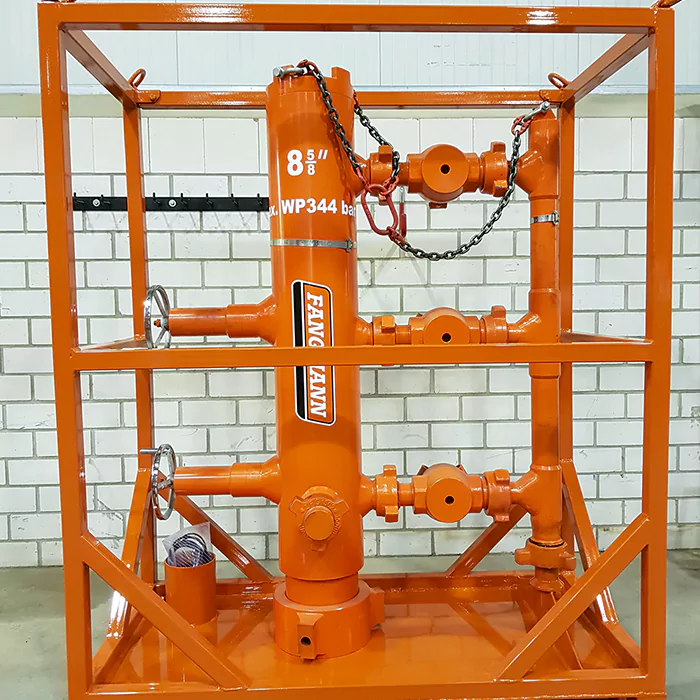

Drill Pipe Self-Lock Rubber Plug Cementing Tool

What is Drill Pipe Self-Lock Rubber Plug Cementing Tool?

The Drill Pipe Self-Lock Rubber Plug Cementing Tool is a specific type of cementing plug used to isolate and displace the cement slurry when pumping through the drill pipe or tubing string, which is run inside the larger casing or liner.

It is primarily a top cementing plug (or sometimes a system where the bottom cement plug is a ball or dart) that is launched into the drill pipe to separate the cement from the displacement fluid.

The “self-lock” mechanism implies the plug is designed to securely latch into a receiving receptacle at the end of the drill string or liner, ensuring a positive seal and preventing further flow.

Key advantages of Drill Pipe Self-Lock Rubber Plug Cementing Tool

- Liner Cementing Capability: Allows for the efficient cementing of liners (casing strings that do not extend back to the surface) by running the cement and plugs through the smaller diameter drill pipe.

- Positive Displacement and Seal: The self-lock feature ensures a strong, positive seal upon landing, giving a clear pressure signal at the surface (plug bump) to confirm the cement has been fully displaced into the annulus.

- Prevents Backflow: Once the plug is locked in place against the float equipment, it acts as a reliable barrier to prevent fluid or gas migration back up into the liner or casing.

- Minimizes Casing ID Debris: As the plug travels down the drill pipe and liner, its rubber structure (made of materials like nitrile rubber for wear resistance) effectively wipes the inner walls, which is its primary purpose.

Drill Pipe Self-Lock Rubber Plug Cementing Tool is suitable for

Liner Cementing: This is its primary application. Liners are cemented using a liner running string (drill pipe) that is disconnected after the cement job is complete. This plug seals the bottom of the liner before the drill pipe is pulled out.

Remedial Cementing: Can be used in specific remedial jobs where a small volume of cement is pumped through tubing or drill pipe to set a plug in the wellbore.

Long and Highly Deviated Wells: Used where running a conventional cementing head and full-casing plugs is impractical due to string length or high deviation.

data sheet of Drill Pipe Self-Lock Rubber Plug Cementing Tool

| Size (mm) / (in) | OD (mm) | Body Diameter (mm) | Height (mm) | Casing Weight (IB/FT) | |

|---|---|---|---|---|---|

| 140 | 5-1/2 | 136 | 92 | 210 | 14~43.1 |

| 178 | 7 | 171 | 135 | 247 | 23~38 |

| 194 | 7-5/8 | 185 | 145 | 247 | 26.4~47.1 |

| 219 | 8-5/8 | 210 | 170 | 253 | 32~49 |

| 245 | 9-5/8 | 235 | 197 | 255 | 32~75.6 |

| 340 | 13-3/8 | 332 | 276 | 343 | 48~72 |

| 40 | 16 | 403 | 338 | 451 | 65~109 |

| 473/508 | 18-5/8 / 20 | 500 | 380 | 495 | 94~133 |

drill pipe self-lock plug cementing tool: what is Difference from Other Types?

| Plug Type | Deployment String | Receiving Equipment | Primary Advantage |

|---|---|---|---|

| Conventional Top/Bottom Plug | Entire Casing String | Conventional Float Collar/Shoe | Separates fluids and wipes the entire casing string. |

| Non-Rotating Top/Bottom Plug | Entire Casing String | Non-Rotating Float Collar/Shoe | Prevents spinning during drill-out to save rig time. |

| Drill Pipe Self-Lock Plug | Drill Pipe or Tubing String | Stab-in/Latch-in Float Collar or Liner Wiper Plug Receptacle | Enables cementing of liners or cementing through small strings. |

Get Quotation

Drill Pipe Self-Lock Rubber Plug Cementing Tool

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

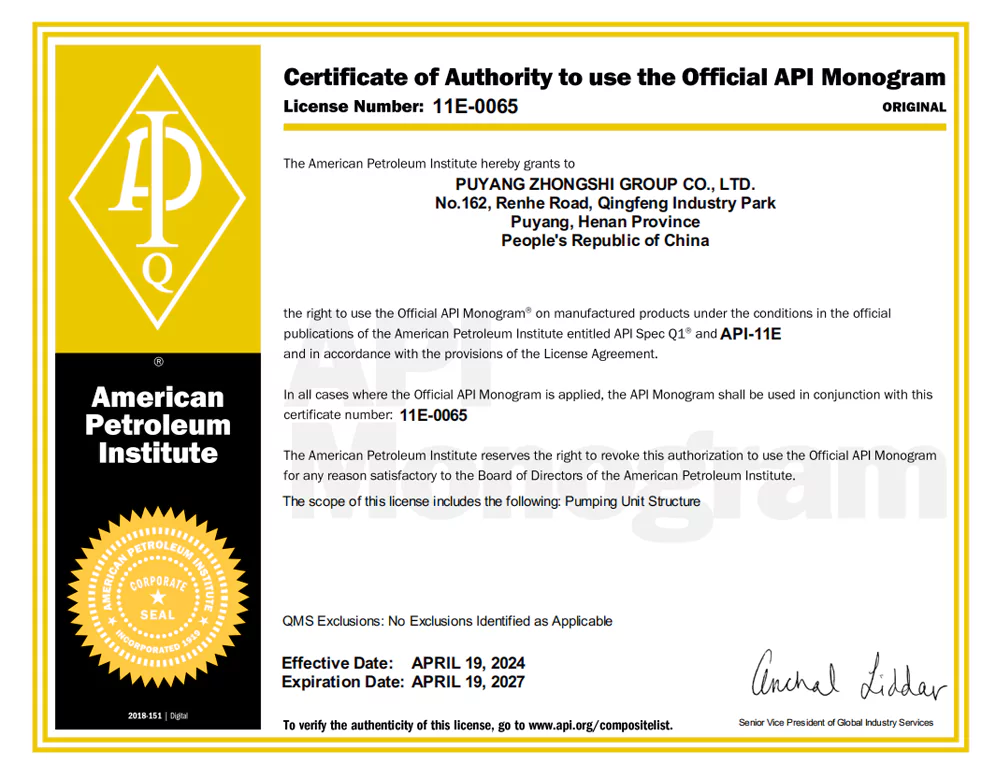

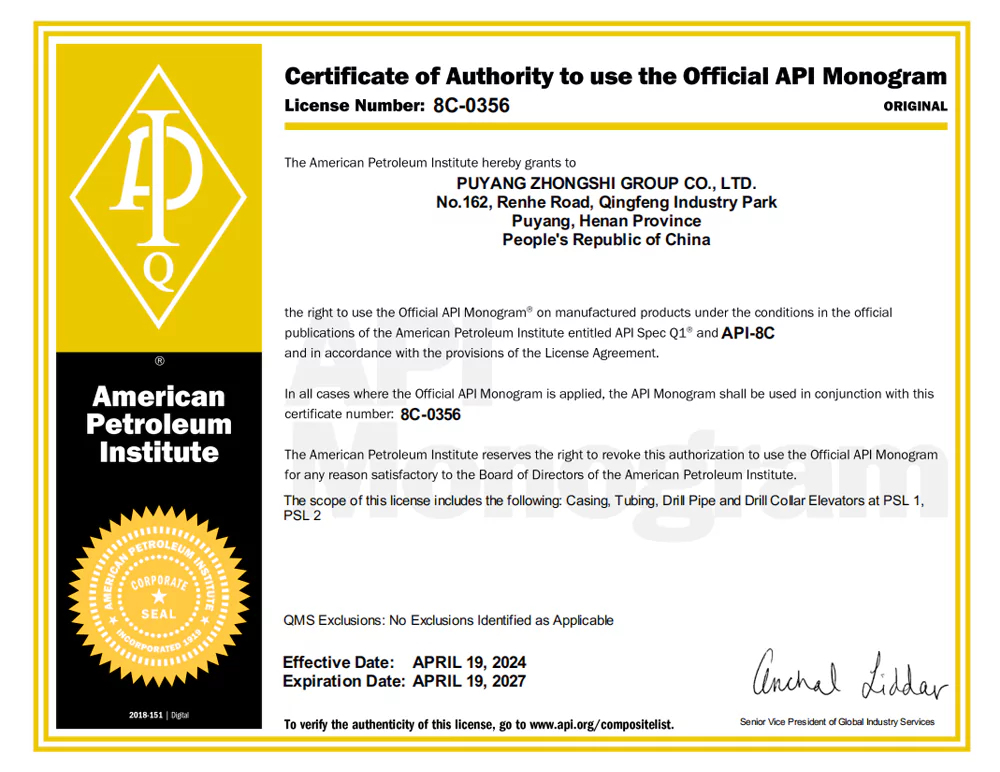

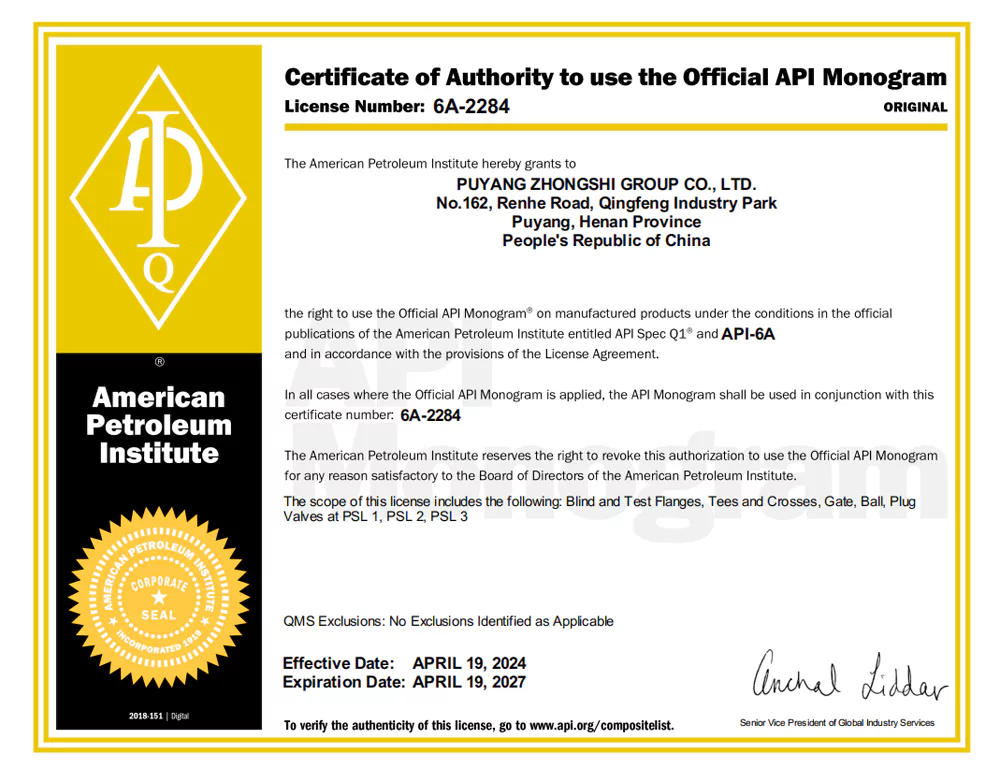

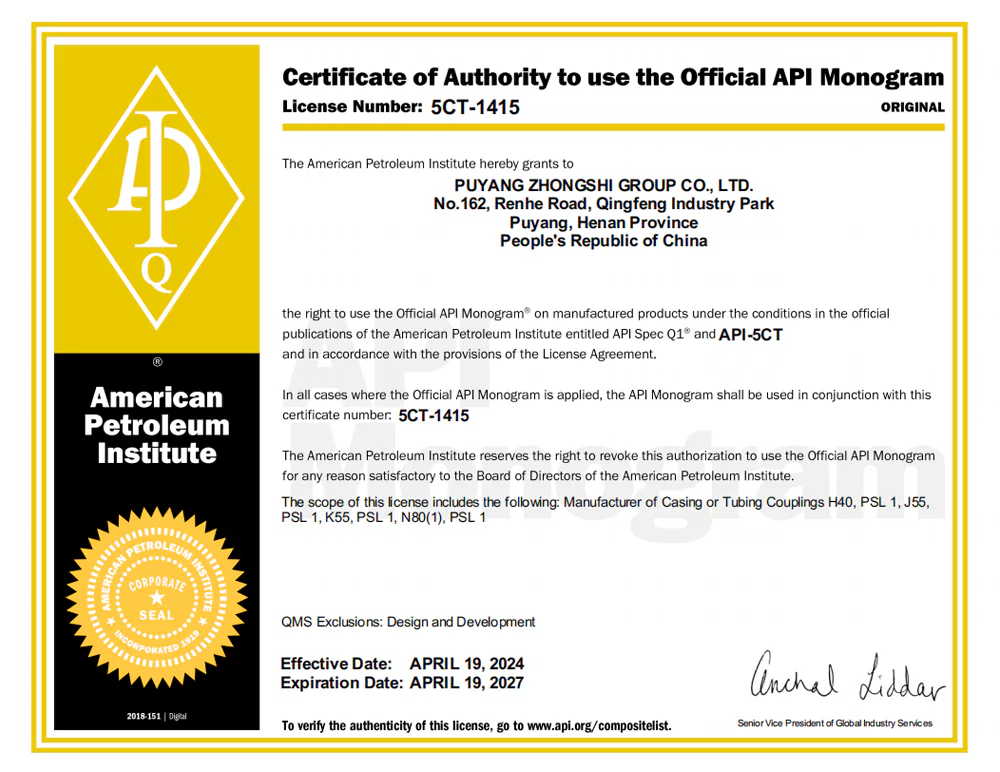

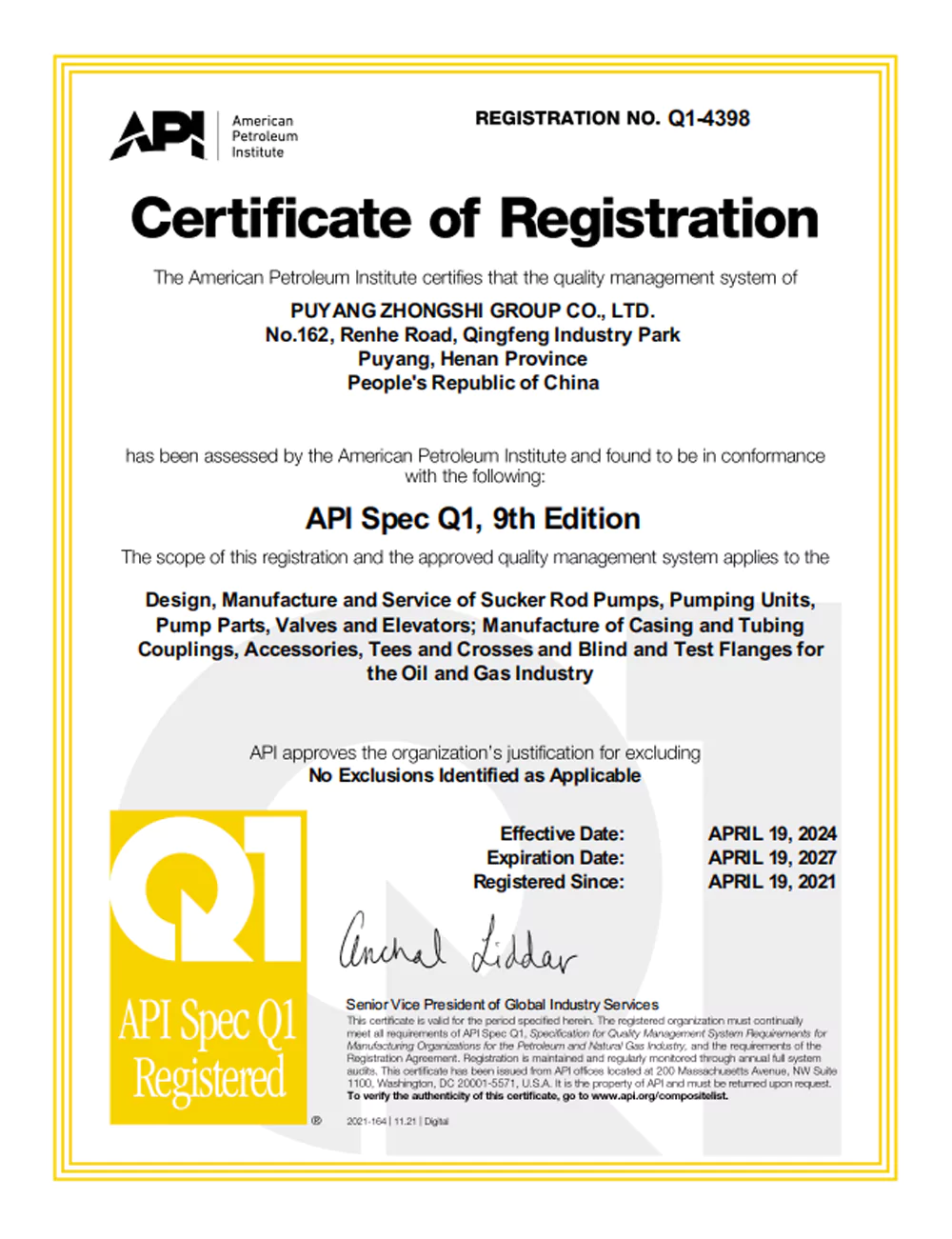

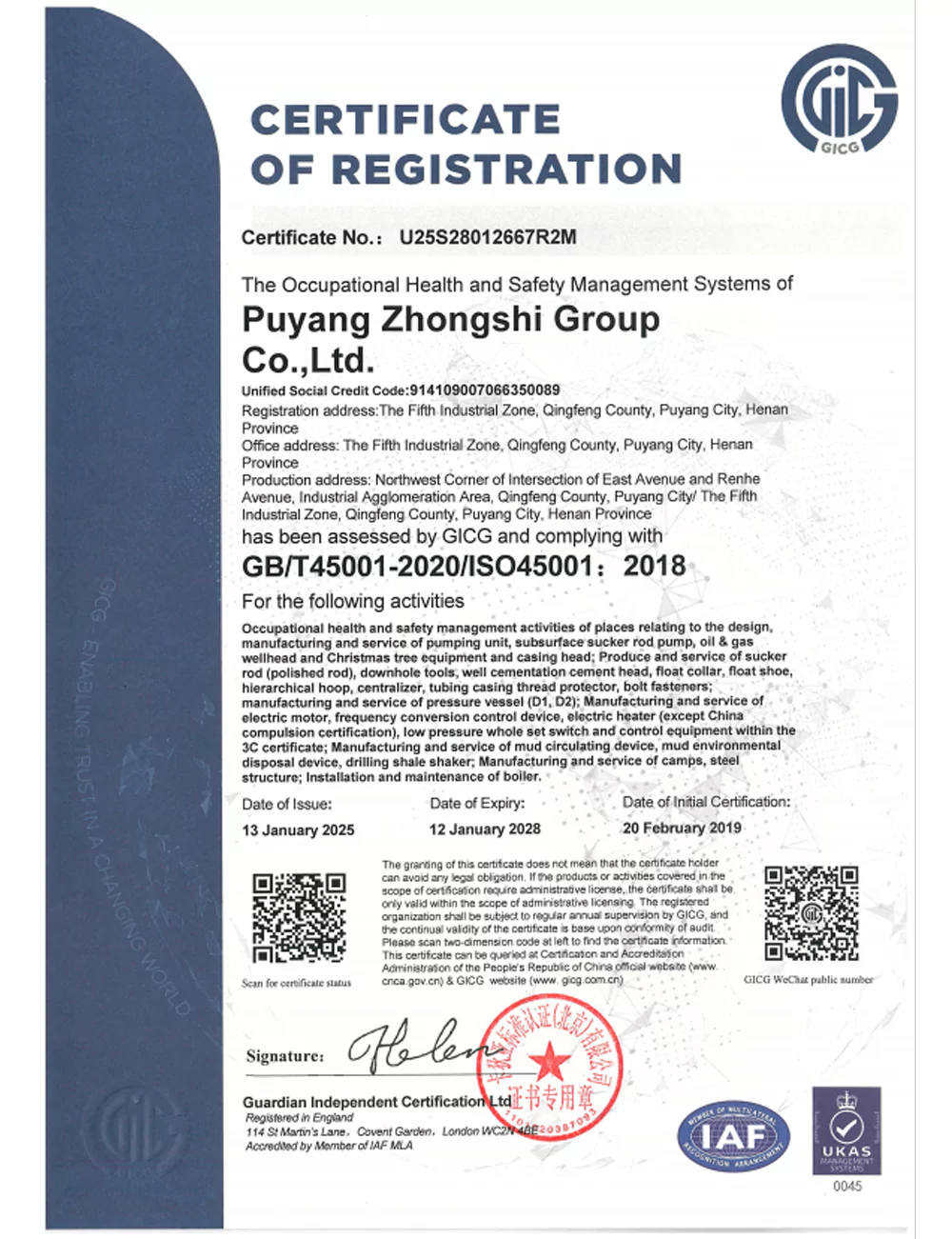

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.