Composite Centralizer

A composite centralizer is a type of rigid centralizer engineered using a combination of materials, typically fiberglass or carbon fiber reinforced with a polymer resin (such as epoxy, polyester, or proprietary engineering grade polymers). Puyang Zhongshi Group is the leading API certified factory and supplier for all types of casing centralizers including resin composite centralizer. Contact us consult for free!

What is a Composite Centralizer?

A Composite Centralizer is a non-metallic, rigid-body cementing tool made from advanced, high-strength composite materials. These typically involve reinforcing fibers (like fiberglass or carbon fiber) set within a durable polymer resin matrix (such as high-grade nylon, epoxy, or polyurethane).

Composite centralizer is engineered to combine the fixed-standoff stability of a rigid centralizer with the low-friction and corrosion-resistant properties of advanced materials. They feature external, often spiral-shaped, blades that wrap around the casing pipe to ensure it is centered in the wellbore annulus.

Key Advantages of Composite Centralizer

- Ultra-Low Friction & Drag: Thisis the primary advantage. The smooth surface of the composite material (sometimes combined with specialized coatings) provides a significantly lower coefficient of friction than steel. This reduces the drag force on the casing string, making it easier to run pipe to target depth.

- Superior Standoff and Cementing: The fixed, rigid blades ensure a guaranteed standoff ratio. When combined with spiral vanes, they induce swirling flow (turbulence) in the cement slurry, effectively removing drilling mud and ensuring a high-quality, continuous cement sheath for optimal zonal isolation.

- No Corrosion or Galvanic Risk: Since they contain no metal, they pose zero risk of galvanic corrosion between the centralizer and the steel casing. This is vital for long-term wellbore integrity in corrosive applications.

- High Strength and Wear Resistance: Unlike lower-grade plastic alternatives, these fiber-reinforced composites offer exceptional impact strength and abrasion resistance, allowing them to withstand the rigorous wear of long-distance trips down the wellbore.

- Safety and Handling: Their lightweight design improves manual handling on the rig floor, contributing to safer operations. They are also non-sparking, mitigating ignition risk in hazardous environments.

Composite Centralizer is suitable for

- Highly Deviated & Horizontal Wells: Essential for overcoming massive axial drag and torque in long laterals and extended-reach drilling (ERD), ensuring the casing string reaches total depth (TD).

- High-Temperature, High-Pressure (HTHP): Specialized high-grade resins are rated to withstand extreme temperatures (up to 350∘F or higher) and chemical degradation, maintaining integrity where traditional plastics fail.

- Sour Service & Corrosive Environments: Being non-metallic, they are chemically inert and immune to corrosion from H2S (Hydrogen Sulfide) and CO2 (Carbon Dioxide).

- Difficult Wellbore Geometries: The smooth, tapered body and robust structure allow the centralizer to pass through tight spots, washouts, and zones with high dogleg severity (DLS) without getting damaged or stuck.

- Casing/Liner Rotation: Their ultra-low friction coefficient allows for smooth casing rotation during cementing, which is critical for achieving optimal mud displacement.

data sheet of Composite Centralizer

| Size (in) | OD (mm) |

ID (mm) |

Length (mm) |

Part No. | |

|---|---|---|---|---|---|

| ID | OD | ||||

| 5-1/2 | 8-1/2 | 210 | 145 | 250 | RE05120812 |

| 7 | 8-1/2 | 210 | 182 | 265 | RE07000812 |

| 9-5/8 | 12-1/4 | 303 | 248 | 265 | RE09581214 |

| 13-3/8 | 17-1/2 | 420 | 344 | 265 | RE13381712 |

Get Quotation

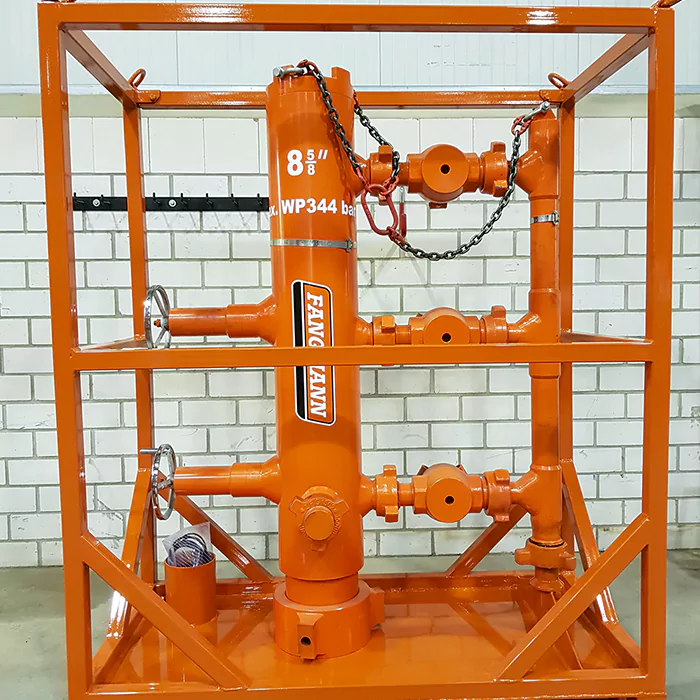

Composite Centralizer

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

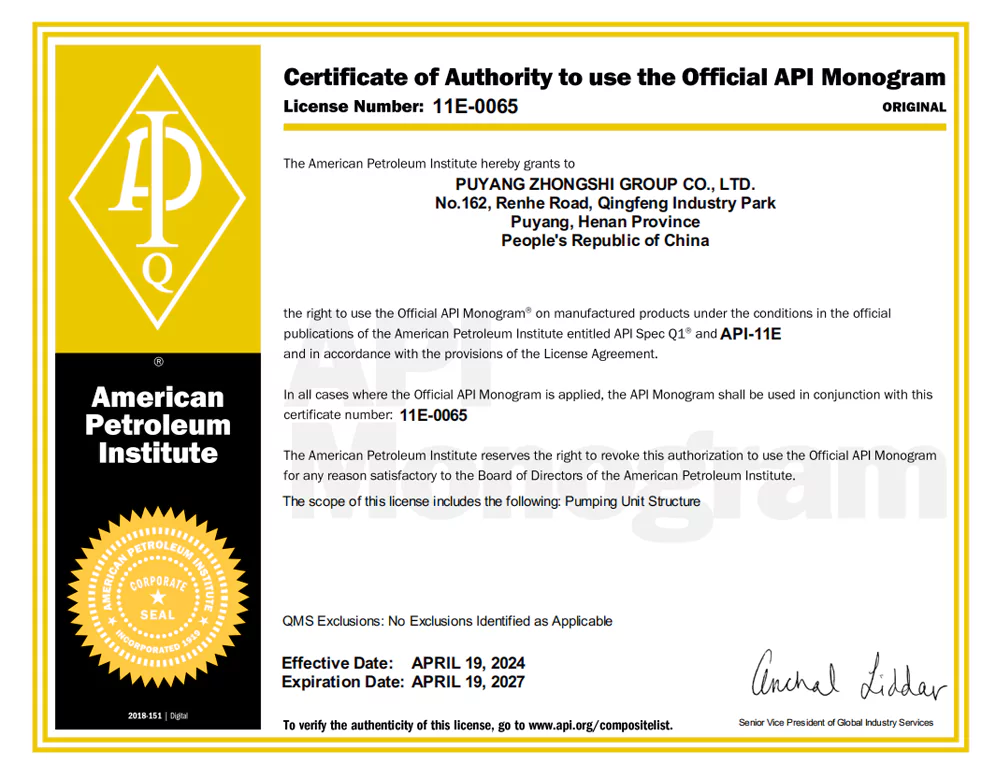

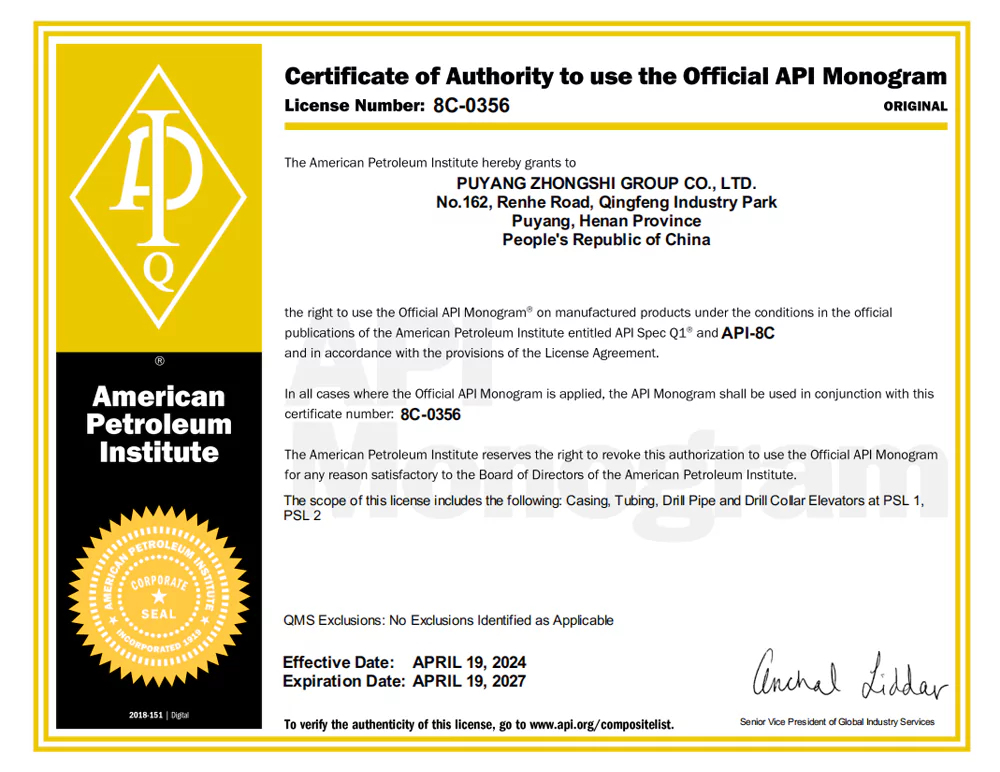

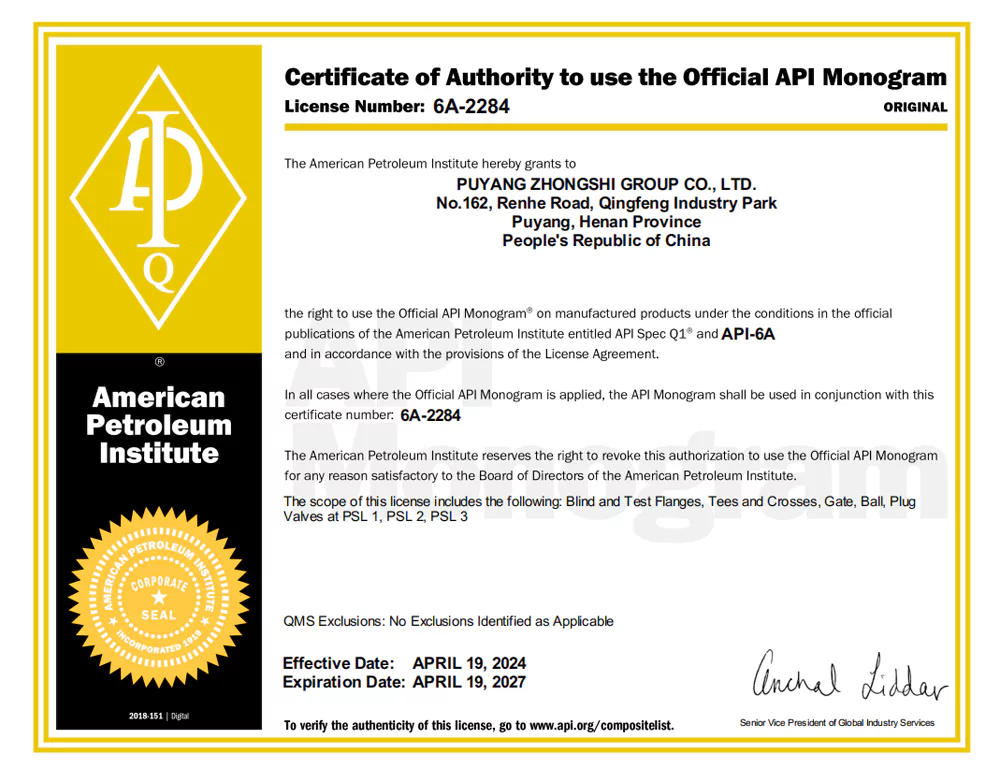

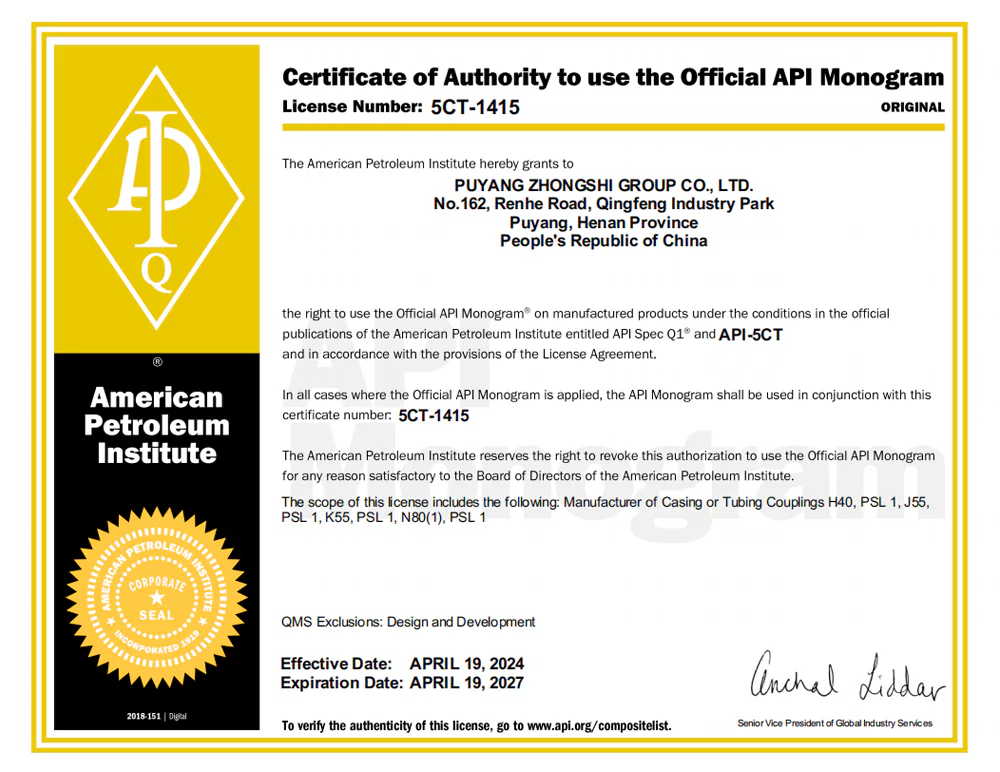

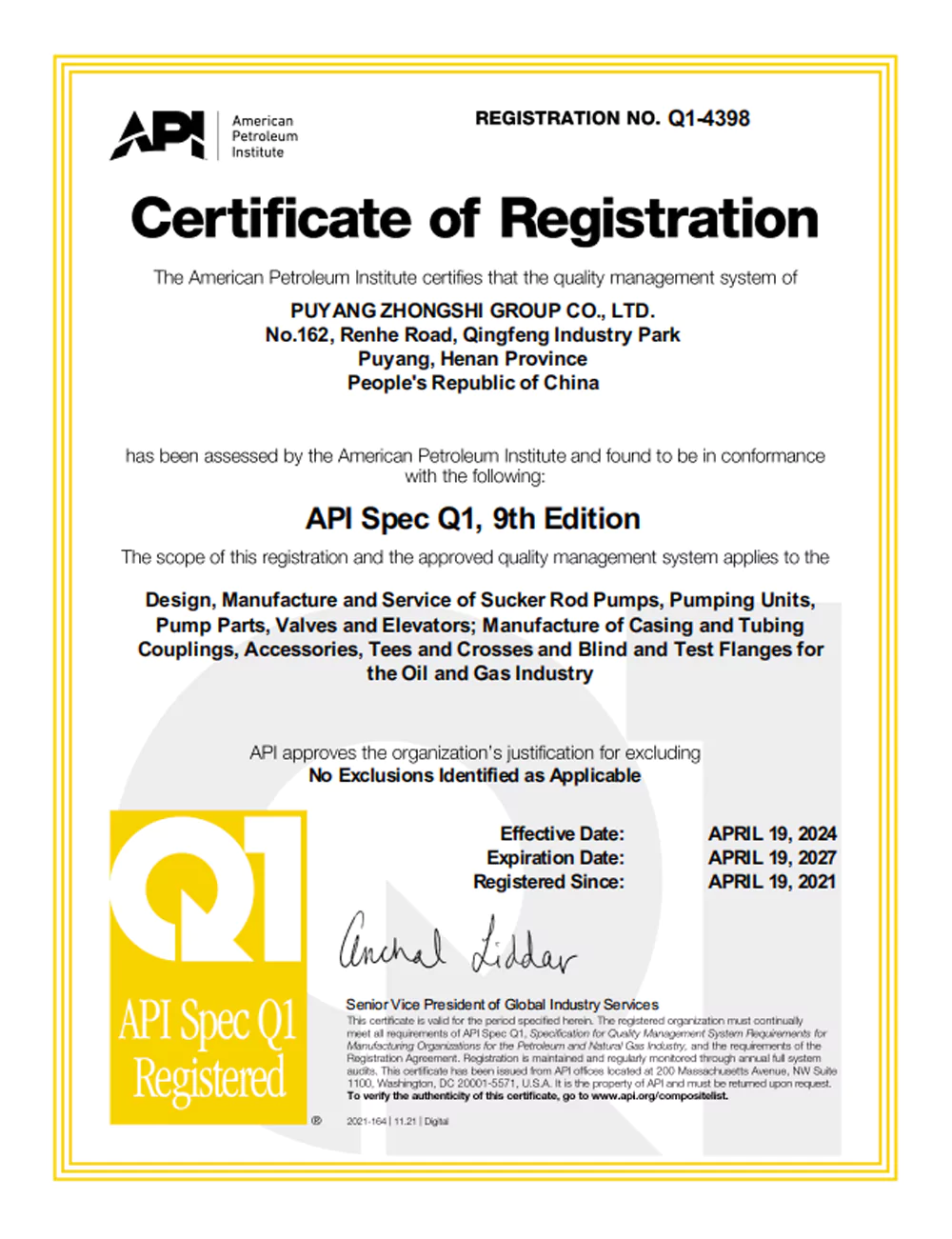

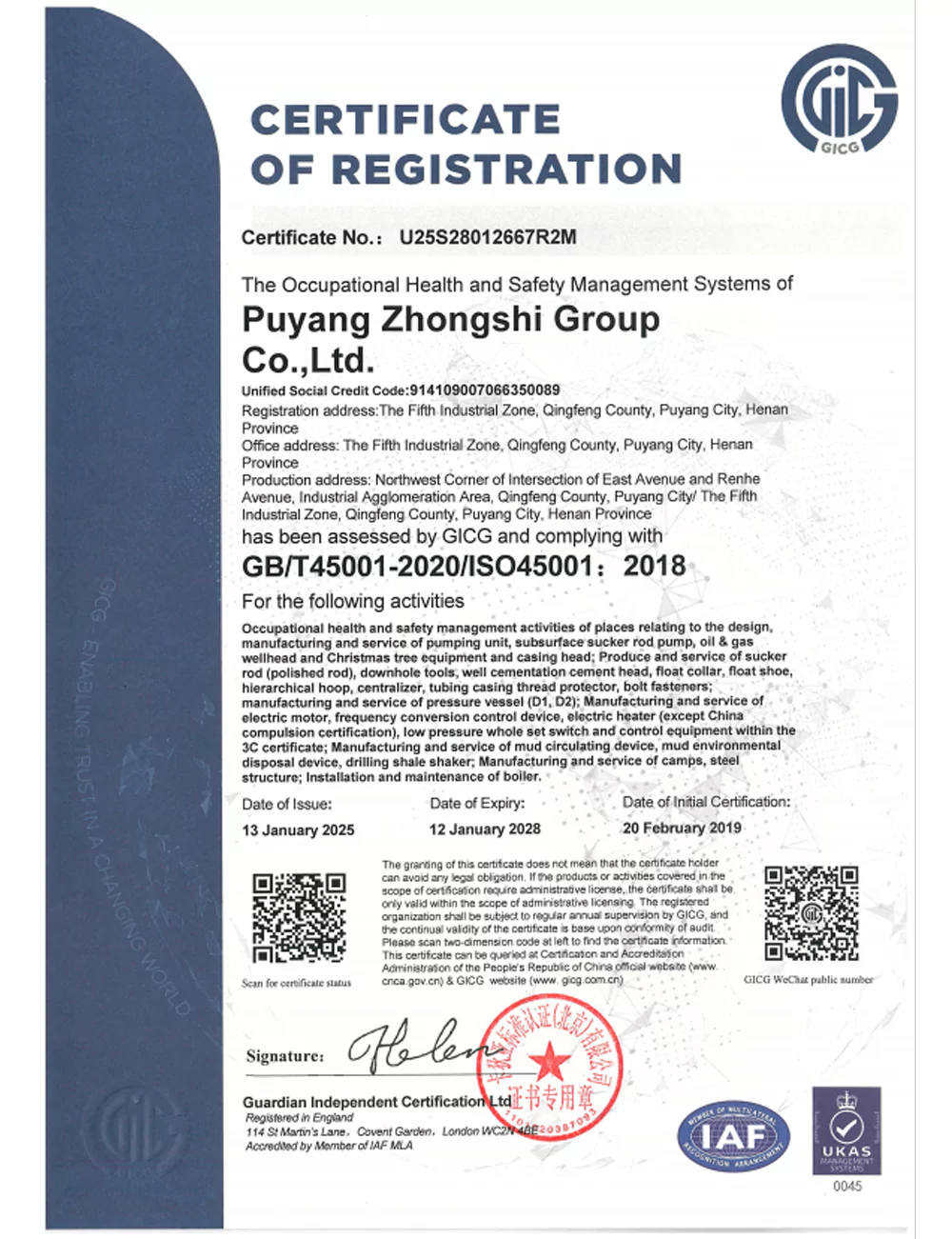

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.