Slip On Set Screw Stop Collar

A Slip On Set Screw Stop Collar is a one-piece stop ring that is installed by slipping it over the end of the casing pipe. Once it reaches the desired location, it is secured by tightening one or more set screws that bite into the surface of the casing. Puyang Zhongshi Group is the many years supplier for world famous oilfield service companies for different types of cementing tools including the stop collars. Contact us to get a detailed quotation today!

What is a Slip On Set Screw Stop Collar?

A Composite Centralizer is a non-metallic, rigid-body cementing tool made from advanced, high-strength composite materials. These typically involve reinforcing fibers (like fiberglass or carbon fiber) set within a durable polymer resin matrix (such as high-grade nylon, epoxy, or polyurethane).

Composite centralizer is engineered to combine the fixed-standoff stability of a rigid centralizer with the low-friction and corrosion-resistant properties of advanced materials. They feature external, often spiral-shaped, blades that wrap around the casing pipe to ensure it is centered in the wellbore annulus.

Key advantages of Slip On Set Screw Stop Collar

High Holding Force: The set screw(s) provide a powerful, positive mechanical lock against axial movement, which is far superior to the friction-only hold of a pure Slip-On (Friction) collar.

Structural Integrity: As a single-piece ring, it generally offers greater structural rigidity than hinged collars, as there is no hinge mechanism that could potentially fail.

Cost-Effective: It is often a more cost-effective choice than heavy-duty bolted or welded collars while still offering sufficient holding power for many applications.

Slip On Set Screw Stop Collar is suitable for

This collar type is suitable for applications that require a strong, reliable mechanical hold but allow for the slight surface damage caused by the set screws.

Medium to High-Deviation Wells: The set screw mechanism provides a strong mechanical lock, which is necessary to resist the medium to high drag forces encountered when running casing in wells that are not strictly vertical.

Standard Carbon Steel Casing: It is typically used with standard-grade casing where the slight scoring from the set screws is not a major metallurgical concern.

Preventing Movement of Accessories: Its primary role is to secure casing centralizers (like bow-spring or solid-body types) or cement baskets in place, ensuring they don’t move axially while the casing is being run or reciprocated.

Situations Requiring Simplicity: Since it is a single-piece unit (unlike a hinged collar), it has fewer parts, which some operators prefer for simplicity, provided they can slide it onto the casing before connecting the joint.

data sheet of Slip On Set Screw Stop Collar

| Size (mm) / (in) |

OD (mm) |

ID (mm) |

Height (mm) |

Weight (KG) |

Screws Nos. | Part No. |

|---|---|---|---|---|---|---|

| 114 4-1/2 |

127 | 117 | 40 | 0.45 | 6 | CWSC114 |

| 140 5-1/2 |

152 | 143 | 40 | 0.62 | 8 | CWSC140 |

| 168 6-5/8 |

184 | 172 | 40 | 0.95 | 8 | CWSC168 |

| 178 7 |

194 | 182 | 40 | 1 | 8 | CWSC178 |

| 194 7-5/8 |

210 | 198 | 40 | 1.2 | 8 | CWSC194 |

| 219 8-5/8 |

232 | 222 | 40 | 1.4 | 8 | CWSC219 |

| 244 9-5/8 |

264 | 248 | 40 | 2.1 | 8 | CWSC244 |

| 273 10-3/4 |

298 | 277 | 40 | 2 | 8 | CWSC273 |

| 340 13-3/8 |

365 | 345 | 40 | 3.5 | 12 | CWSC340 |

| 406 16 |

430 | 412 | 40 | 3.8 | 16 | CWSC406 |

| 473 18-5/8 |

500 | 480 | 40 | 4.5 | 16 | CWSC473 |

| 508 20 |

530 | 514 | 40 | 4.4 | 16 | CWSC508 |

Get Quotation

Slip On Set Screw Stop Collar

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

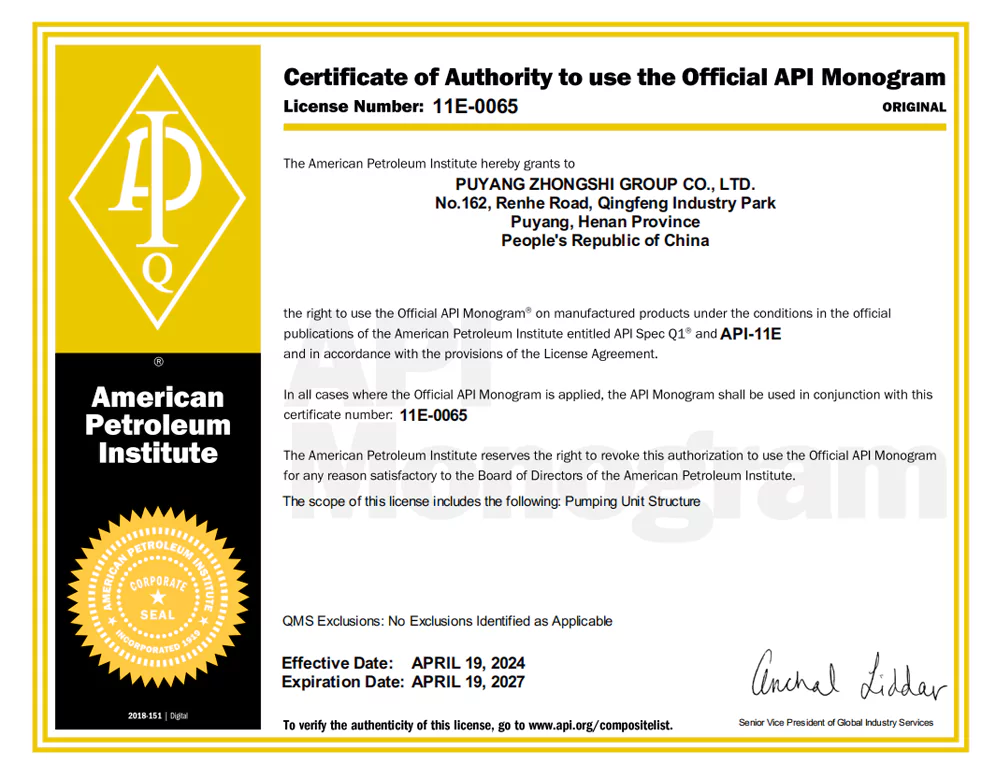

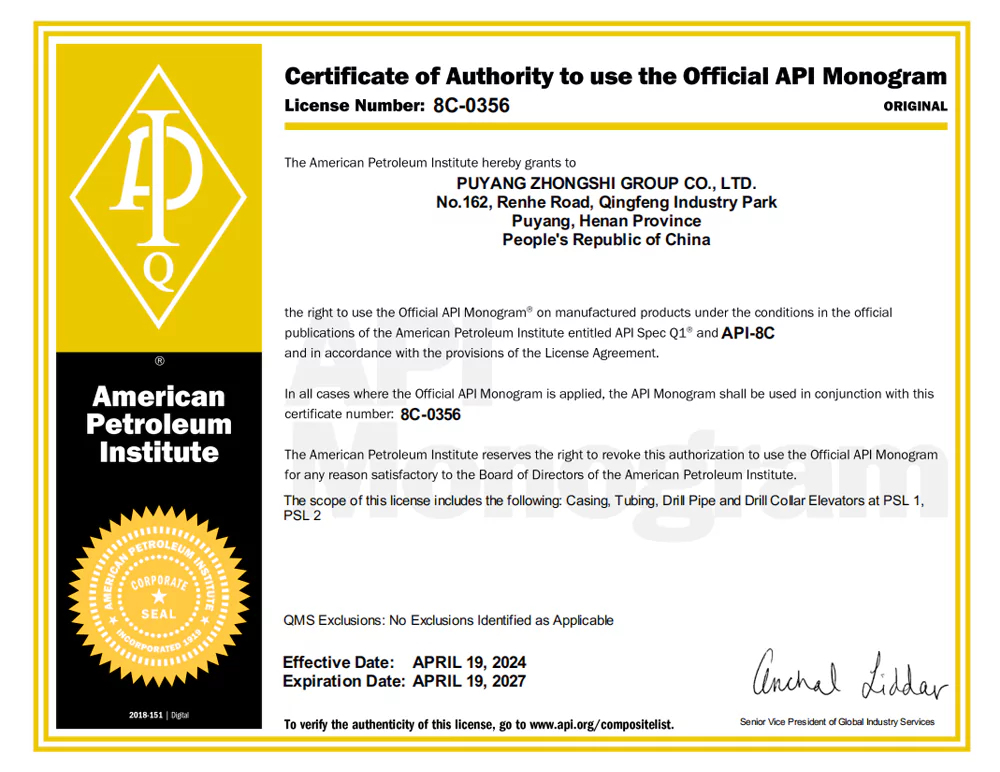

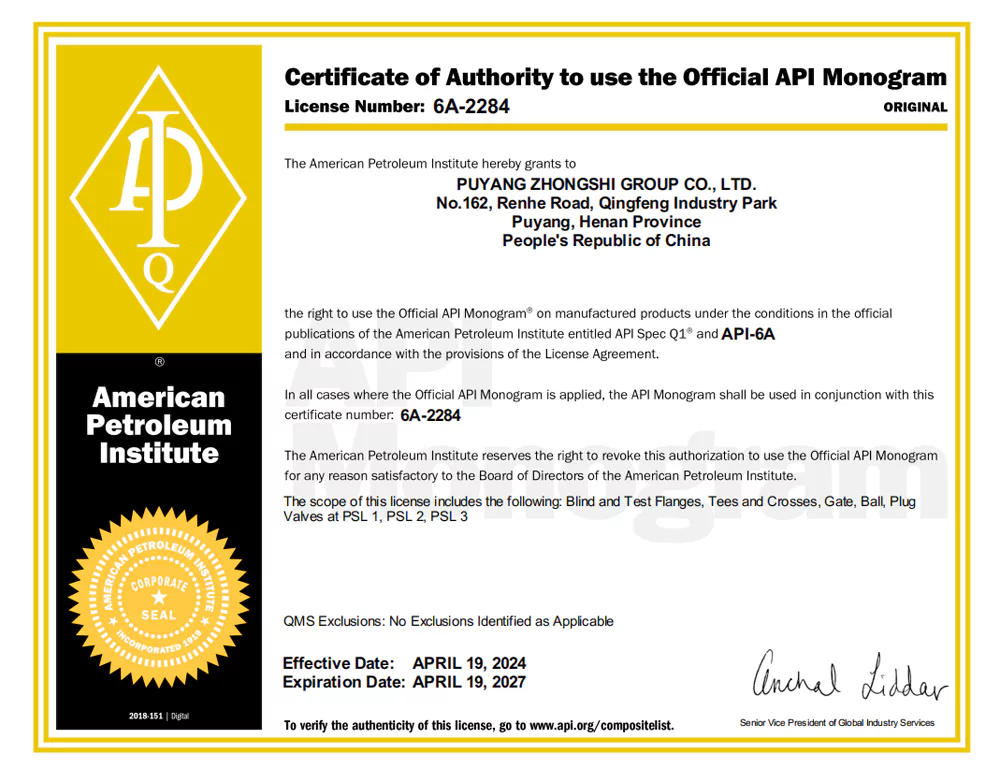

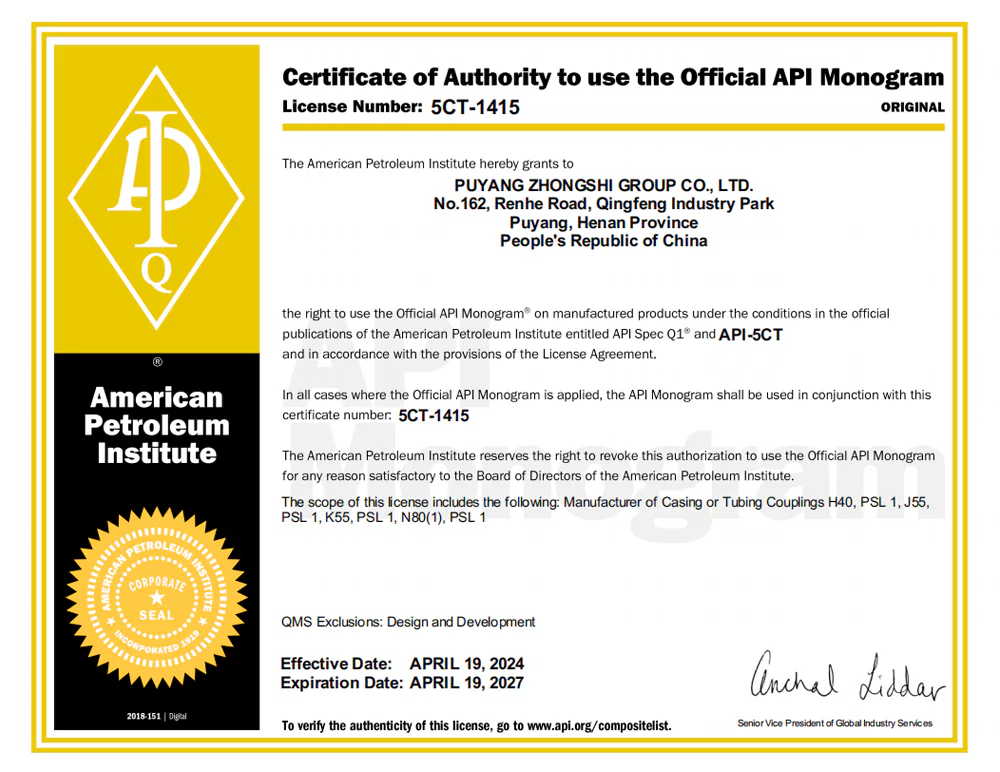

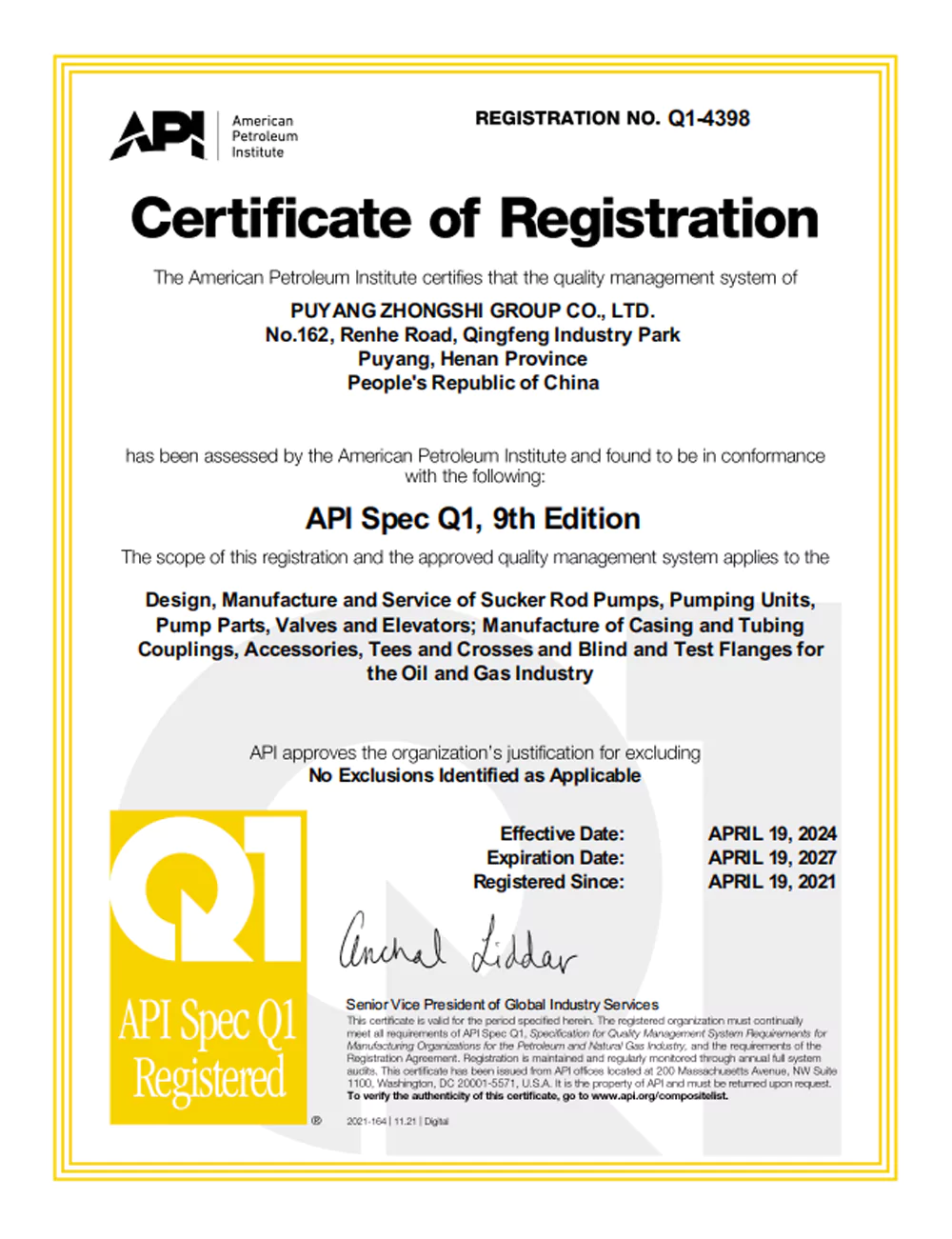

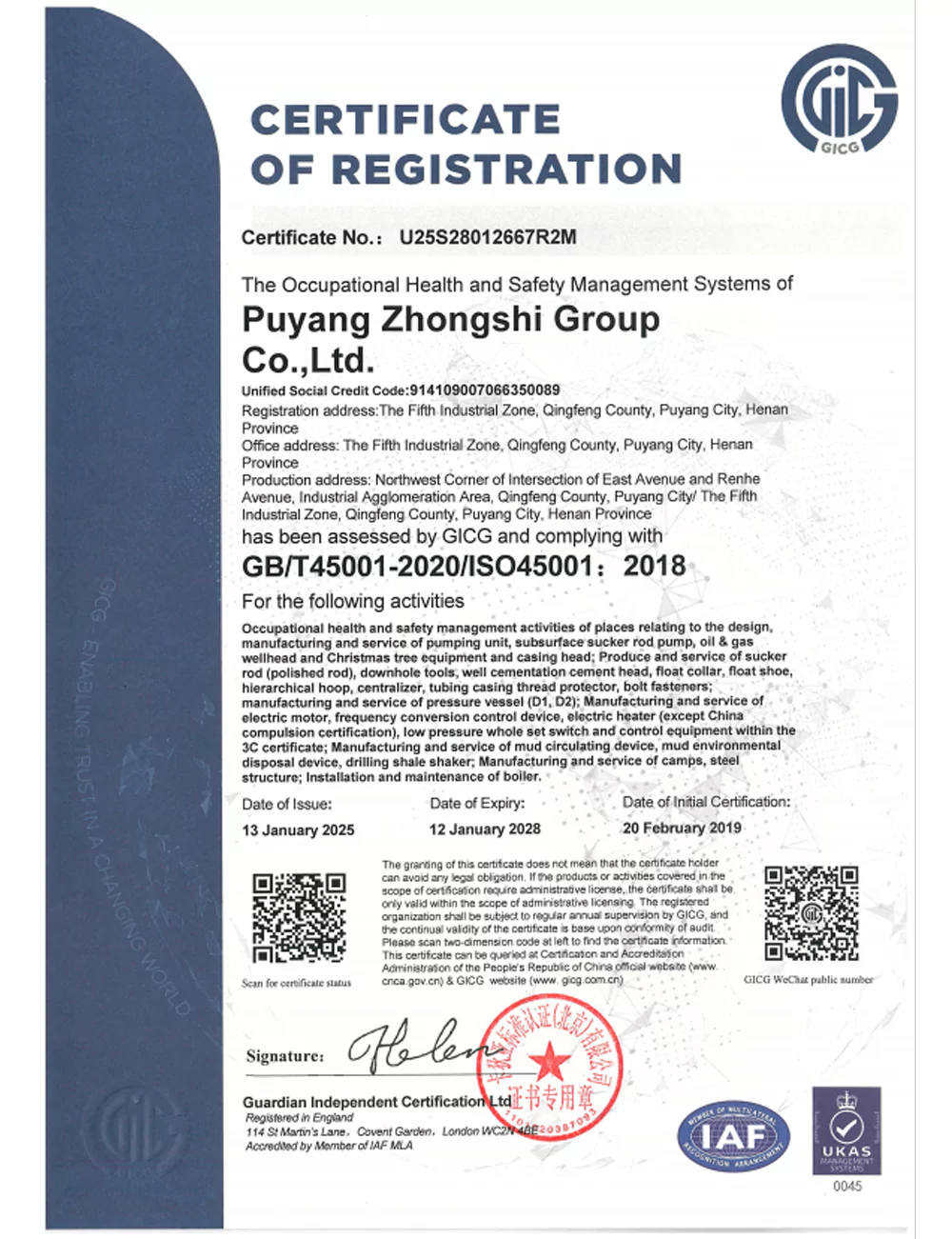

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.