hot selling cement head products

what is cement head?

Cement head is widely used in oil and gas field for connecting the cement pumping lines to the top of the casing string. It allows for the controlled pumping of cement slurry and the launching of cementing plugs into the wellbore.

Common Cement Head Types

Single Plug Cement Head

This is the simplest type of cement head. It's designed to hold and launch only one cementing plug, typically the top plug. It's used for cementing jobs where a bottom plug isn't required or has already been placed in the casing.

Double Plug Cement Head

This is the most common and widely used type in the industry. It can hold and release both a bottom plug and a top plug in a controlled, sequential manner. The bottom plug is launched first to separate the drilling fluid from the cement slurry, followed by the top plug, which separates the cement from the displacement fluid.

Clamp-Type Cement Head

This isn't a separate category but rather a connection style that can apply to either a single or double plug cement head. Instead of a threaded connection, it uses a mechanical clamp to securely attach to the top of the casing. This method is often faster and more secure, particularly for large-diameter casing.

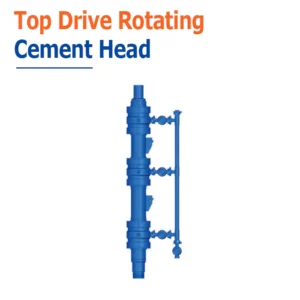

Rotating Cement Head

This specialized cement head is used when the casing string needs to be rotated during the cementing process to improve the cement bond. It has a swivel or bearing mechanism that allows the casing to turn while the cement head and pumping lines remain stationary. This prevents the lines from twisting.

Drill Pipe Cement Head

This is a unique type that connects to the top of a drill pipe, not the casing. It's used for specific cementing operations, such as setting cement plugs for well abandonment, squeeze cementing, or cementing through a smaller diameter pipe. It allows for the controlled placement of cement in a variety of downhole scenarios.

Liner Cement Head

.A liner cement head is used to perform cementing operations on a liner. The liner cement head connects to the top of the drill pipe, which is used to run the liner. This allows cement slurry and plugs to be pumped from the surface, through the drill pipe, and into the liner to secure it in the wellbore.