Non-Rotating Bottom & Top Plug Cementing Tool

What is Non-Rotating Bottom & Top Plug Cementing Tool ?

The Non-Rotating Bottom & Top Plug Cementing Tool uses a specialized design feature—typically a matching set of interlocking teeth or unique profile—on the core of both the top and bottom plugs, and the corresponding float equipment (Float Collar/Shoe).

When the plugs land, the interlocking profile on the bottom plug engages with the profile on the float collar. Crucially, when the top plug lands on the bottom plug, their matching profiles lock together, creating a rigid, non-spinning assembly at the bottom of the casing.

This mechanical locking feature is designed to eliminate rotational movement during the drill-out phase.

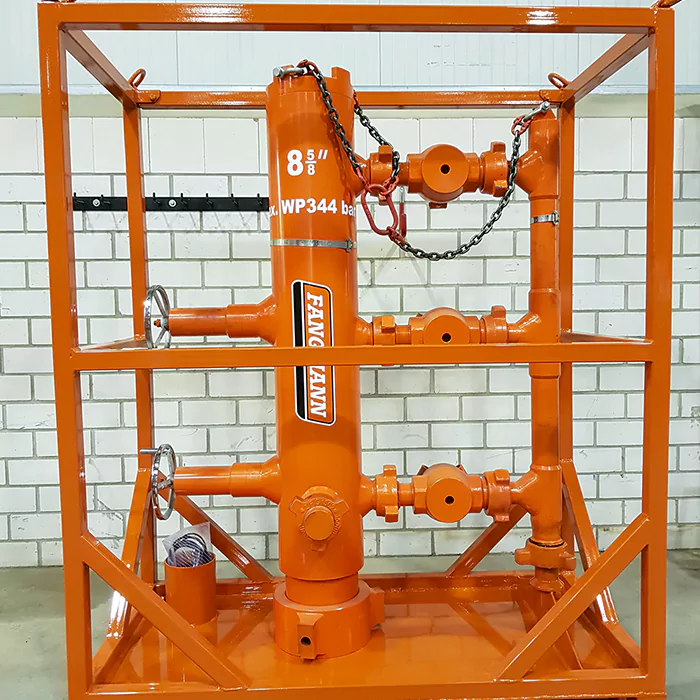

NR Bottom Plug Cementing Tool

NR Bottom Plug Cementing plug is usually Red or Orange. It launched before the cement. Separates drilling mud from the lead edge of the cement slurry and wipes the casing ID.. It has a rupture diaphragm/membrane that bursts open when seated, allowing the cement to flow through it and into the annulus.

NRTop Plug Cementing Tool

NR Top Plug Cementing plug is usually Black or Blue. It launched after the cement. Separates the cement slurry from the following displacement fluid (mud or water). It lands on the bottom plug, sealing the internal casing volume and creating a final pressure seal.

Once the plugs are bumped (landed) in the float equipment (float collar, float shoe) at the bottom of the casing, they seal the casing interior and are later drilled out.

Key advantages of Non-Rotating Bottom & Top Plug Cementing Tool

Significantly Reduced Drill-Out Time (Primary Advantage): By preventing the plugs from spinning (“acting as a bearing”) as they are contacted by the drill bit, the non-rotating plugs are drilled out much faster than conventional plugs. This saves valuable rig time and cost.

Optimized for PDC Bits: The non-rotating feature is particularly critical when using Polycrystalline Diamond Compact (PDC) drill bits, which are highly efficient but can quickly cause conventional plugs to spin, leading to excessive wear on the bit and delays in the operation.

Enhanced Integrity: The robust cores and secure locking mechanism often allow for higher casing pressure testing immediately following the cement job, which is important for confirming wellbore integrity.

PDC Drillable Materials: Like their conventional counterparts, NR plugs are typically constructed from PDC-drillable materials (phenolic resin, composite plastics) to further reduce drill-out time.

Non-Rotating Bottom & Top Plug Cementing Tool is suitable for

All High-Cost/High-Efficiency Operations: Any job where rig time is extremely expensive, making a faster drill-out a significant economic benefit.

Horizontal and Extended Reach Wells (ERD): In these complex wells, achieving efficient drill-out deep in the lateral section is critical, and the time saved by preventing plug rotation is substantial.

PDC Bit Usage: Essential whenever a PDC drill bit will be used to drill out the cement shoe track (float equipment and plugs).

data sheet of Non-Rotating Bottom & Top Plug Cementing Tool

| Size (mm) / (in) | OD (mm) | Body Diameter (mm) | Height (mm) | Casing Weight (IB/FT) | |

|---|---|---|---|---|---|

| 140 | 5-1/2 | 136 | 92 | 210 | 14~43.1 |

| 178 | 7 | 171 | 135 | 247 | 23~38 |

| 194 | 7-5/8 | 185 | 145 | 247 | 26.4~47.1 |

| 219 | 8-5/8 | 210 | 170 | 253 | 32~49 |

| 245 | 9-5/8 | 235 | 197 | 255 | 32~75.6 |

| 340 | 13-3/8 | 332 | 276 | 343 | 48~72 |

| 40 | 16 | 403 | 338 | 451 | 65~109 |

| 473/508 | 18-5/8 / 20 | 500 | 380 | 495 | 94~133 |

Cementing plugs: Conventional VS Non-Rotating

| Plug Type | Fixation Mechanism on Landing | Drill-Out Performance | Equipment Requirement |

|---|---|---|---|

| Conventional Cementing Plugs | Lands on a flat surface, relying on friction and plug compression for initial sealing. | Can easily spin beneath the drill bit, especially PDC bits, leading to slow, inefficient drilling and bit wear. | Requires matching Conventional Float Shoe/Collar. |

| Non-Rotating Cementing Plugs | Mechanically locks into a profiled NR Float Collar/Shoe using interlocking teeth or profiles. | Prevents spinning, enabling much faster drill-out with minimal rig time and reduced bit wear. | Requires matching Non-Rotating Float Collar/Shoe. |

Can i buy only the top cement plug?

Yes, it is absolutely no problem to purchase just the top cement plug individually!

While top and bottom cement plugs are typically supplied and used as a matched set for conventional primary cementing operations, there are several scenarios where only a top plug is required. These include the replacement of a lost or damaged component, or for specific job designs that call for a single-plug system. In such operations, the risk of slurry contamination from the fluids ahead is deemed negligible, and the primary objectives are to wipe the casing ID clean behind the slurry and to receive a definitive pressure indication upon landing. Furthermore, top plugs are frequently used alone in remedial operations, such as setting a balanced cement plug for well abandonment or sidetracking, where a bottom plug is not part of the procedure. We can readily supply top plugs as standalone items to accommodate these specific operational requirements.

Get Quotation

Non-Rotating Bottom & Top Plug Cementing Tool

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

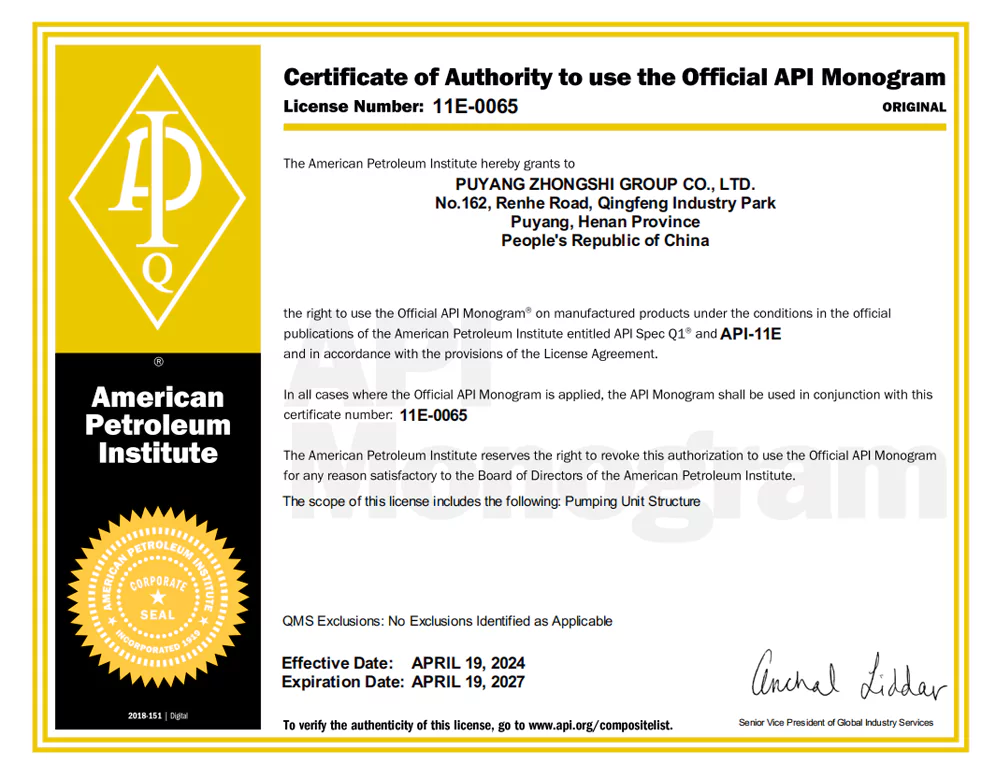

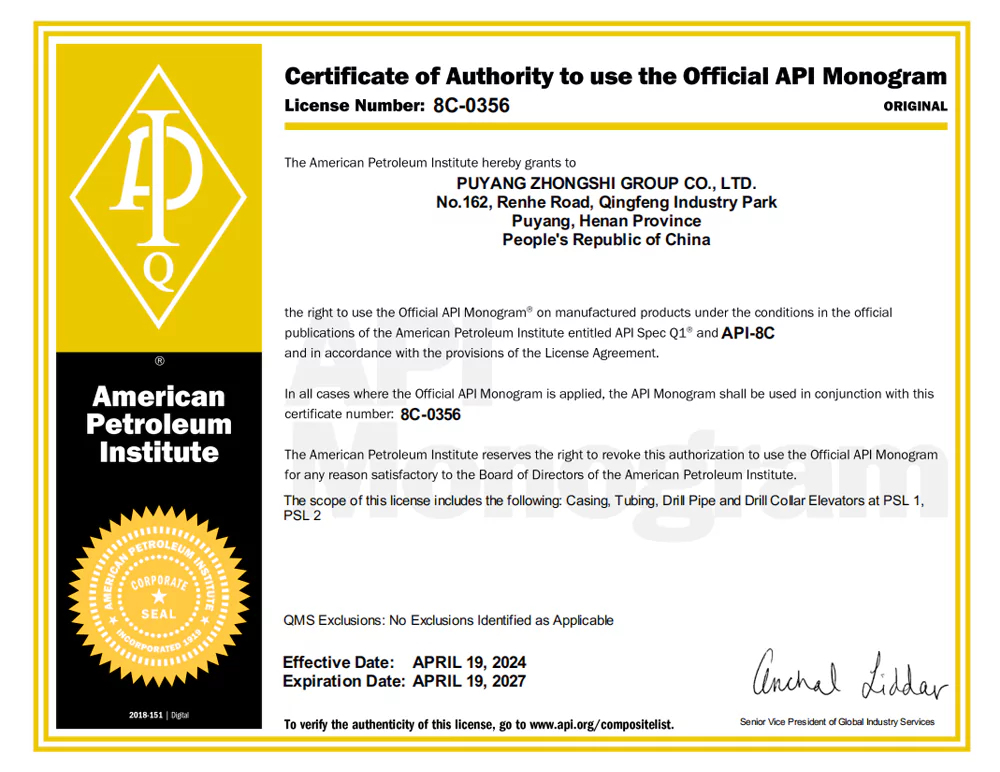

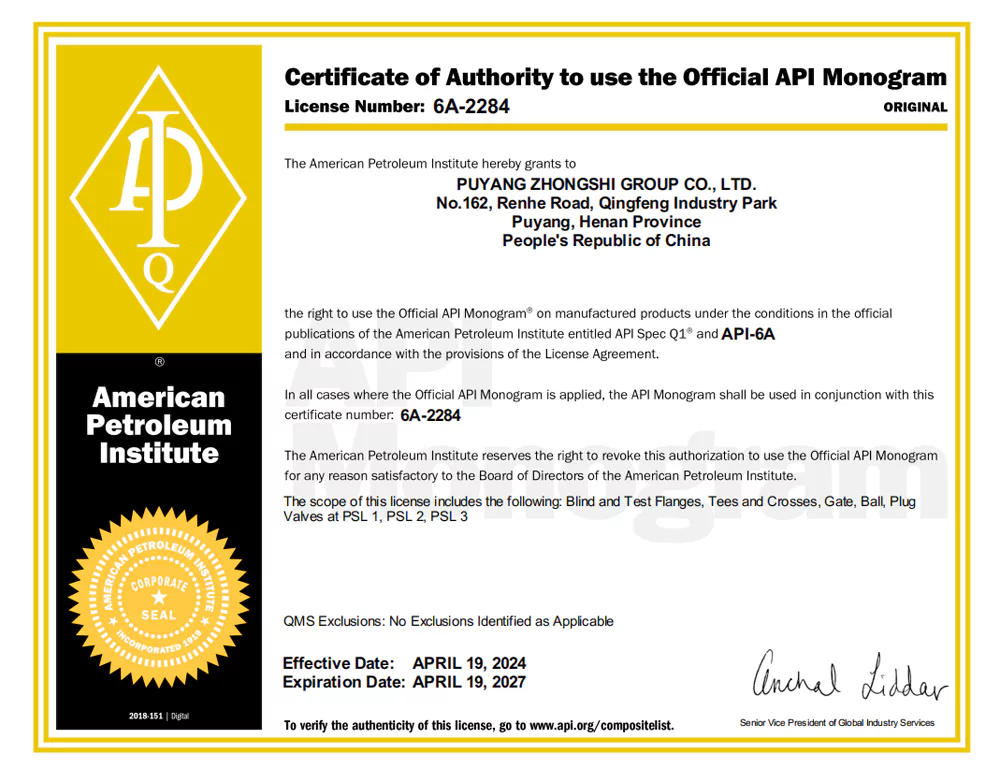

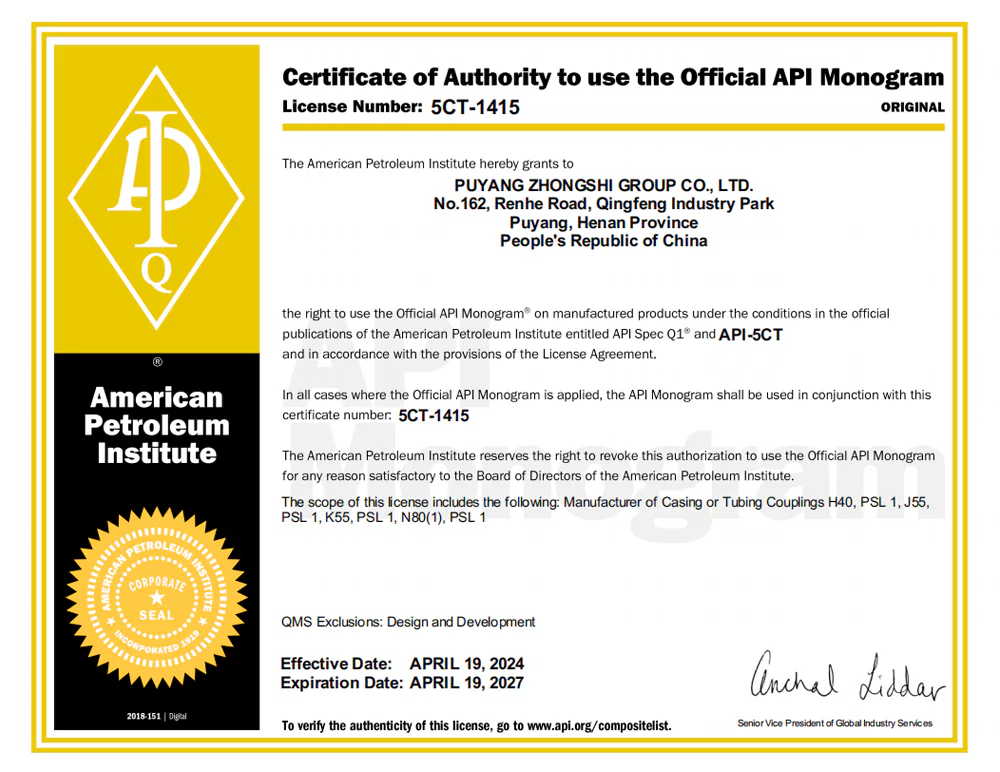

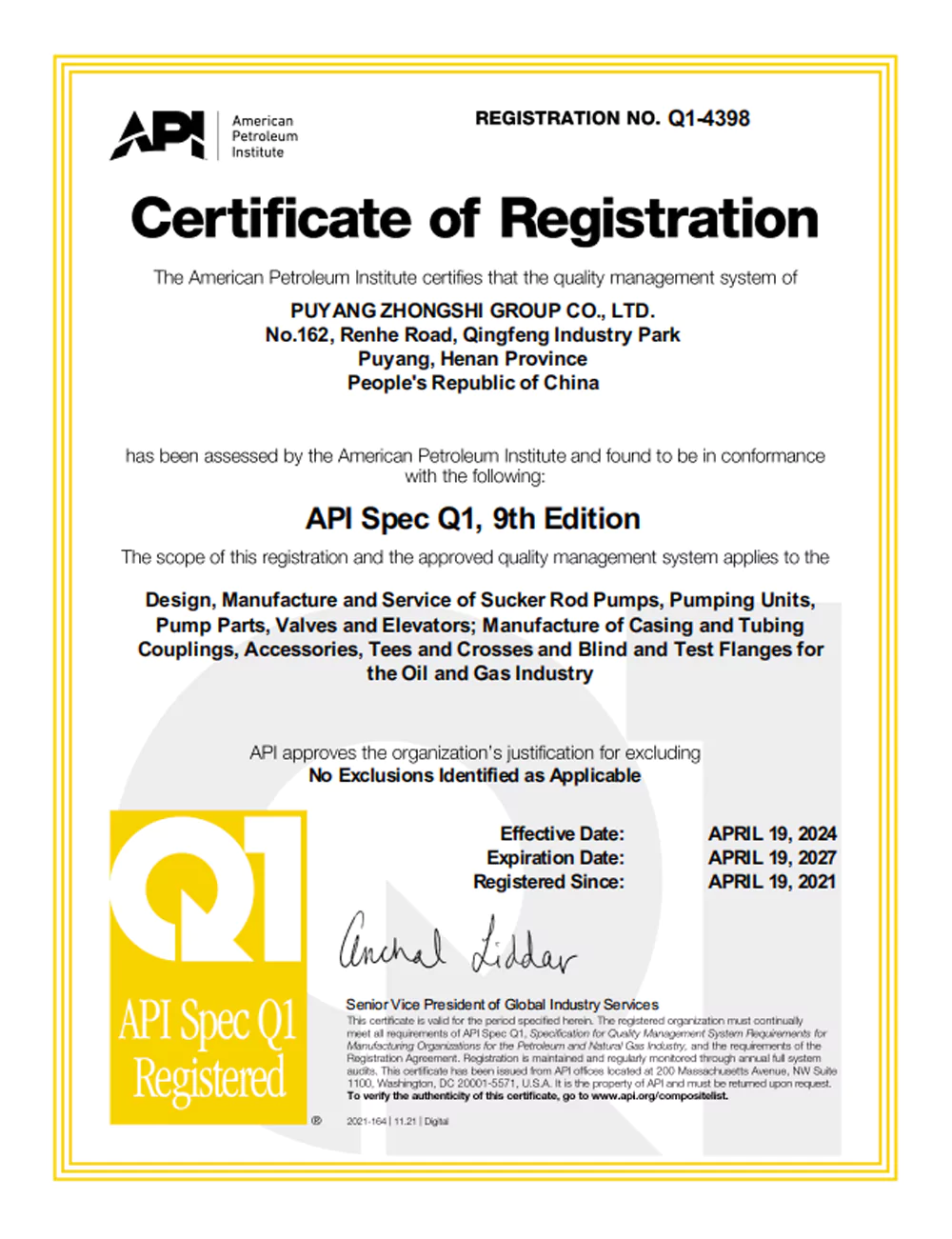

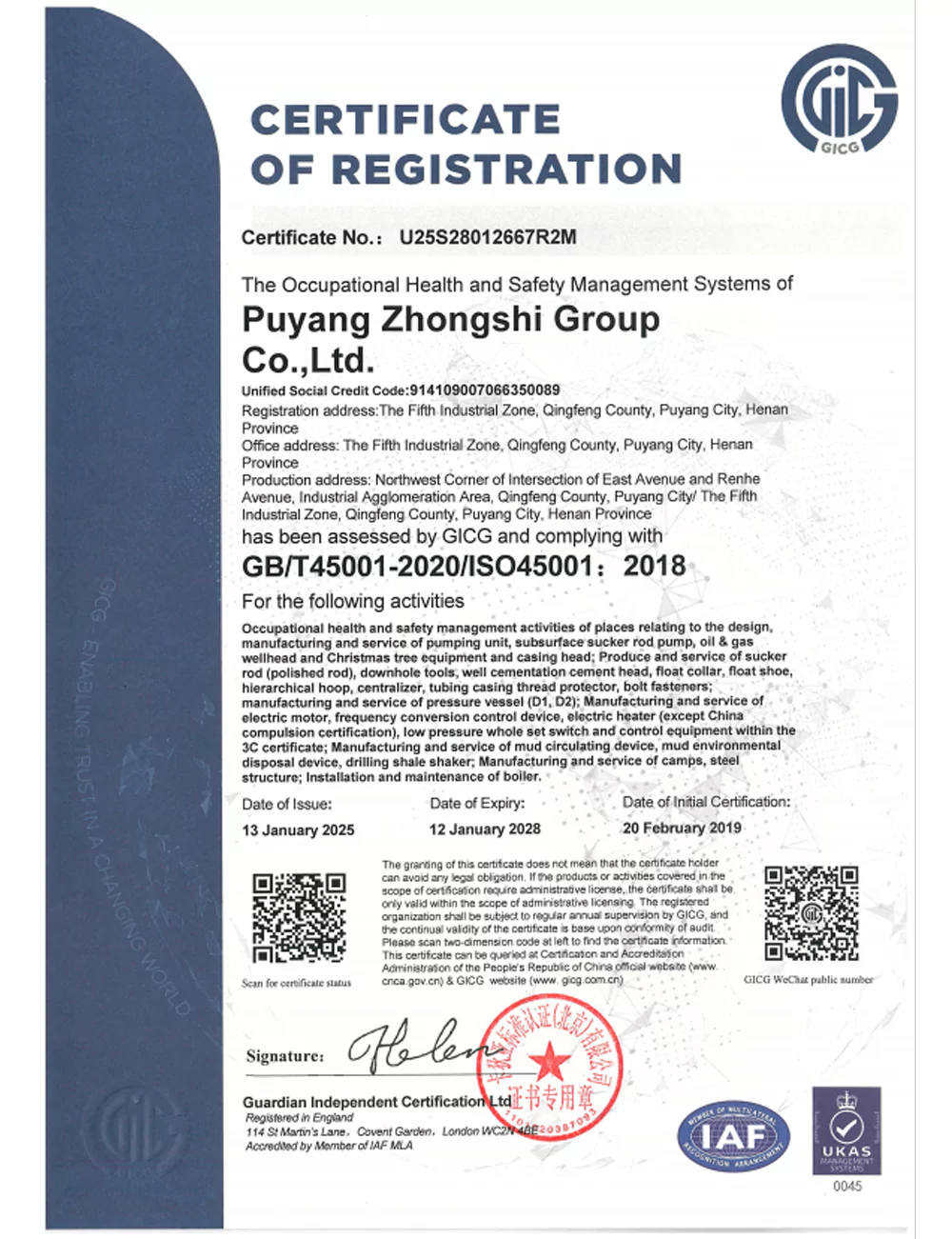

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.