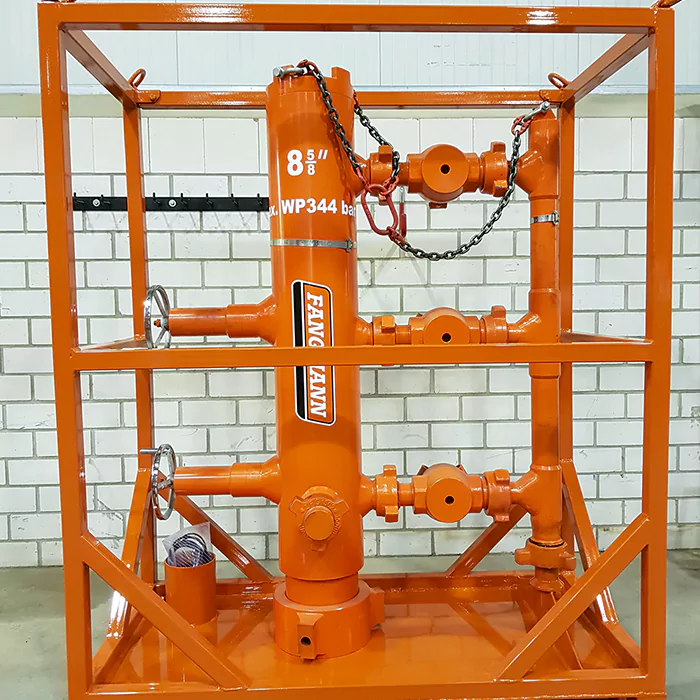

Roller Centralizer

A Roller Centralizer is a type of Solid Rigid Centralizer that features hardened, modified alloy steel rollers or wheels fixed along its blades or vanes. Puyang Zhongshi Group Co Ltd is the API certified golden supplier for all types of casing centralizers. Contact us to get the detailed quotation!

What is a Roller Centralizer?

A Roller Centralizer is a cementing tool integrated into the casing string whose primary function is to center the casing within the wellbore, ensuring a uniform annular space for optimal primary cementing. It consists of a rigid, solid body sleeve with straight or spiral blades, where the rollers are mounted on axles. The rollers convert the high sliding friction encountered in deviated wells into minimal rolling friction. This is critical for getting the casing or liner to total depth successfully.

Key Advantages of Roller Centralizer

- Low Drag & Torque: Converts Sliding Friction to Rolling Friction: This is the most critical benefit, enabling the casing or liner to be run to total depth (TD) with less applied force. It reduces the risk of the pipe getting stuck.

- Enhanced Cementing: Low torque allows for casing rotation and reciprocation during the cement placement, which promotes swirling flow (turbulence). This is vital for removing the mud cake and achieving superior cement bonding and zonal isolation.

- Reduced Wear: Minimizes wear on both the casing string and the wall of the open hole, preserving wellbore integrity.

- Anti-Sticking: The smaller contact area of the rollers, compared to a solid blade, reduces the risk of the casing becoming differentially stuck in permeable or under-pressured formations.

Roller Centralizer suitable for

The Roller Centralizer is specifically engineered for high-difficulty well construction where traditional centralizers face limitations due to friction and drag.

- Highly Deviated Wells: Suitable for wells with a steep inclination. Minimizes the frictional drag on the low side of the wellbore, ensuring casing reaches depth.

- Horizontal Wells: Suitable for Wells that run parallel to the formation for long distances (Extended-Reach Wells). Essential for overcoming massive axial and rotational drag and torque over thousands of feet.

- Liner Runs: When running a liner (a shorter casing string) that requires rotation and reciprocation. Low torque allows for effective rotation and reciprocation to enhance mud displacement before cementing.

- Tight Clearances: Operations where the annulus is narrow and minimizing drag is paramount to prevent sticking. Minimal contact area from the rollers reduces the risk of differential sticking.

data sheet of Roller Centralizer

| Size (in) | OD (mm) |

ID (mm) |

Length (mm) |

Weight (KG) |

Part No. | |

|---|---|---|---|---|---|---|

| ID | OD | |||||

| 9-5/8 | 12-1/4 | 305 | 248 | 300 | 22.8 | RC09581338 |

Get Quotation

Roller Centralizer

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

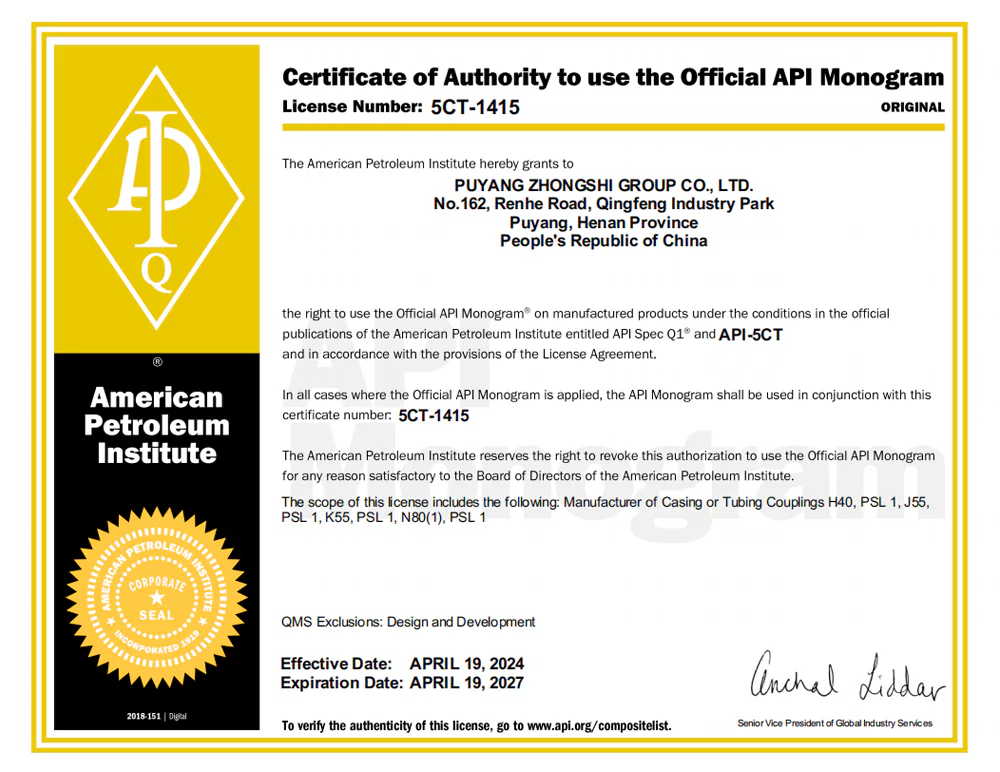

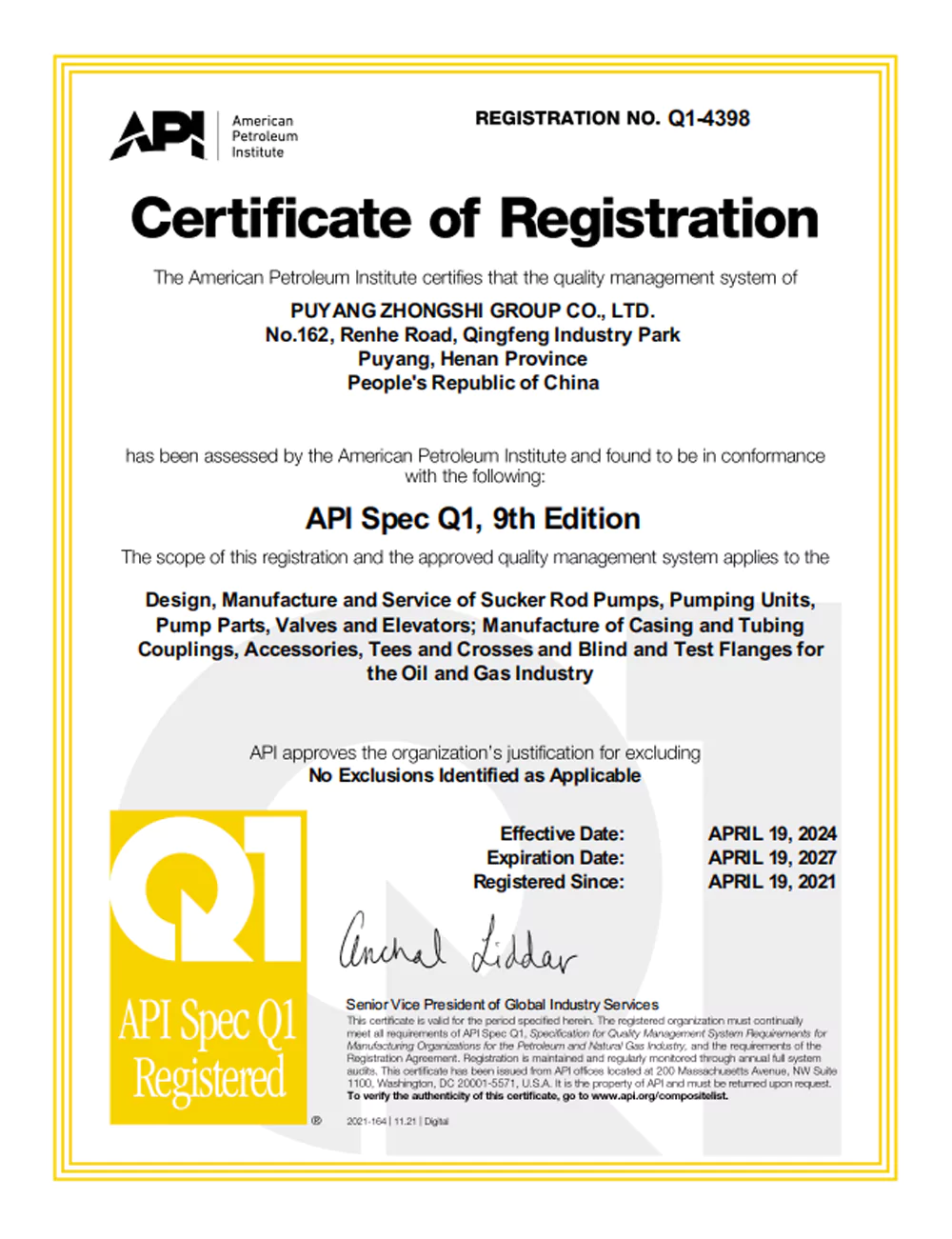

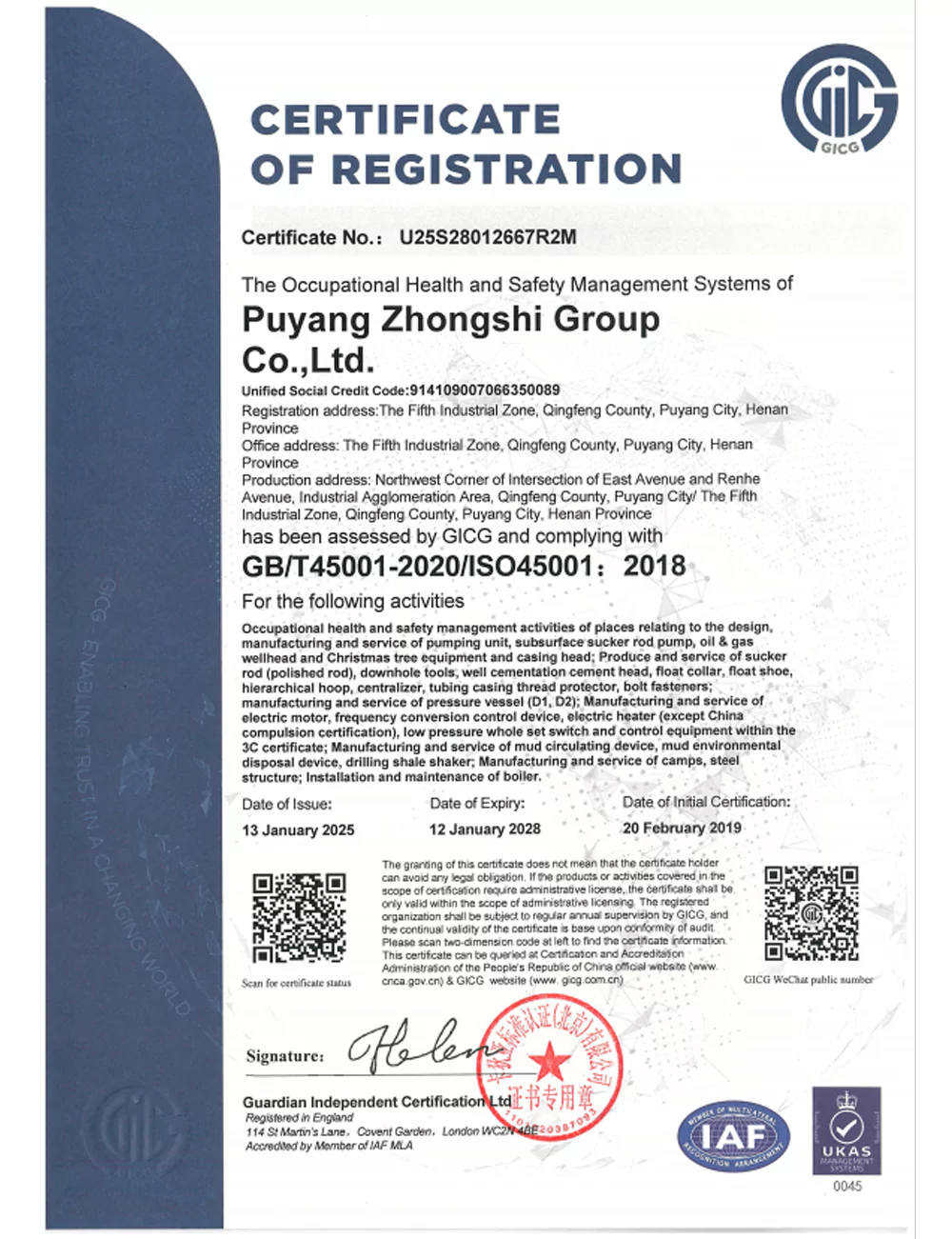

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.