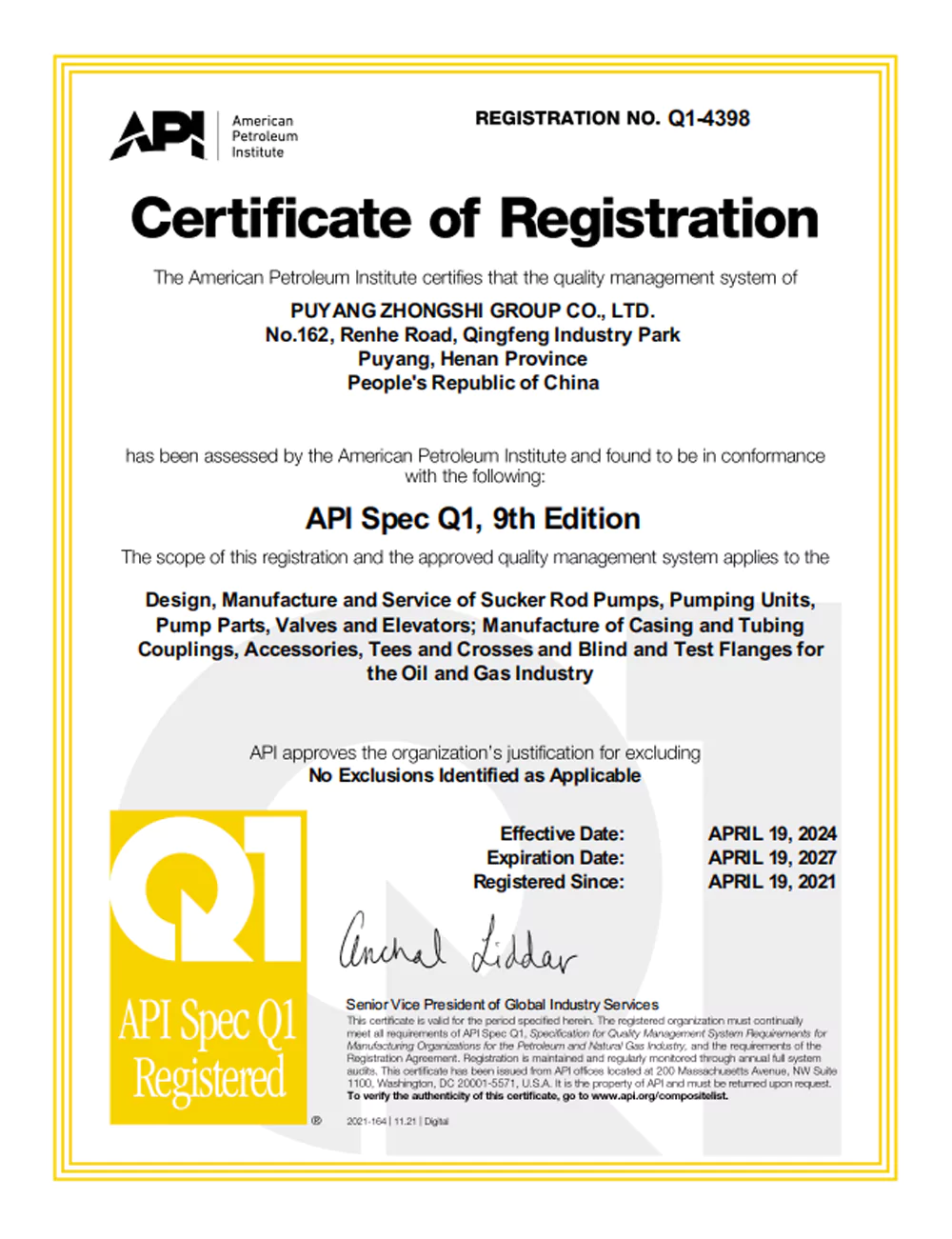

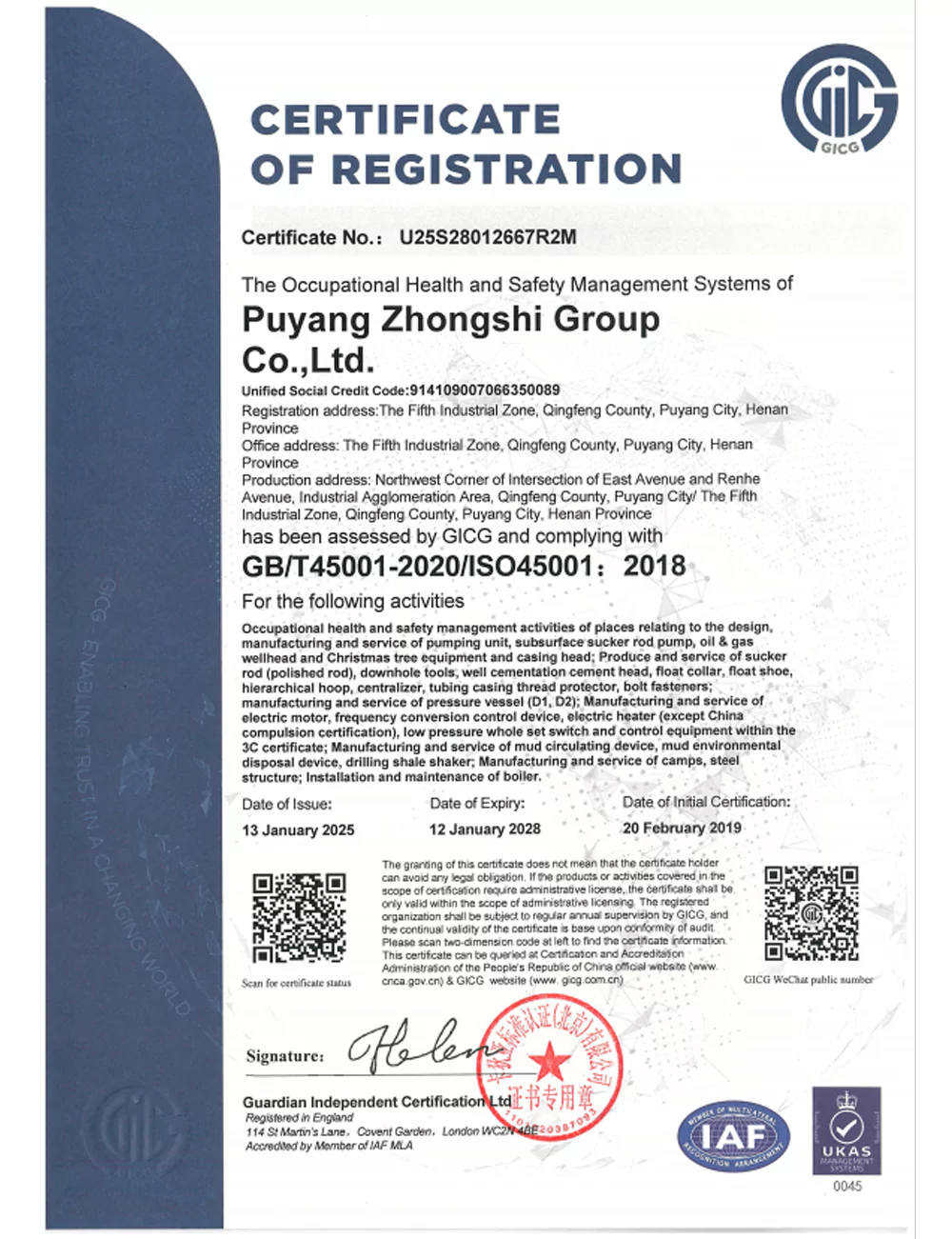

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.