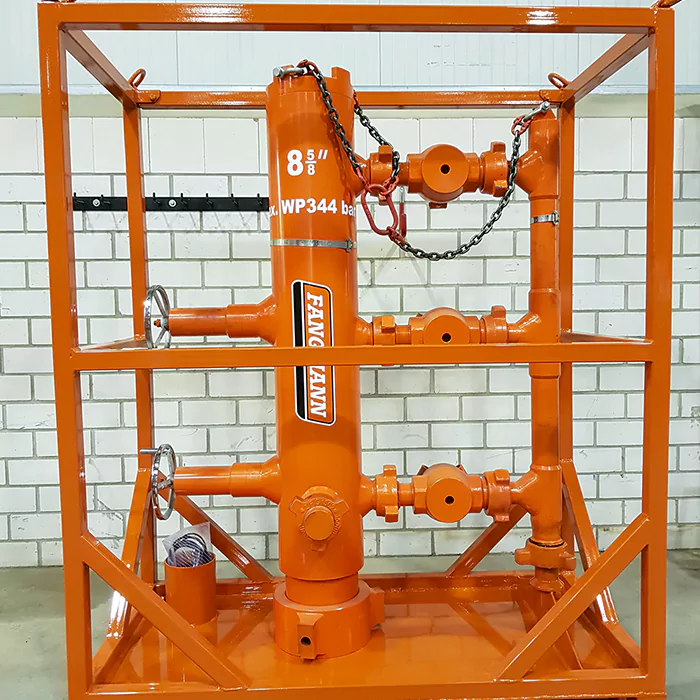

Stage Hydraulic Stage Collar DV Tool

What is Stage Hydraulic Stage Collar?

The Stage Hydraulic Stage Collar is a tested and reliable tool designed to perform staged cementing in wells of any angle, including horizontal sections. It can be positioned anywhere in the casing string. This collar is PDC-drillable and features a shear pin system that can be adjusted on-site for custom pressure settings.

Appilcation of Stage Hydraulic Stage Collar

The Hydraulic Stage Collar is essential for modern, complex well construction where a mechanical tool would be unusable.

High-Angle / Horizontal Wells (Mandatory): This is the primary application. In a horizontal section, a heavy mechanical plug will simply not fall, and may stick to the low side of the casing. The hydraulic system guarantees tool activation regardless of the wellbore angle.

Deep Wells / HPHT (High-Pressure/High-Temperature): The hydraulic system offers more precise control over opening pressure, which can be critical in sensitive HPHT environments.

Through-Drillpipe or Complex Intervention Jobs: In certain specialized operations (though less common than standard casing runs), the hydraulic method is easier to manage when pumping through a smaller-diameter work string.

data sheet of Stage Hydraulic Stage Collar

| Size | 51/2" 7" | 7" |

|---|---|---|

| Length, mm | 930 | 956 |

| Max.Diameter, mm | 168 | 210 |

| Opening pressure, Mpa | 17-18 | 17-18 |

| Closing Pressure, Mpa | 8-10 | 8-10 |

| Opening Casing Diameter, mm | 87.31 | 114.3 |

| DN, mm | 123.03 | 157.48 |

| Closing plug length, mm | 267 | 273 |

| Closing plug bowl diameter, mm | 135 | 169.86 |

| Open dart length, mm | 312.74 | 381 |

| Shut off plut length, mm | 391.32 | 422.26 |

| Shut off plug bowl Diameter, mm | 139.7 | 173.83 |

| Baffle ring ID, mm | 71.12 | 77.44 |

| Baffle ring OD, mm | 153.67 | 200.03 |

Mechanical Stage Collar V.S. Hydraulic Stage Collar

| Feature | Stage Mechanical Stage Collar (MC) | Stage Hydraulic Stage Collar (HC) |

|---|---|---|

| Opening Mechanism | Activated by a gravity-fed, free-fall opening plug/dart that lands on a seat. | Activated by a pumped hydraulic ball or special plug that lands on a seat. |

| Primary Force | Gravity is critical for the dart/plug descent. | Hydraulic Pumping Pressure is the sole driver. |

| Structure | The internal seat and sleeve are designed to interface with the larger, heavier mechanical dart. | The internal seat (ball seat) is designed to securely seal around a high-pressure ball or plug. |

| Well Suitability | Vertical / Low-Deviation Wells (Ideal ≤ 30° deviation). | High-Angle / Horizontal Wells (Required for ≥ 45° deviation). |

| Operational Risk | Risk of the opening dart/plug sticking or failing to land in a high-angle section. | Risk of the hydraulic ball/plug failing to seal properly under pressure or being pumped out prematurely. |

| Drill-Out Time | Generally takes slightly longer to drill out if the dart/plug is heavier or more metallic. | Often designed for faster drill-out with smaller, engineered components. |

Get Quotation

Stage Hydraulic Stage Collar DV Tool

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

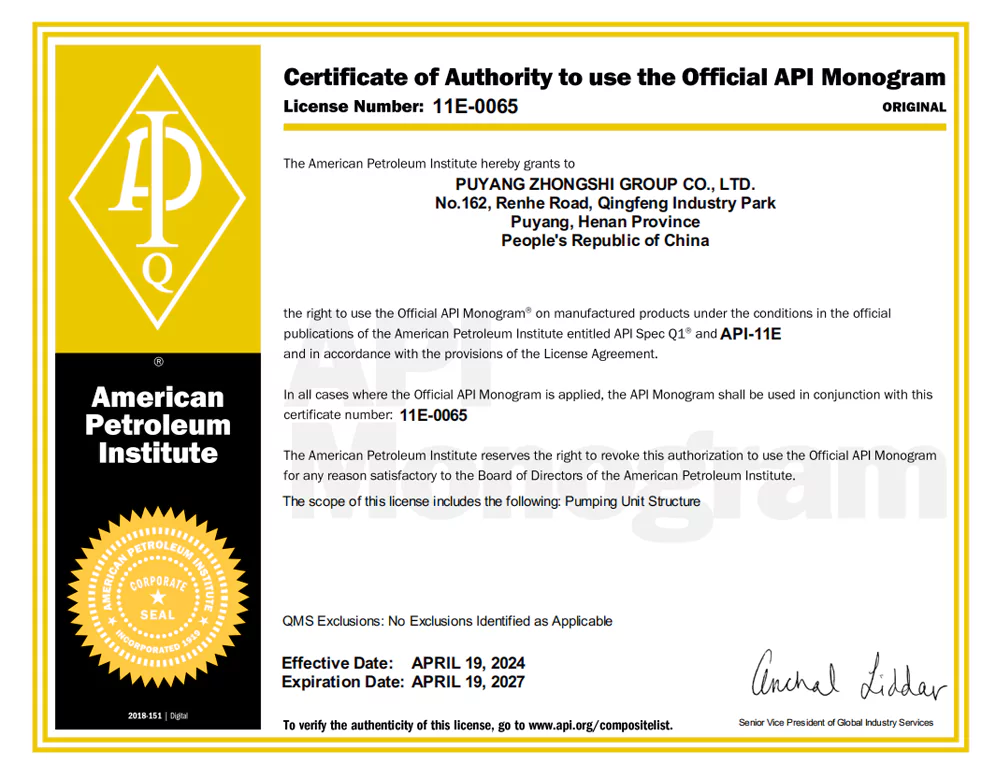

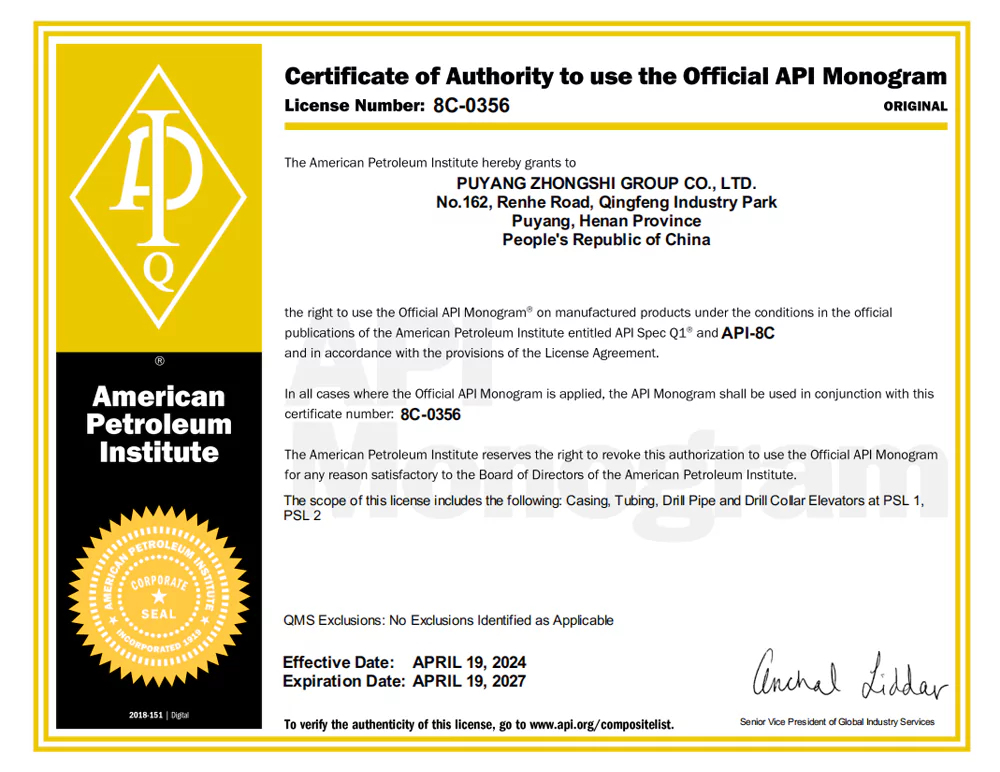

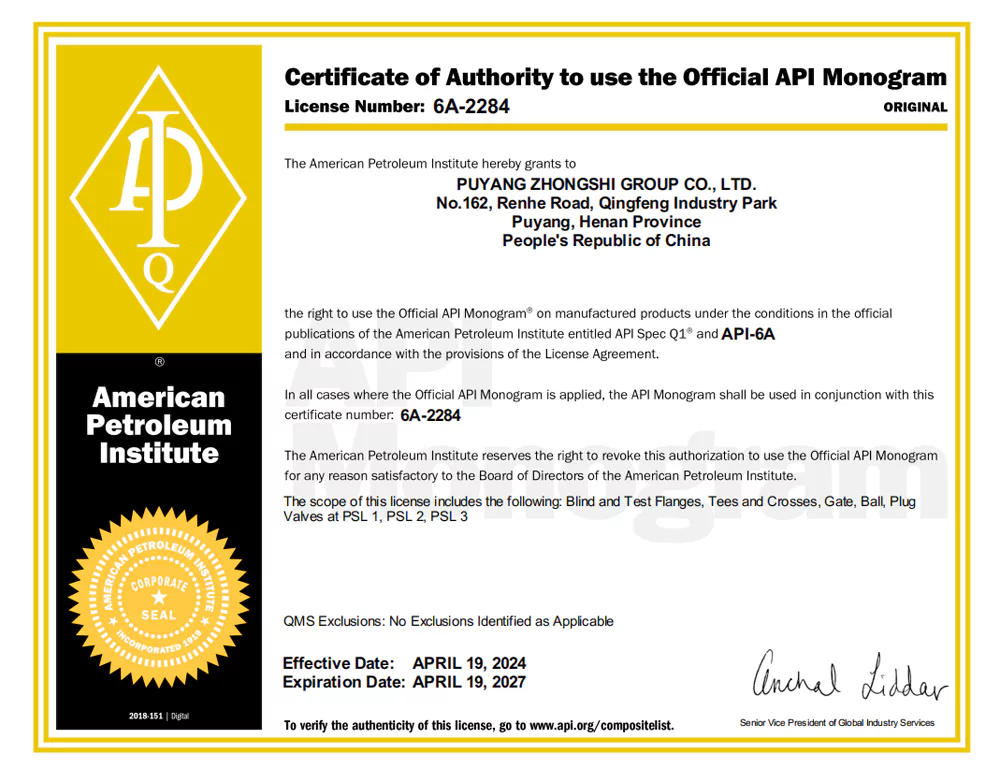

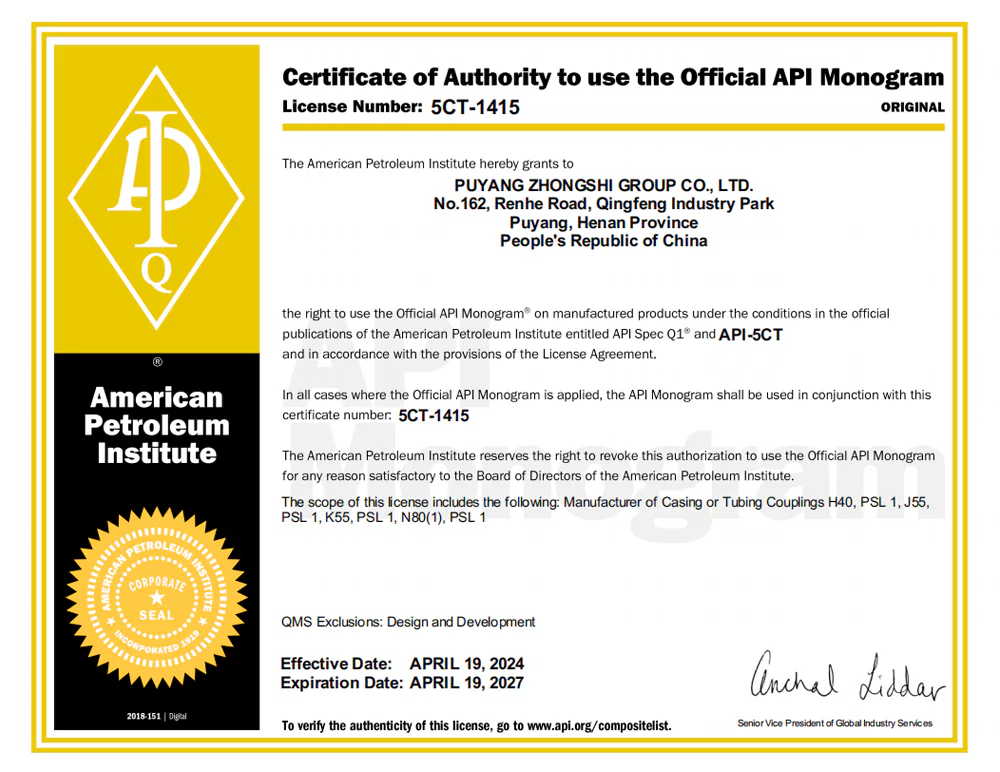

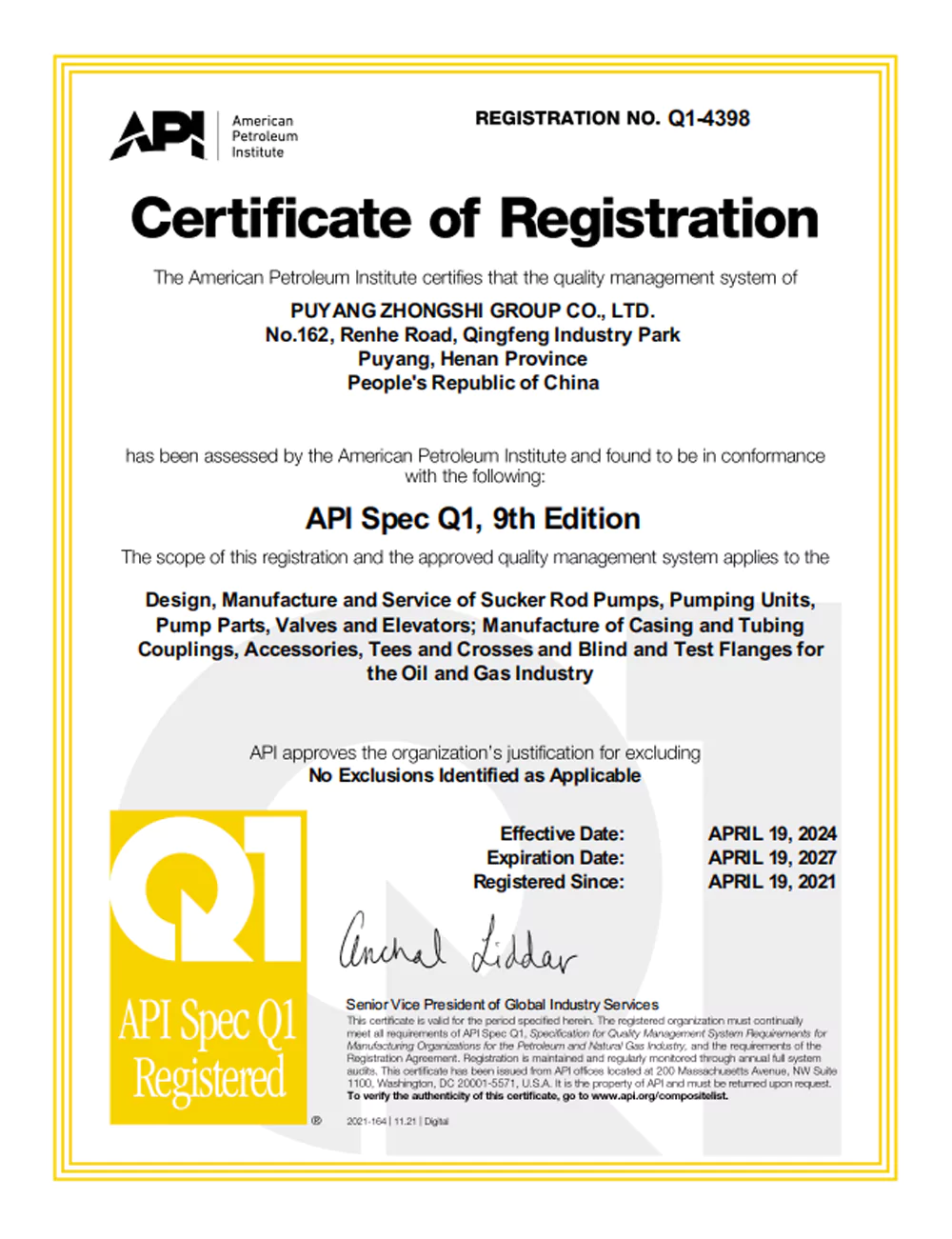

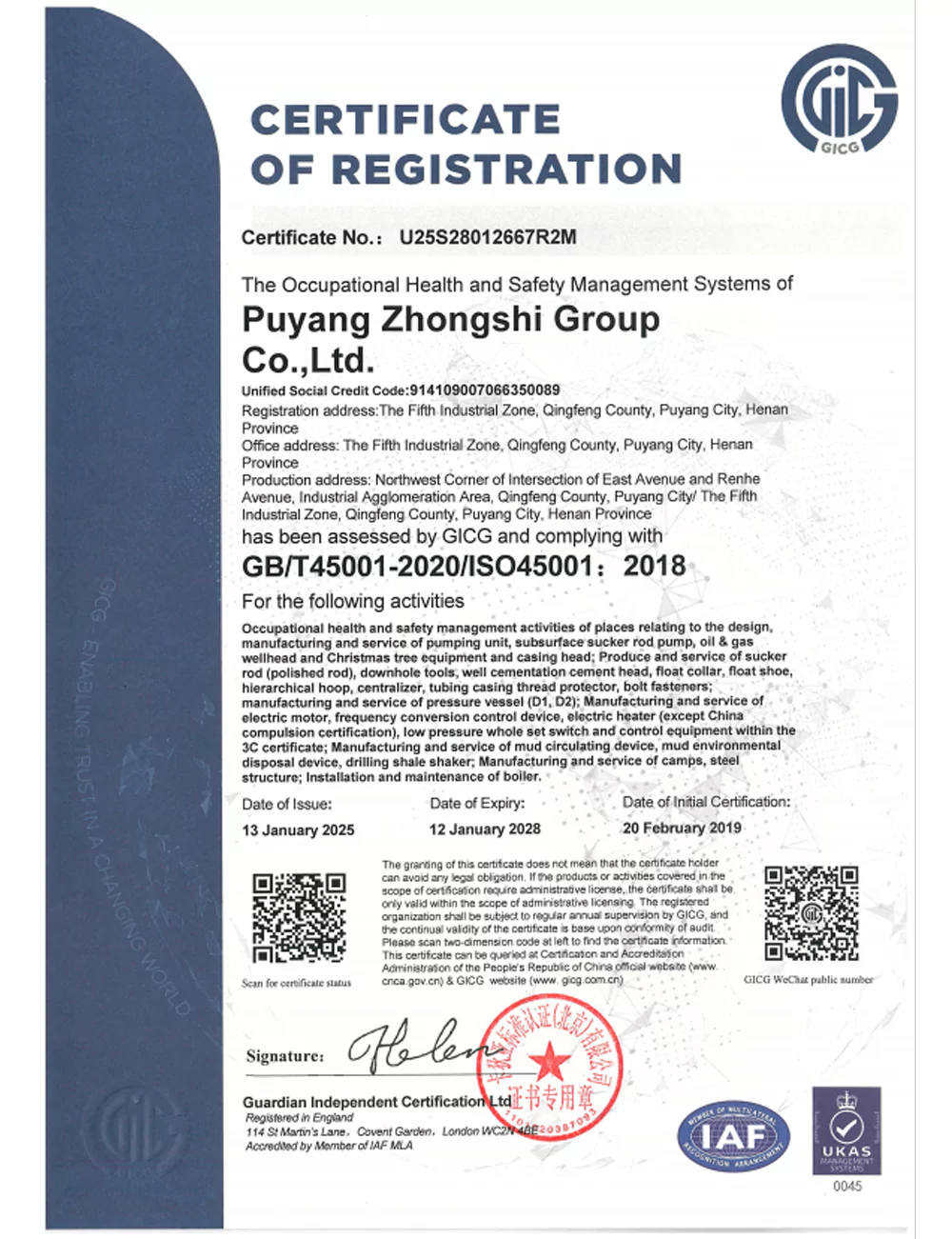

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.