Hinged Bolted Stop Collar

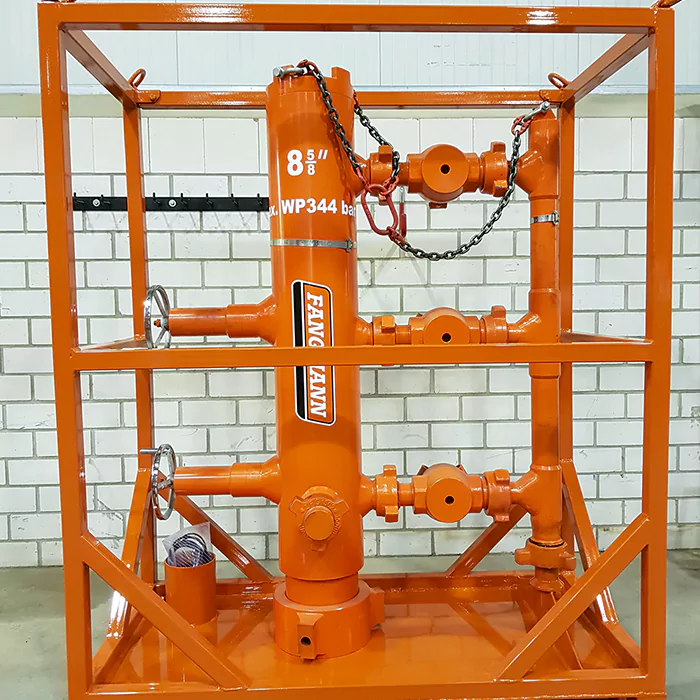

What is a Hinged Bolted Stop Collar?

A Hinged Bolted Stop Collar is a two-piece metallic ring, joined by a hinge, which can be latched onto the casing pipe at any desired position without needing to be slipped over the end of the casing joint.

It uses one or more bolts and nuts to clamp the two halves tightly around the casing circumference. The holding force is generated by the tremendous friction grip created by the uniform compressive force exerted by the tight bolts.

Key advantages of Hinged Bolted Stop Collar

The Hinged Bolted Stop Collar offers several distinct advantages, primarily related to its installation and fixation mechanism:

- Non-Marring Lock: The primary advantage is that the holding force comes from uniform compressive friction around the entire circumference of the pipe. This design does not produce marks, indentations, or punctures on the casing surface, unlike set screw types. This is vital for maintaining the structural integrity and corrosion resistance of the casing.

- Ease of Installation: The hinged, latch-on design allows the collar to be installed rapidly and easily on any part of the casing joint, saving valuable rig time.

- High, Reliable Holding Force: When torqued correctly, the powerful bolt assembly ensures the required holding strength is achieved, often exceeding API specifications [1.6].

- No Small Parts to Lose: Since the hinge and the bolt/nut assembly are often semi-permanently attached or captive, the risk of dropping small components on the rig floor is minimized (compared to separate set screws or drive pins)

Hinged Bolted Stop Collar is suitable for

This type of stop collar is suited for demanding environments where both high holding force and casing surface protection are important.

- High Axial Load Wells: Suitable for wells with high friction, such as deviated or horizontal sections, as the clamping force provides reliable holding power that can be up to 1000% of the centralizer starting force (API 10D specification)

- Mid-Joint Installation: Ideal for use on rig floors where the casing string has already been made up or where it is impractical to slide a collar over the entire joint. The hinged design allows quick installation anywhere.

- Sensitive Casing Materials: Excellent for use with high-grade, expensive casing (like CRAs) or thin-walled casing where surface integrity is critical, but the holding force is still necessary.

- Subcritical Annular Tolerances: Often designed to be economical and suitable for smaller clearance conditions.

data sheet of Hinged Bolted Stop Collar

| Size (mm) / (in) |

OD (mm) |

ID (mm) |

Height (mm) |

|---|---|---|---|

| 114 4-1/2 |

119.5 | 114.3 | 78 |

| 140 5-1/2 |

145 | 140 | 78 |

| 178 7 |

183 | 178 | 78 |

| 244 9-5/8 |

249.5 | 244.5 | 78 |

| 273 10-3/4 |

278 | 273 | 78 |

| 340 13-3/8 |

345 | 340 | 78 |

| 406 16 |

411.5 | 406.5 | 78 |

| 508 20 |

513 | 508 | 78 |

Get Quotation

Hinged Bolted Stop Collar

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

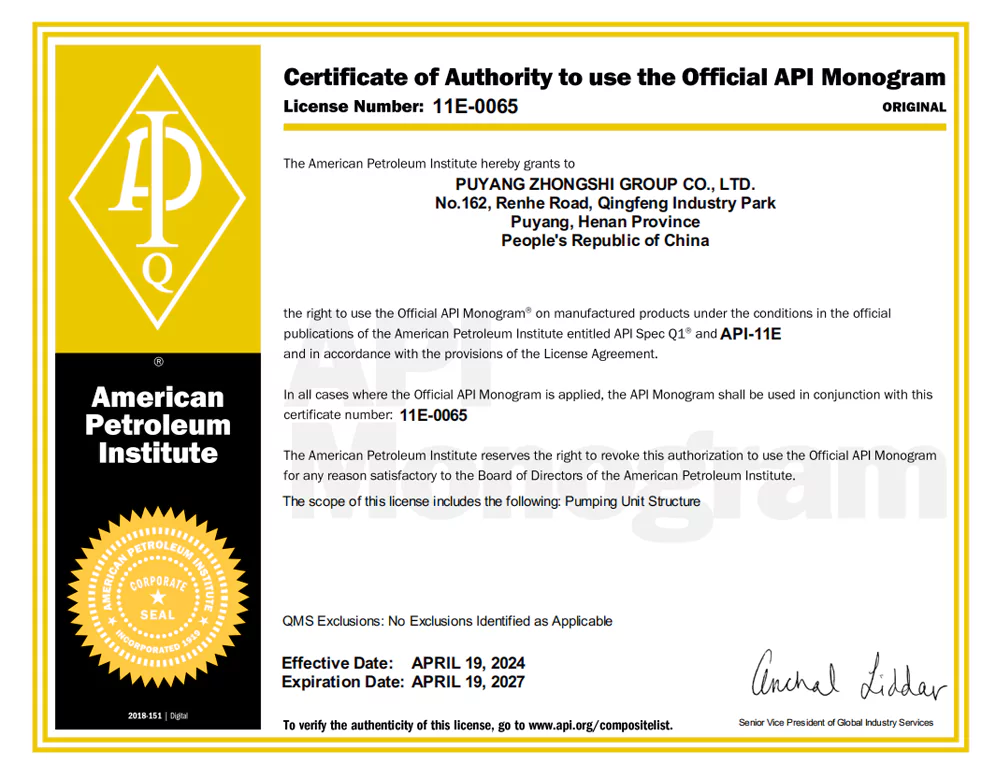

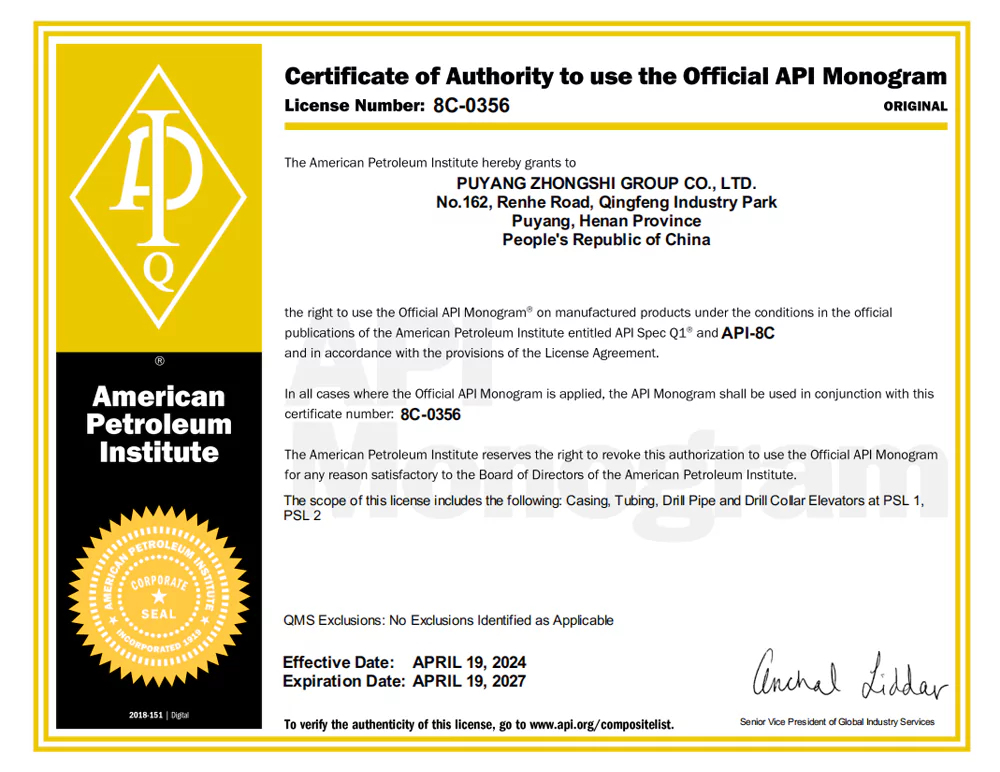

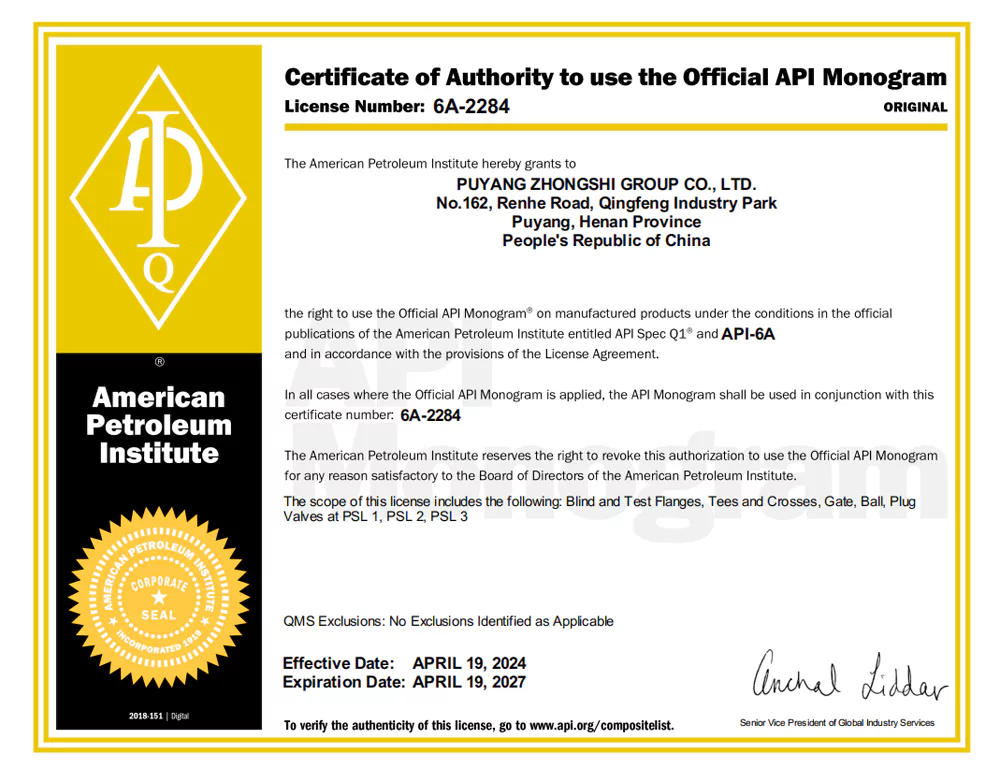

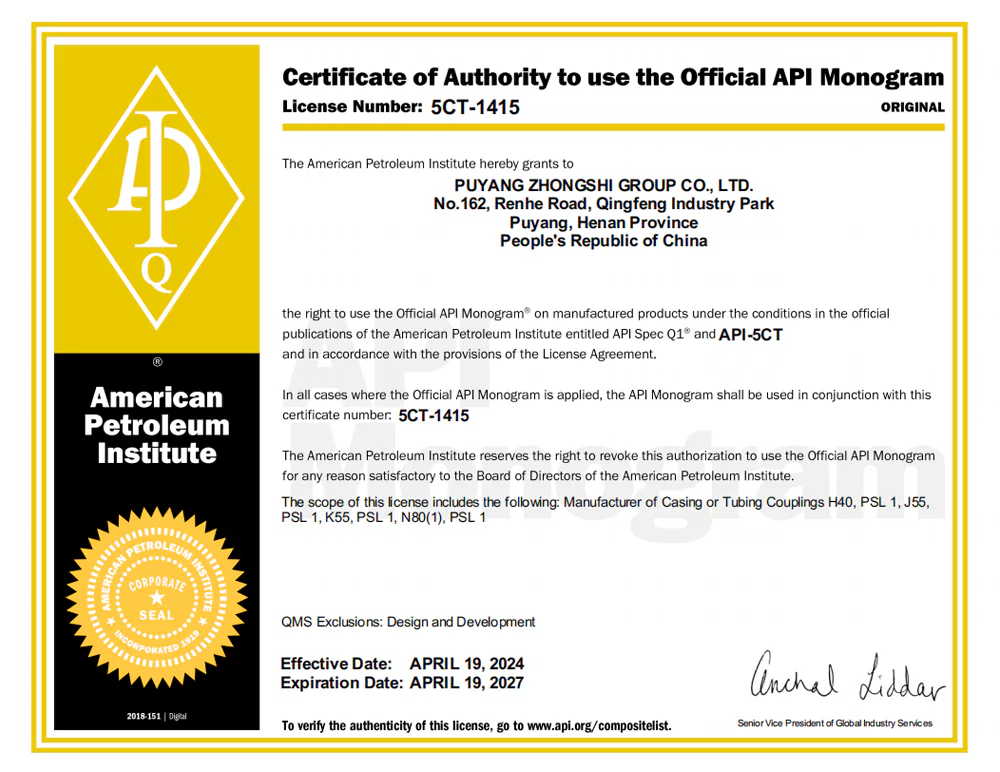

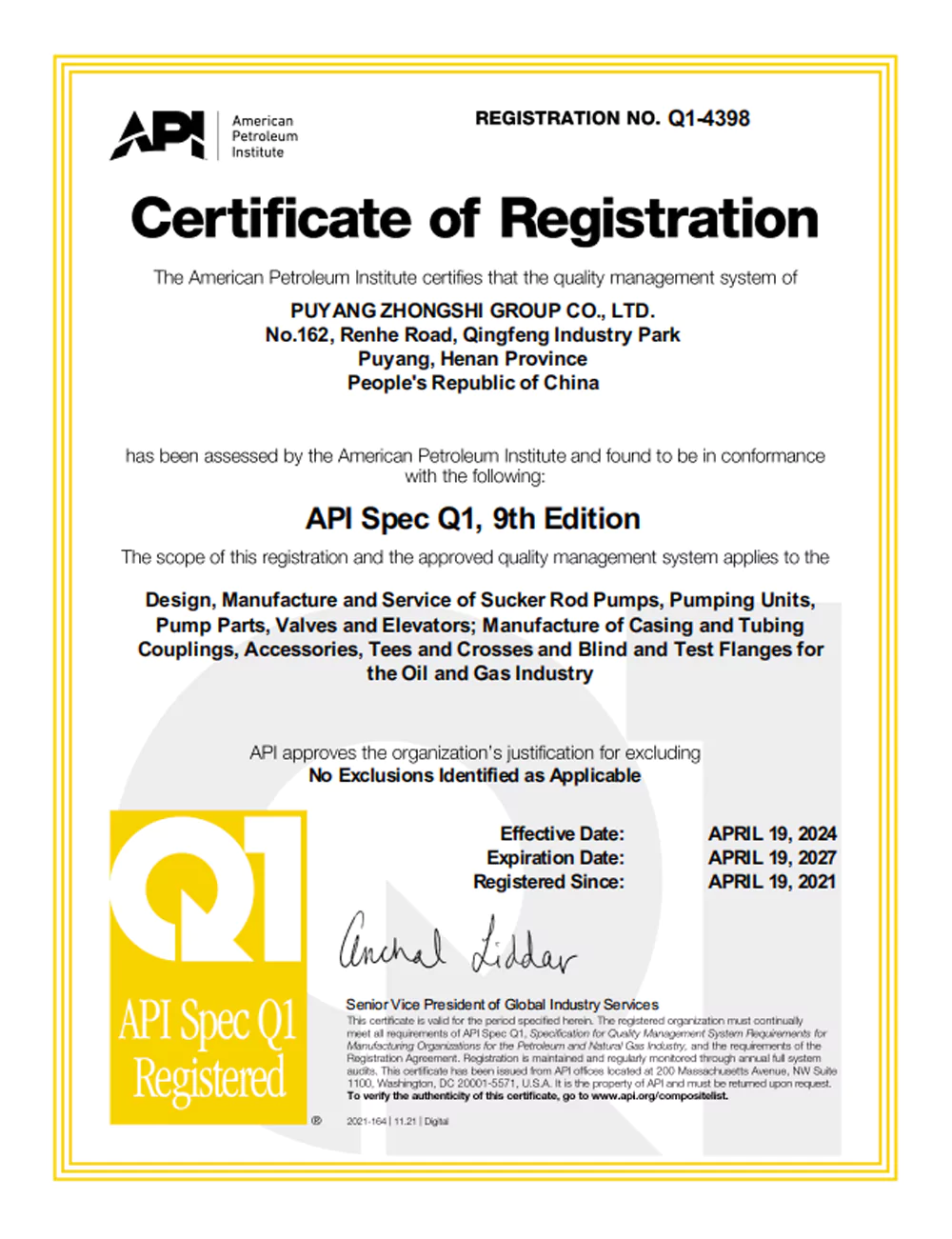

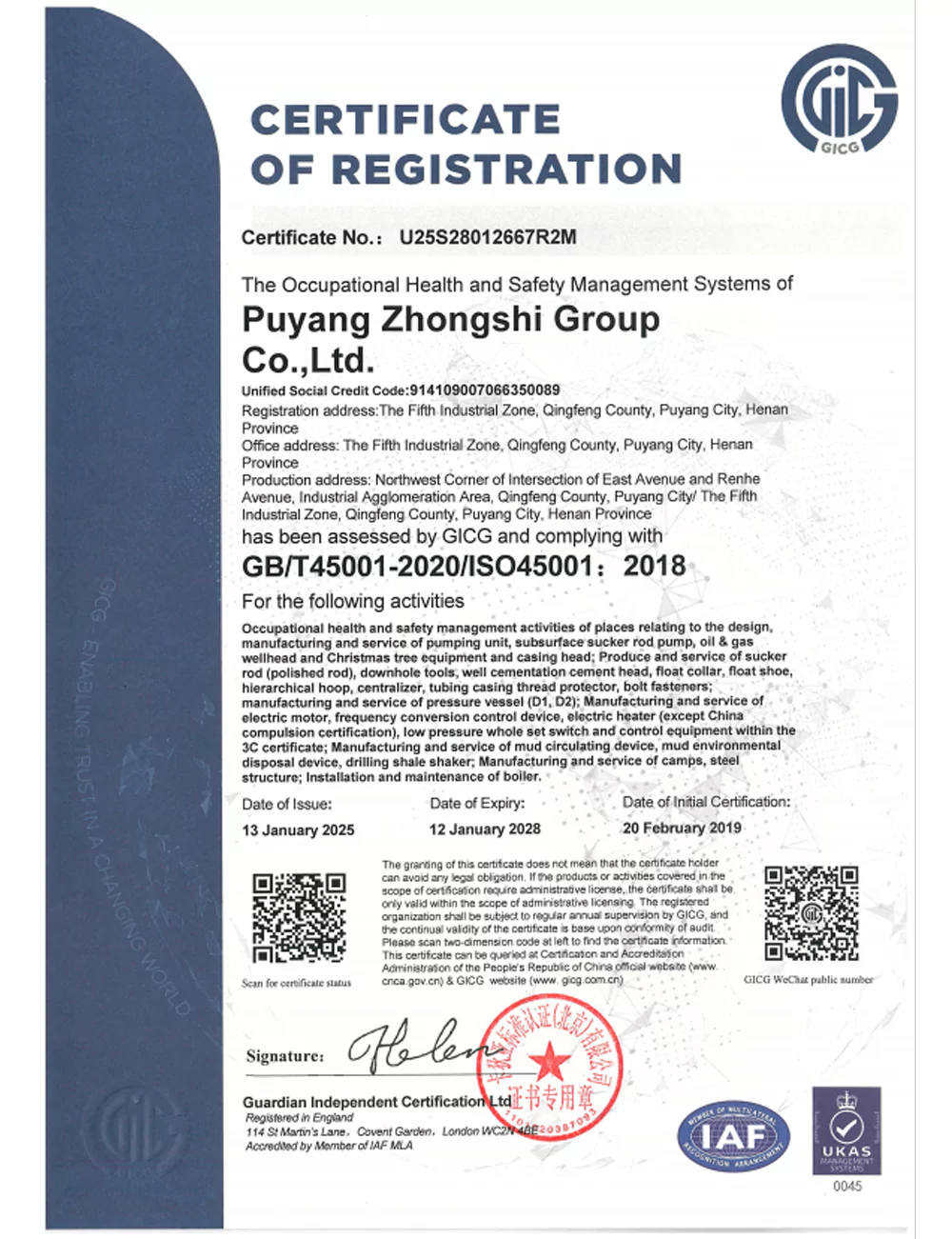

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.