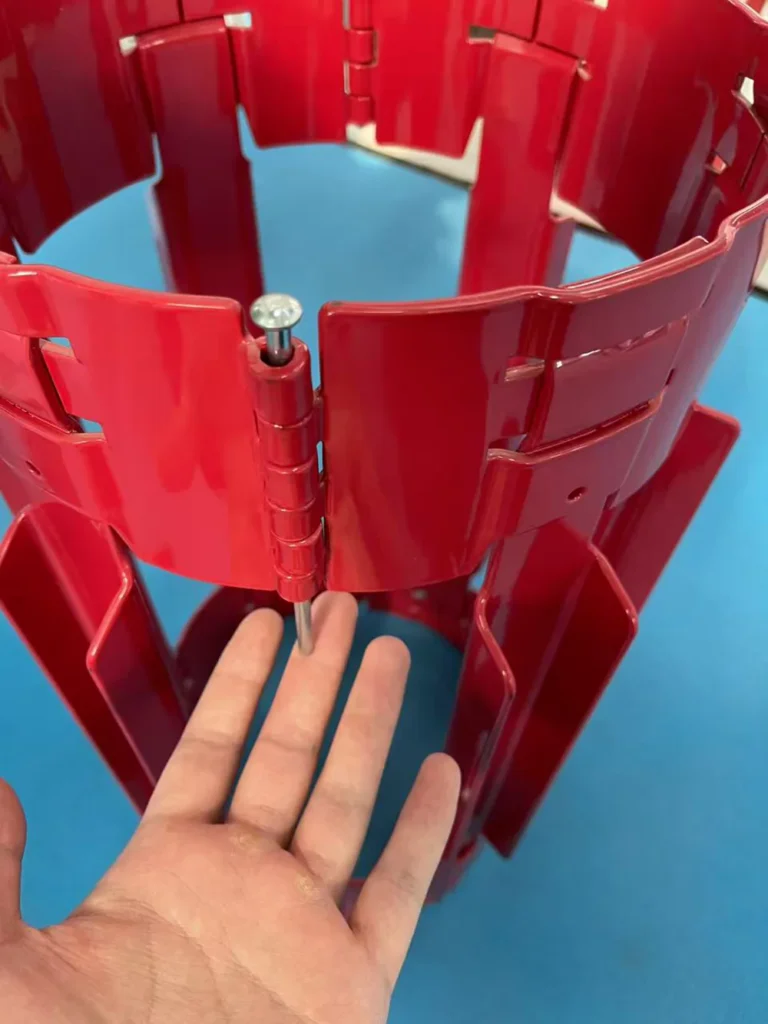

Positive Centralizer

Positive Centralizer, also called semi-rigid centralizer, can provide maximum and reliable casing standoff while offering superior flow dynamics, especially when compared to conventional, lighter-duty bow-spring centralizers. Choose Puyang Zhongshi Group Co Ltd Positive Centralizer for guaranteed wellbore cementing process!

What is a Positive Centralizer?

A Positive Centralizer is a specialized type of casing centralizer engineered for high-performance applications, balancing the flexibility of a bow-spring with the strength of a rigid centralizer. In some areas it is often called as Semi-Rigid Centralizer or a specific high-performance version of a Rigid Bow Centralizer.

Most modern Positive Centralizers are a variant of the Non-Welded Hinged Bow Spring design. This design prioritizes a high Restoring Force (the strength to push the casing back to center) while maintaining a low Running Force (drag) to minimize the risk of the casing getting stuck. The bows are often thicker, wider, or specifically shaped to provide a much more rigid and predictable standoff compared to conventional bow springs, often achieving near 100% standoff in cased-hole or tight tolerance applications.

Key Advantages of positive centralizer

High Restoring Force-to-Drag Ratio: This is its most significant advantage. It generates a high force to center the pipe but is designed to minimize friction while running in the hole (low running force). This reduces the risk of casing sticking in long lateral sections.

Superior Flow Dynamics: The straight or slightly angled U-profile bars (instead of thin bows) maximize the flow area in the annulus. This aids in creating turbulent flow necessary for optimal mud removal, which is essential for a successful primary cement job.

Enhanced Durability (Non-Welded): The bows are mechanically locked to the collars, eliminating the brittle weak points associated with traditional welded centralizers. This increases the tool’s resilience when encountering downhole obstructions or when the casing is rotated during cementing.

Easy Field Installation (Hinged): Most Positive Centralizers are hinged (latch-on), allowing the rig crew to quickly assemble the two halves around the casing joint on the rig floor.

Positive Centralizer is suitable for

The Positive Centralizer is engineered to succeed where traditional bow-spring centralizers lack the necessary strength to overcome gravitational and frictional forces.

Deviated & Horizontal Wells: Provides the high, consistent restoring force needed to lift the heavy casing off the low side of the wellbore, ensuring the cement sheath is uniform.

Liner Overlaps & Cased-Hole Runs: Ideal for running inside existing casing. Its rigid profile often guarantees a precise, near 100% standoff in the tight annular space between the liner and the previous casing.

High Mud Displacement Wells: The U-profile or flat-bar design often provides maximum fluid passage and creates turbulence (turbolizing effect) in the cement slurry, effectively cleaning mud cake and improving zonal isolation.

Challenging Geometries: Used in sections with severe doglegs or restricted wellbores. Its semi-rigid nature allows the bows to compress in tight spots but rapidly spring back to provide centralization immediately after passing the restriction.

data sheet of Positive Centralizer

| Size (in) | OD (mm) |

ID (mm) |

Length (mm) |

Weight (KG) |

Part No. | |

|---|---|---|---|---|---|---|

| ID | OD | |||||

| 7 | 8-1/2 | 212 | 182 | 500 | 5.3 | SR07000812 |

| 9-5/8 | 12-1/4 | 306 | 250 | 505 | 7.1 | SR09581214 |

Get Quotation

Positive Centralizer

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

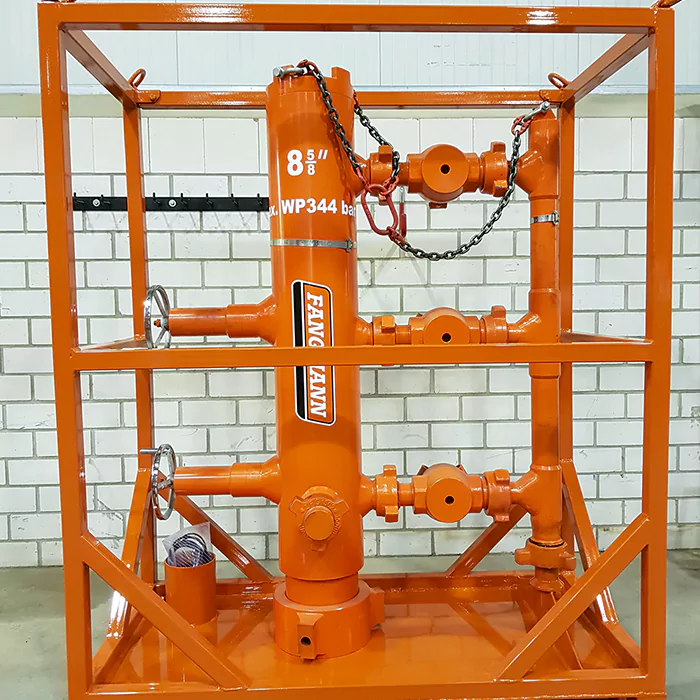

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

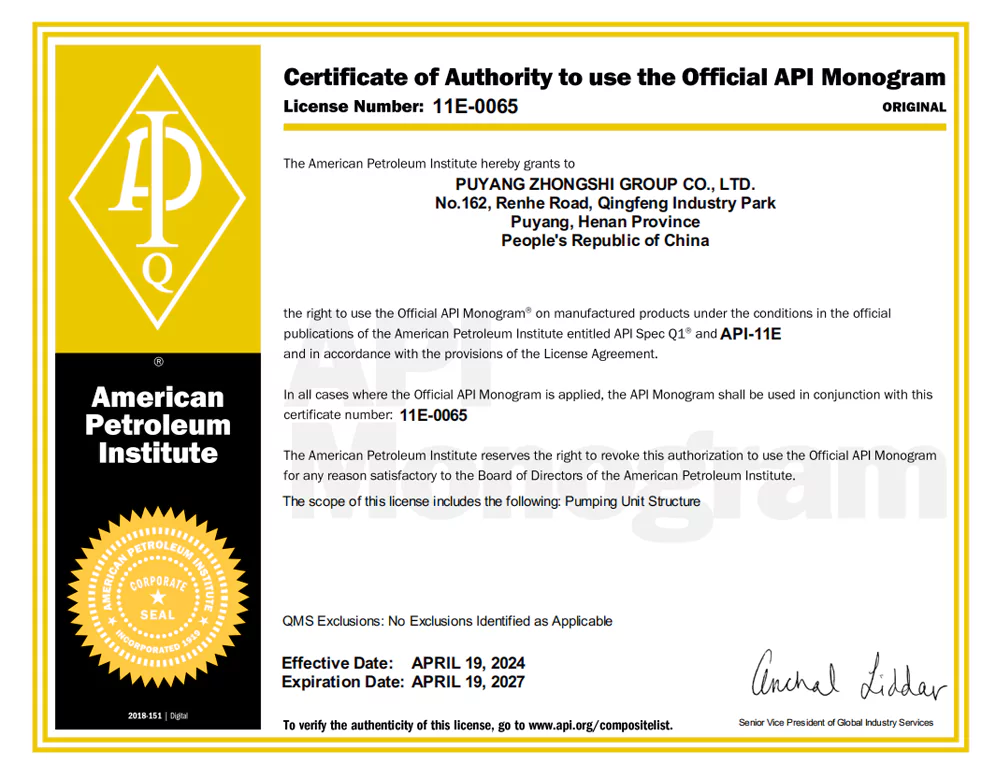

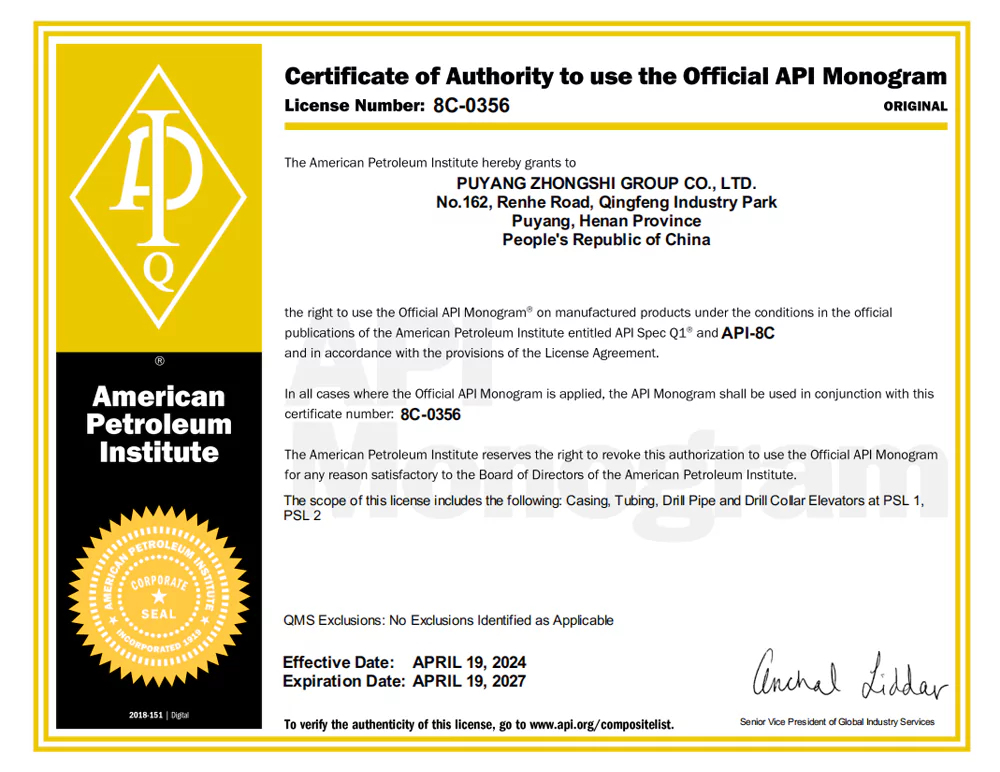

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.