Hinged Non Welded Bow Spring Centralizer

The Hinged Non-Welded Bow Spring Centralizer is one of the most widely used types of casing centralizers in the oil and gas industry. The non-welded design in this hinged bow spring centralizer ensures the full strength of the parent material is maintained. Choose Puyang Zhongshi Group Co Ltd Single Piece Centralizer for guaranteed wellbore cementing process!

what is a Hinged Non-Welded Bow Spring Centralizer?

The Hinged Non-Welded Bow Spring Centralizer consists of two primary end bands connected by flexible, curved bow springs. Crucially, it uses a non-welded assembly—meaning the bows are secured to the end bands mechanically, typically using crimping, interlocking tabs, or special locking pins.

It is a hinged (or latch-on) design, meaning the two halves are pinned together and can be fastened around the casing pipe at any point. You do not need to slide it over the casing connection/coupling.

The bow springs compress as the casing is run into the hole, and their inherent spring-back action (restorative force) pushes the casing away from the wellbore wall, centering it.

key features of Hinged Non-Welded Bow Spring Centralizer

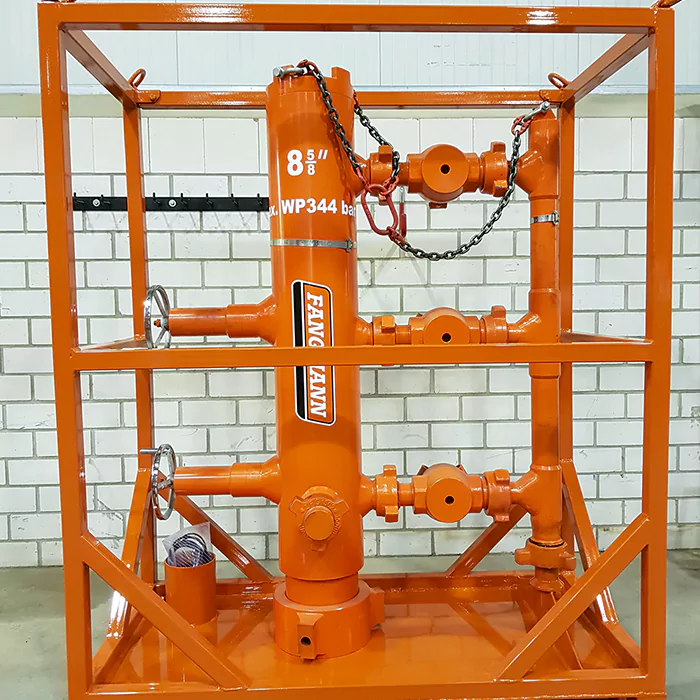

(This picture is our hinged non welded bow spring centralizer under the drift test. What is drift test and why it is important? Check this page: Drift Test >> )

- Superior Structural Integrity (No Weld Failure): By eliminating welds, the primary point of failure in standard bow springs is removed. Welds can be inconsistent and prone to cracking under high impact or cyclic loading (like reciprocating the pipe). The non-welded design ensures the full strength of the parent material is maintained.

- Increased Restorative Force and Resilience: The mechanical joining process is often more consistent, allowing the spring material to retain its original mechanical properties. This results in a higher, more consistent restorative force (the ability to push the casing back to the center) according to API Spec 10D standards.

- Ease of Installation: The hinged design allows rapid assembly on the rig floor. This saves valuable rig time because crews don’t need to lift and slide heavy, assembled centralizers over the entire length of the casing joint.

Hinged Non-Welded Bow Spring Centralizer suitable for

The Single Piece Centralizer is the assurance policy for the most demanding well construction projects. We recommend this premium solution for:

Extended Reach & Horizontal Wells: Where lateral friction and gravity severely challenge casing standoff.

Deepwater and Ultra-Deep Wells: Where high combined axial and compression loads require tools with zero structural weaknesses (API 8C standards support this reliability).

High-Pressure, High-Temperature (HPHT) Wells: Where the tools must maintain performance under intense thermal and mechanical stress.

Wells Utilizing Rotating Cementing: Its superior rigidity and construction are optimized to work seamlessly with the rotation capabilities of a Top Drive Cementing Head (TDCH), maximizing mud displacement.

data sheet of Hinged Non-Welded Bow Spring Centralizer

| Size (in) |

ID | OD (mm) |

ID (mm) |

Length (mm) |

Part No. |

|---|---|---|---|---|---|

| 4 | 5 | 130 | 105 | 300 | HW04120600 |

| 4-1/2 | 5-3/4 | 149 | 118 | 300 | HW04120600 |

| 4-1/2 | 6 | 149 | 118 | 300 | HW04120600 |

| 5 | 6 | 156 | 131 | 300 | HW05000778 |

| 5-1/2 | 8-1/2 | 215 | 143 | 305 | HW05120812 |

| 7 | 8-1/4 | 215 | 183 | 350 | HW07000814 |

| 8-1/2 | 220 | 183 | 350 | HW07000812 | |

| 8-3/4 | 225 | 183 | 350 | HW07000834 | |

| 9-7/8 | 255 | 183 | 350 | HW07000978 | |

| 7-5/8 | 9-7/8 | 255 | 196 | 365 | HW07580978 |

| 8-5/8 | 11 | 282 | 223 | 350 | HW08581100 |

| 12-1/4 | 318 | 223 | 350 | HW08581214 | |

| 9-5/8 | 11 | 285 | 248 | 400 | HW09581100 |

| 11-5/8 | 302 | 248 | 400 | HW09581158 | |

| 11-3/4 | 305 | 248 | 400 | HW09581134 | |

| 12-1/4 | 318 | 248 | 400 | HW09581214 | |

| 10-3/4 | 12-1/2 | 320 | 248 | 400 | HW09581212 |

| 13-1/2 | 350 | 278 | 444 | HW10341214 | |

| 14-3/4 | 375 | 278 | 444 | HW10341312 | |

| 11-3/4 | 14-3/4 | 375 | 303 | 450 | HW10341434 |

| 13-3/8 | 15-1/2 | 395 | 303 | 450 | HW11341412 |

Get Quotation

Hinged Non Welded Bow Spring Centralizer

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

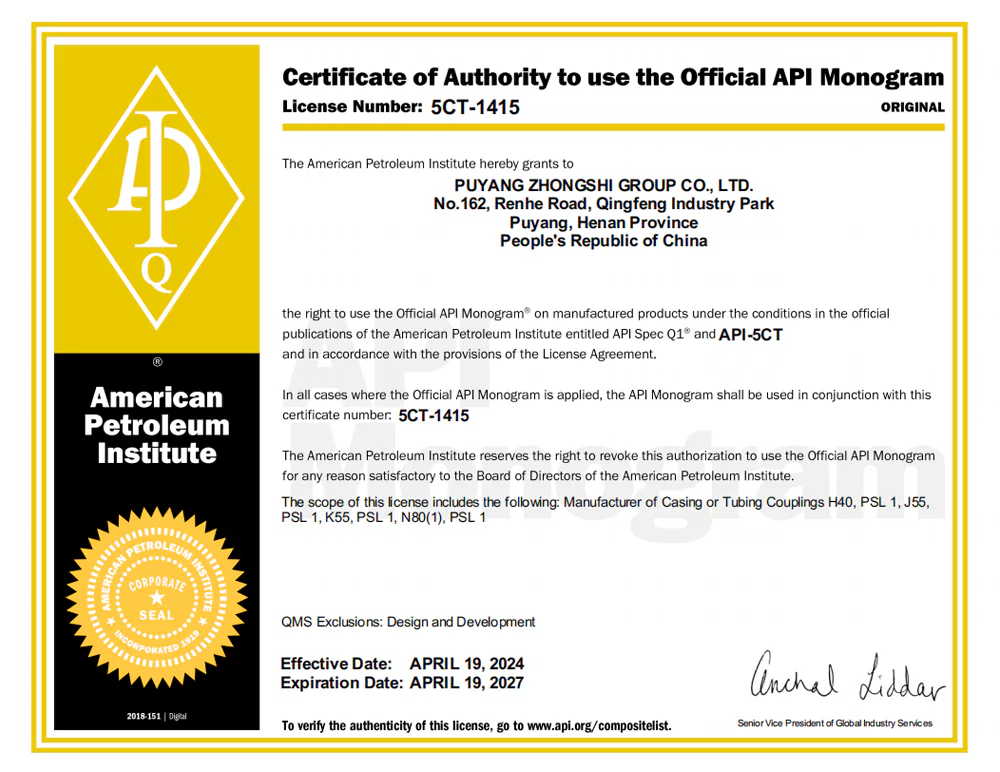

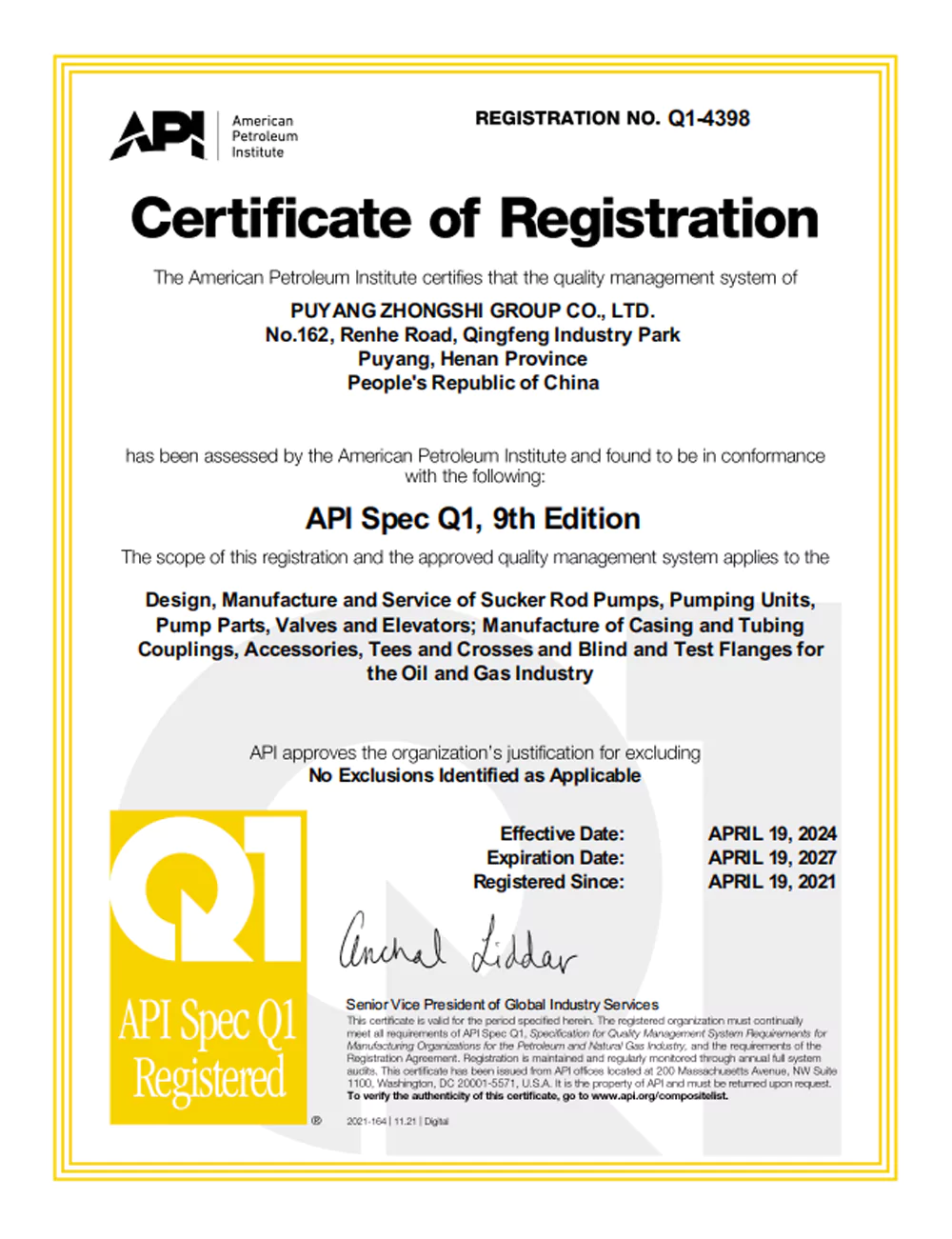

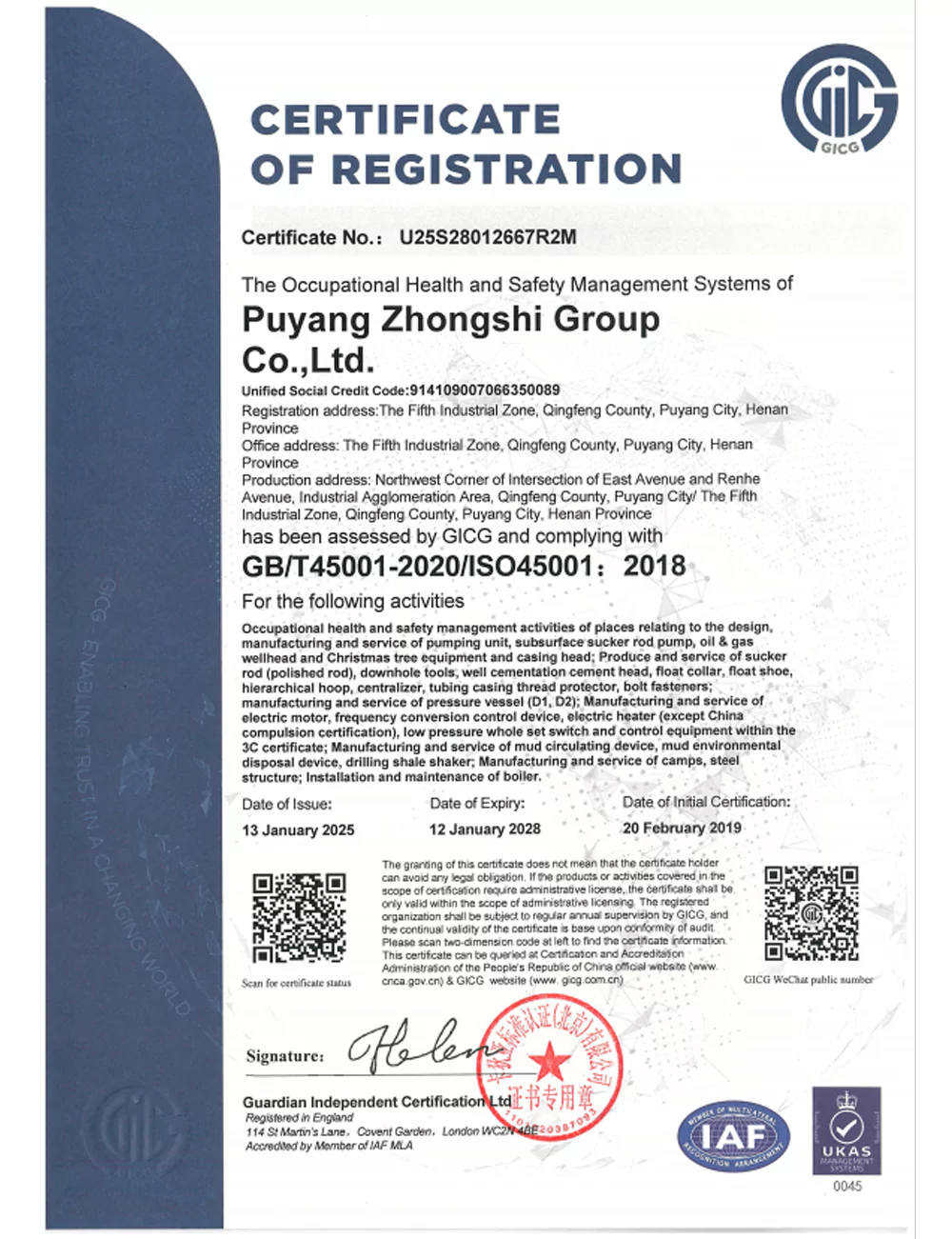

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.