Casing Top Drive Rotating Cement Head Oilfield

The Top Drive Rotating Cement Head Oilfield Tool is an advanced surface wellhead component specifically designed to connect directly to the rig’s Top Drive System (TDS). It integrates the primary functions of a cementing head with pipe rotation and extremely high load-bearing capacity. The Top Drive Rotating Cement Head Oilfield Tool is the ultimate tool for overcoming the most significant challenges in complex and long-wellbore drilling operations. Choose Puyang Zhongshi Group Co Ltd to be your reliable partner!

what is a top drive rotating cement head oilfield tool?

The top drive rotating cement head oilfield tool (TDCH) is an advanced surface wellhead component specifically designed to connect directly to the rig’s Top Drive System.

It integrates the primary functions of a cementing head (pumping fluids and launching plugs) with pipe rotation and extremely high load-bearing capacity.

core functions of top drive rotating cement head oilfield tool

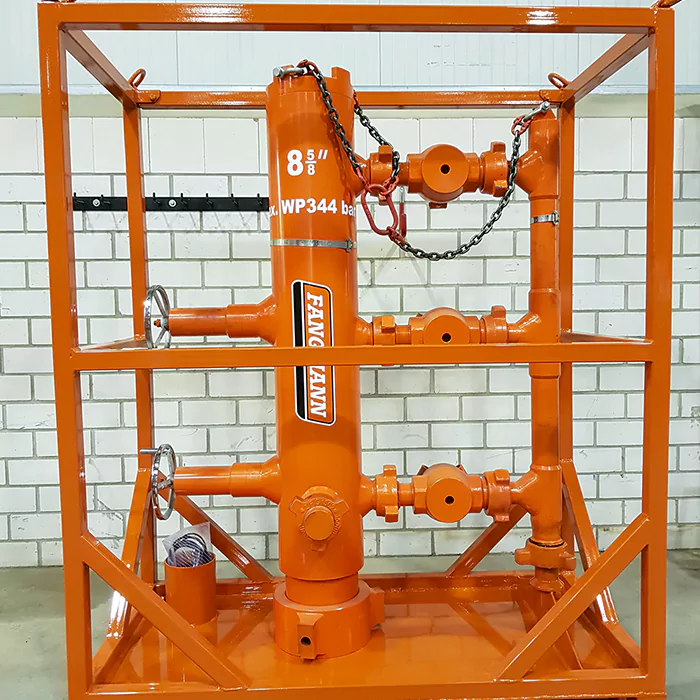

Direct Top Drive Integration: It connects directly to the bottom of the top drive, allowing it to move and rotate with the top drive system while simultaneously supporting the massive tensile load from a heavy casing string.

Enables Rotating Cementing: The top drive rotating cement head oilfield tool features a high-performance, integrated swivel that allows the rig to continuously rotate the pipe string (casing or drill pipe running string) without interrupting the pumping operation.

High-Load Design: The structure is engineered to be extremely robust, boasting high tensile, torque, and pressure ratings to safely handle the combined stresses of high-pressure pumping and the weight of deep, long pipe strings.

Top Drive Rotating cement head VS Other Types

| Top Drive Rotating Cement Head (TDCH) | Basic Rotating Cement Head (RCH) | Standard Casing Cementing Head (CCH) | |

|---|---|---|---|

| Rotation | Integrated swivel; high-RPM, designed for long-duration rotation. | Integrated swivel, but typically lower performance and load ratings than TDCH. | No rotation (Static head). |

| Connection | Connects directly to the Top Drive System. | Connects to the top of the pipe string, but typically not directly hooked to the Top Drive. | Connects to the top of the casing string. |

| Load Capacity | Extremely high (often over 3 million lbf tension, 10,000 psi pressure) to handle combined loads. | Lower capacity. | Lower capacity. |

| Operation | Often **Remote or Wireless operation** for plug release, minimizing manual intervention. | Mostly manual operation. | Manual operation. |

| Fluid Path | Designed with a bypass manifold to prevent cement from flowing through the top drive's sensitive internal components. | Typically lacks this specific design feature. | Direct line from pump unit into casing. |

top drive rotating cement head oilfield tool suitable for

The TDCH’s high-specification design makes it the ultimate tool for overcoming the most significant challenges in modern, complex drilling operations.

Complex and Ultra-Long Wellbores

Long Laterals and Deep Wells: The TDCH (Top Drive Cementing Head) is essential for extended-reach and ultra-deep wells. It enables continuous rotation during pumping to reduce friction, break up mud cake, prevent stuck pipe, and ensure the casing reaches target depth.

Liner Cementing: This tool is ideal for cementing liners. It safely manages the rotation of the drill pipe running string and accurately releases the balls/darts required to set the liner hanger downhole.

High-Risk and High-Load Operations

Heavy Casing Strings: Used for running and cementing extremely heavy pipe strings (common in deepwater or ultra-deep onshore wells), where its high tensile ratings ensure operational safety.

Increased Safety: The remote or wireless plug-releasing capability eliminates the need for personnel to operate valves at heights near the top drive, drastically improving overall rig safety.

data sheet of Double-Plug Cementing Head Drilling Pipe Use

| Size (mm) / (in) |

Pipe ID (mm) |

Length (mm) |

Working Pressure (Mpa) |

Plug Length Capacity (mm) |

Rotating Speed (r/min) |

Axial load (T) |

Weight (KG) |

Manifold Union |

Part No. |

|---|---|---|---|---|---|---|---|---|---|

| 178 7 |

178 | 2900 | 70 | 350 | 50 | 240 | 938 | 2" 1502 | DPCHTD1782150 |

| 245 95/8 |

245 | 3820 | 50 | 420 | 50 | 300 | 3000 | 2" 1502 | DPCHTD2452150 |

| 340 133/8 |

340 | 4300 | 35 | 420 | 50 | 300 | 5000 | 2" 1502 | DPCHTD3402150 |

Get Quotation

Casing Top Drive Rotating Cement Head Oilfield

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

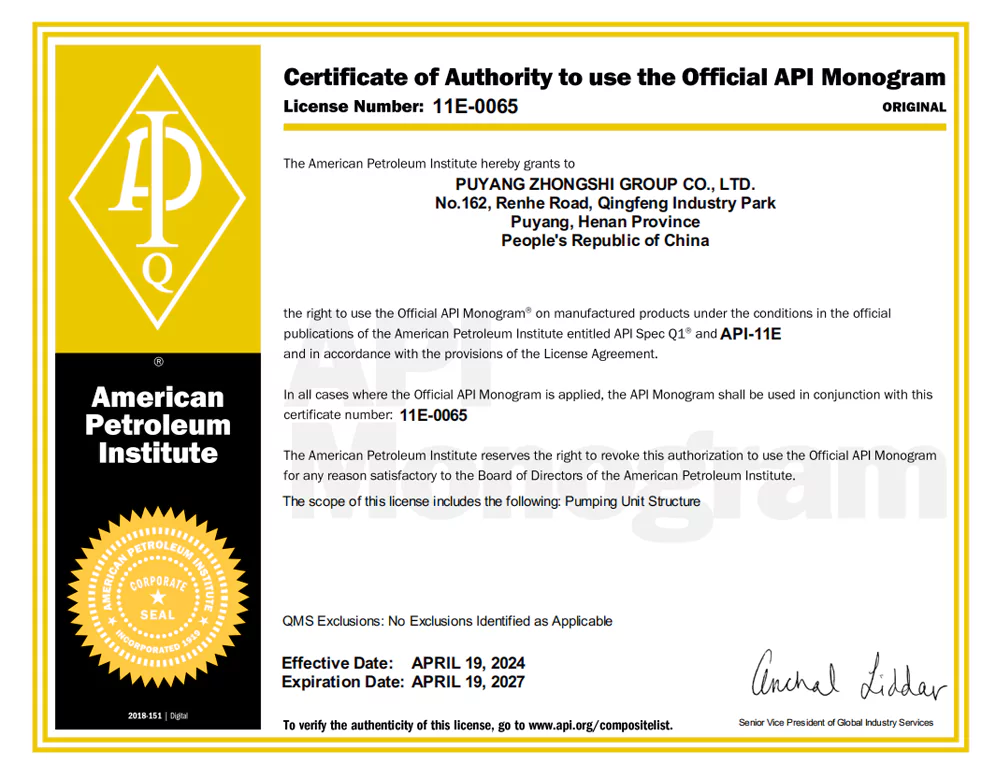

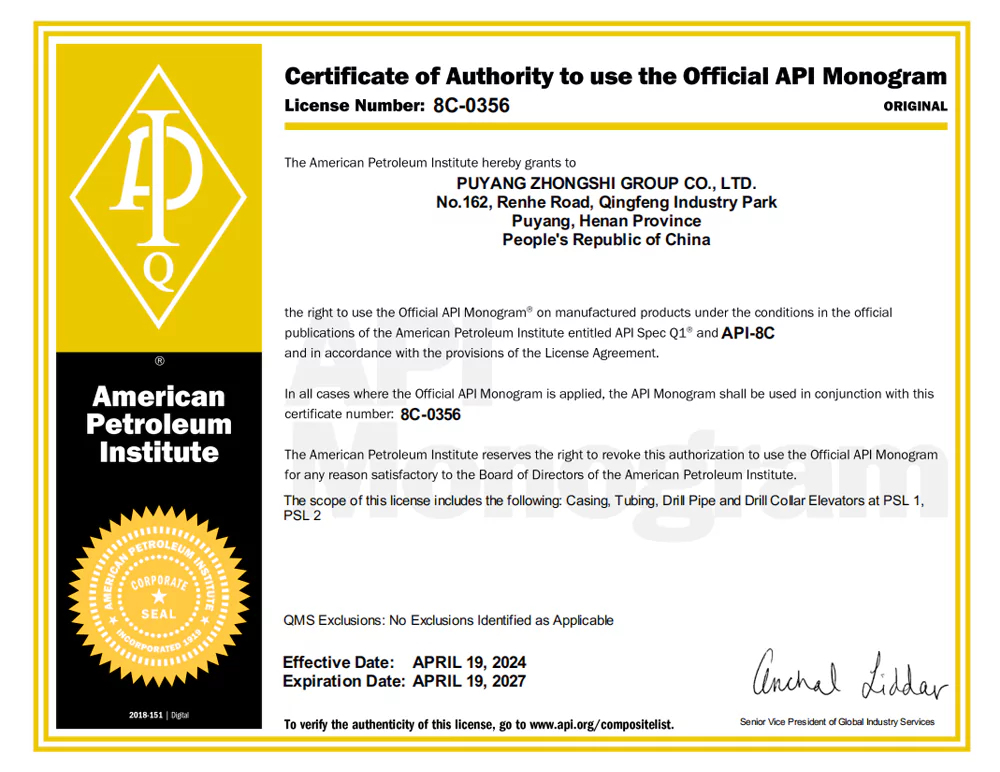

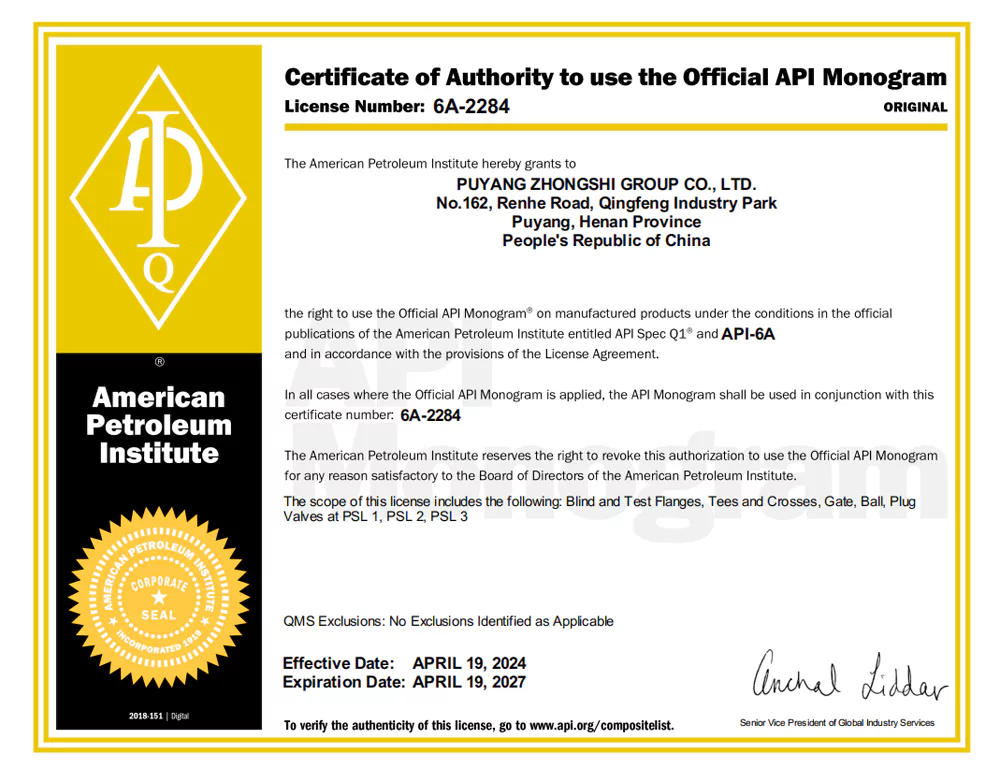

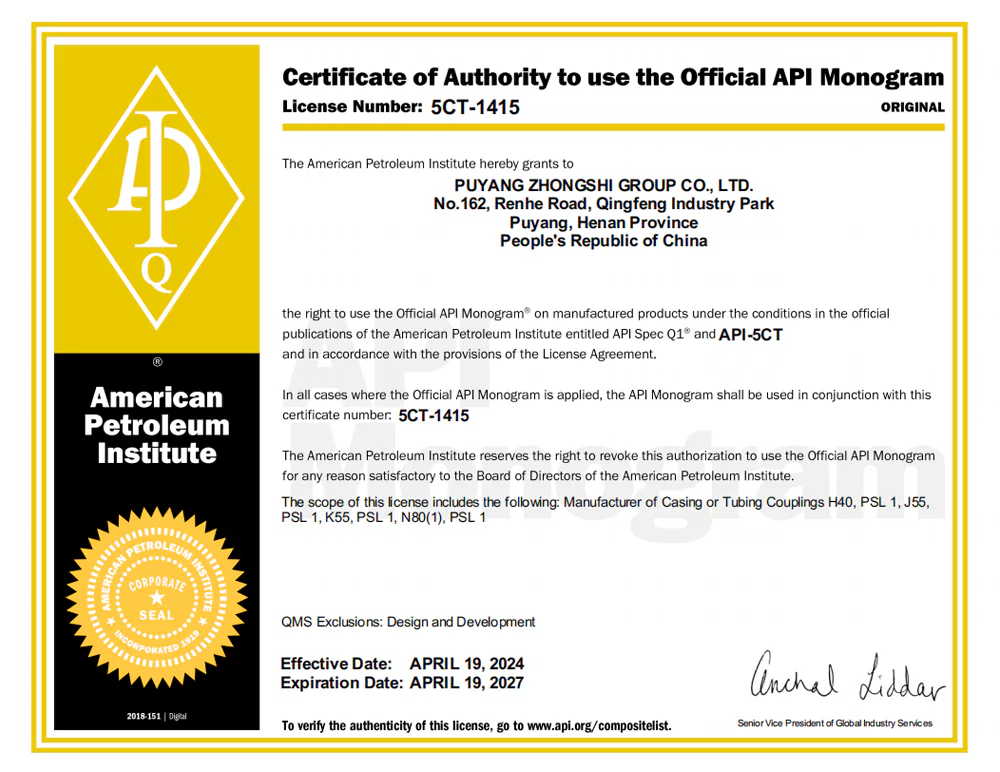

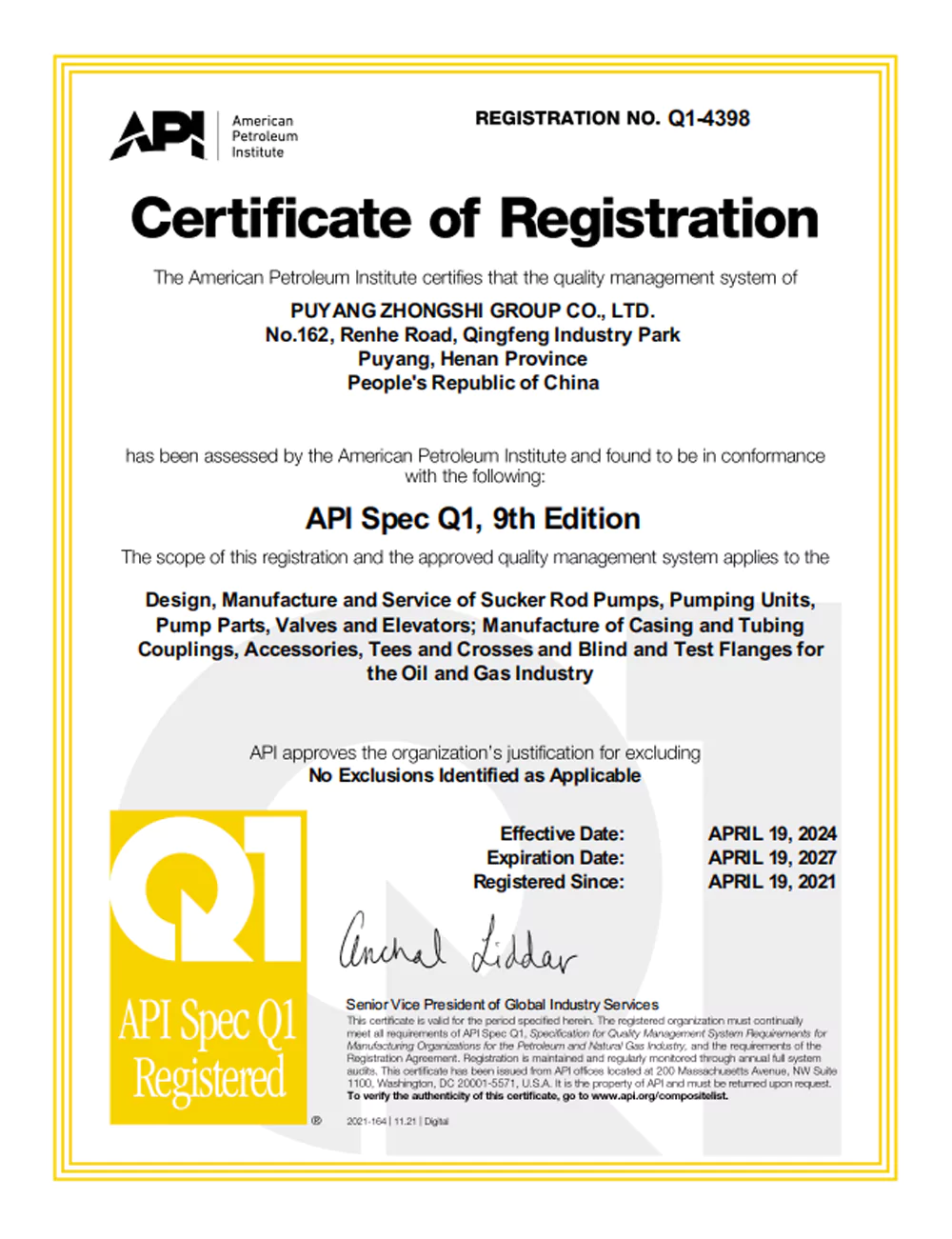

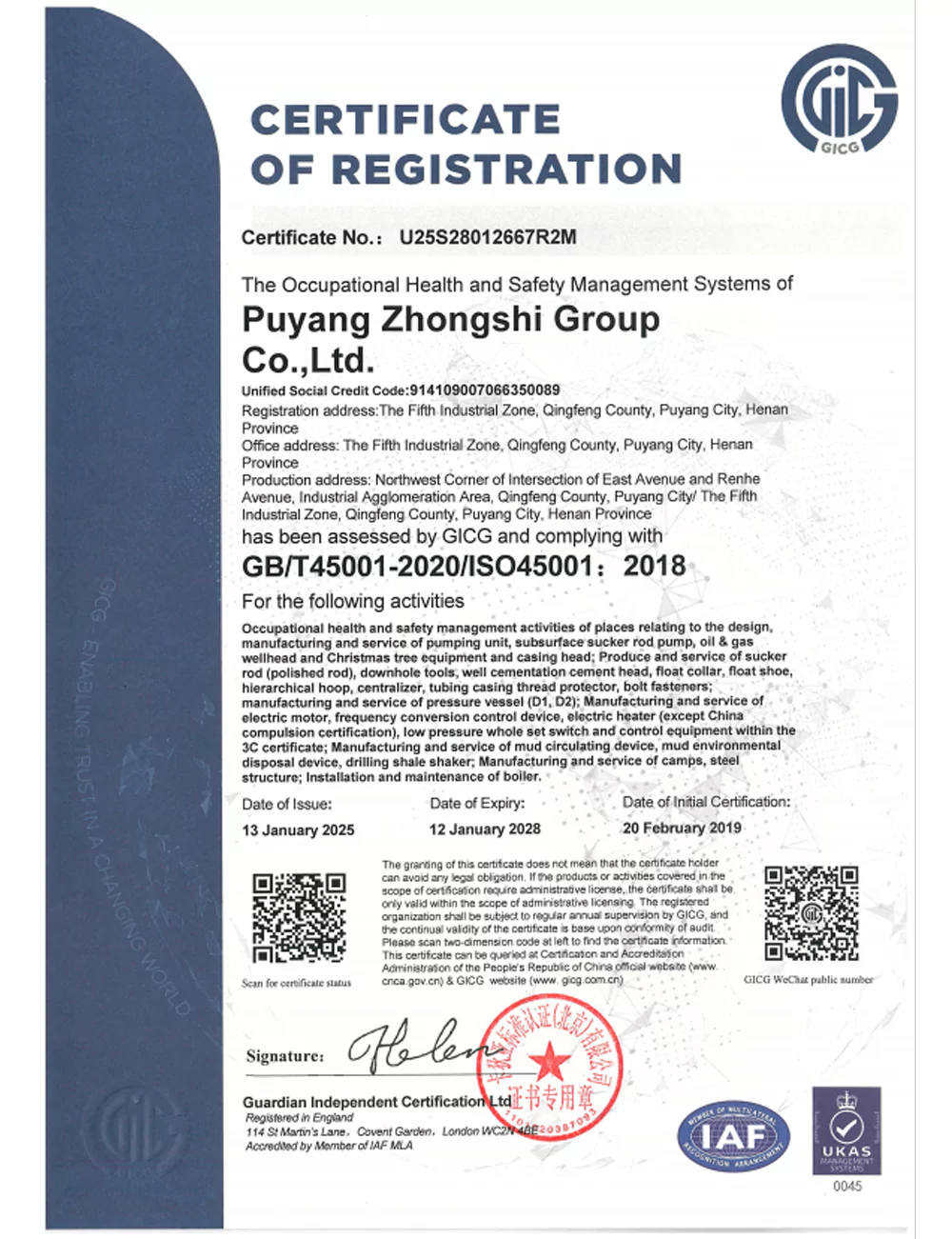

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.