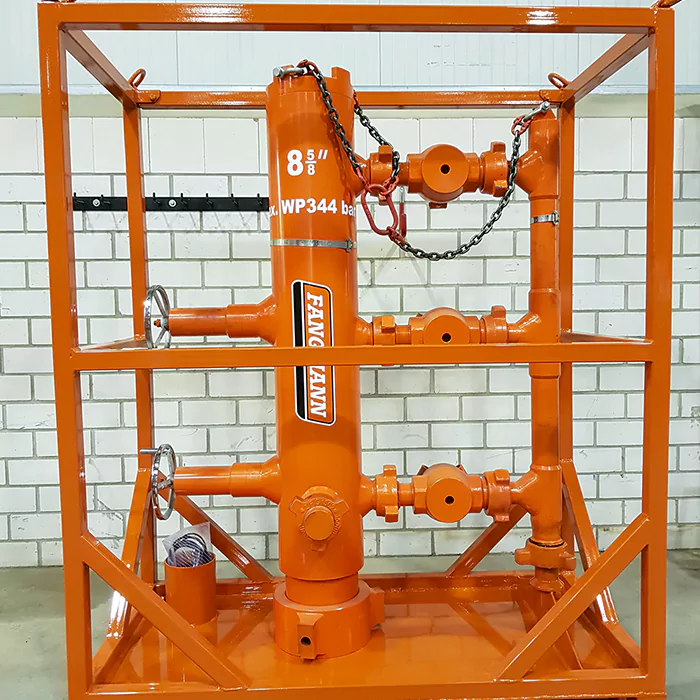

Non-Rotating Casing Float Shoe

A non-rotating casing float shoe is a specialized piece of oilfield equipment attached to the very bottom of a casing string. Its primary purpose is to guide the casing to its full depth in the wellbore and to prevent the backflow of cement slurry after it has been pumped into the annulus. The key feature of a non-rotating float shoe is its anti-rotation mechanism, which is an internal profile or insert designed to engage with a corresponding non-rotating cementing plug. Puyang zhongshi group co ltd is the oilfield tools manufacturer and supplier since 1997 fully API certificed. Contact us to get more details!

What is Non-Rotating Casing Float shoe?

A non-rotating casing float collar is a specialized type of float collar used in oil and gas drilling, primarily during cementing operations. Like a standard float collar, its main job is to prevent the backflow of cement and to provide a landing point for cementing plugs. However, what makes it unique is its anti-rotation mechanism.

features of this non-rotating casing float shoe

- The upper part of the valve is equipped with an anti-rotation disk and a rubber plug, both made from drillable materials.

- The valve body is constructed from phenolic resin, and the spring is made of tin bronze. The overall performance meets the requirements of API RP 10F IIIC standards.

- The internal cementing uses high sulfur-resistant oil well cement, which offers excellent drillability and erosion resistance.

- Thread processing and inspection are performed in accordance with API 5B standards.

- The float shoes and float collars are available in single or double-valve designs. The anti-rotation float collar and float shoes can secure the upper and lower rubber plugs, which saves time when drilling them out.

How this non-rotating casing float shoe Different from Other types?

The key feature of a non-rotating casing float shoe is its anti-rotation feature, which is an internal profile or insert designed to engage with a corresponding non-rotating cementing plug.

In conventional float shoes, the internal components can spin when a drill bit, especially a Polycrystalline Diamond Compact (PDC) bit, attempts to drill them out. This can lead to: Slower Drill-Out: The bit can “skate” over the spinning surface instead of drilling efficiently, increasing rig time and costs. Damage to the Drill Bit: The uncontrolled rotation can cause excessive wear and tear on the expensive PDC bit.

A non-rotating casing float shoe solves this problem. When the cementing plug lands on the float shoe, the interlocking non-rotating parts lock the plug and the shoe together, preventing them from spinning. This allows the PDC bit to drill straight through the internal components quickly and smoothly.

Essentially, while all float shoes guide casing and prevent backflow, the non-rotating casing float shoe is specifically engineered for a more efficient and safer drill-out process.

data sheet of Non-Rotating Casing Float shoe

| Size (mm) / (in) |

OD (mm) |

ID (mm) |

Length (mm) |

Nozzle ID (mm) |

Thread Type | Pressure (Mpa) |

Weight (KG) |

Part No. |

|---|---|---|---|---|---|---|---|---|

| 140 5-1/2 |

160 | 127.3-118.6 | 530 | 45 | API / Premium Thread | 35 | 38 | FSBCCTNR140 |

| 168 6-5/8 |

187.8 | 153.6-144.1 | 530 | 45 | API / Premium Thread | 35 | 45 | FSBCCTNR168 |

| 178 7 |

200 | 166-150.4 | 530 | 45 | API / Premium Thread | 35 | 54 | FSBCCTNR178 |

| 194 7-5/8 |

219.1 | 178.4-162 | 530 | 45 | API / Premium Thread | 35 | 62 | FSBCCTNR194 |

| 219 8-5/8 |

244.5 | 205.6-190.8 | 530 | 45 | API / Premium Thread | 35 | 72 | FSBCCTNR219 |

| 244 9-5/8 |

269.7 | 226.6-214.3 | 530 | 70 | API / Premium Thread | 35 | 86 | FSBCCTNR244 |

| 273 10-3/4 |

298 | 258.9-242.8 | 530 | 70 | API / Premium Thread | 35 | 100 | FSBCCTNR273 |

| 298 11-3/4 |

323.9 | 281.5-273.6 | 530 | 70 | API / Premium Thread | 35 | 120 | FSBCCTNR298 |

| 340 13-3/8 |

365 | 320.4-313.6 | 530 | 70 | API / Premium Thread | 35 | 146 | FSBCCTNR340 |

| 406 16 |

431.8 | 384.1-381.3 | 580 | 70 | API / Premium Thread | 21 | 188 | FSBCCTNR406 |

| 473 18-5/8 |

508 | 450.9 | 580 | 70 | API / Premium Thread | 21 | 240 | FSBCCTNR473 |

| 508 20 |

531.2 | 485.7-475.7 | 600 | 70 | API / Premium Thread | 21 | 304 | FSBCCTNR508 |

Get Quotation

Non-Rotating Casing Float Shoe

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.