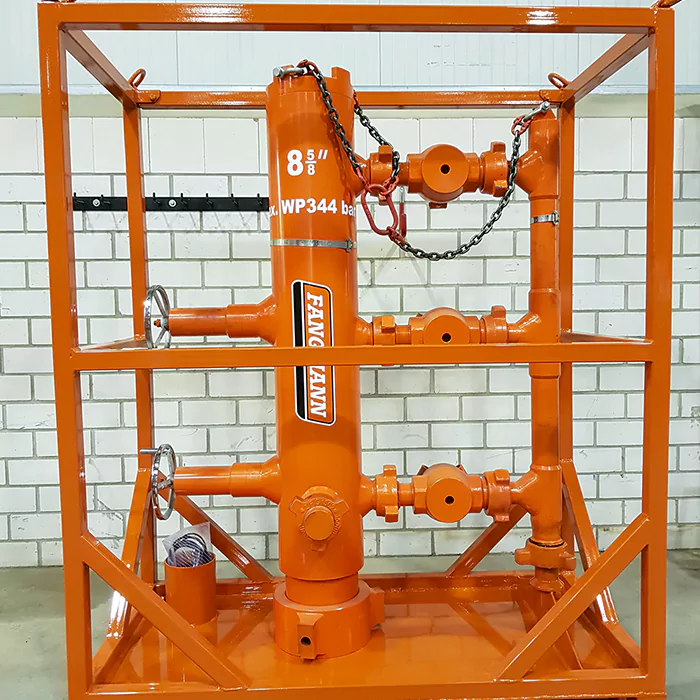

Latest Milled Reamer Shoe Casing

Our new type milled reamer shoe is an engineering leap forward. We’ve replaced the traditional welding process with advanced, one-piece CNC milling. This means you get a superior tool at the same price, delivering unmatched reliability and efficiency on every run.

Puyang zhongshi group co ltd is the API certified China supplier of reamer shoe. We export over 40 countries and regions, including key oil-producing nations in Russia, the Middle East, Central Asia, and Africa. Choose us to be your reliable partner!

New Milled Reamer Shoe casing

A Reamer Shoe can effectively handle expected or sudden problems during the running-in of casing and liners, providing reliable protection.

It is specially designed for complex wellbore conditions and can deal with situations such as swelling shale, ledges, and wellbore washouts.

Various API standard and special thread connections are available upon request, with sizes ranging from 4-1/2 inches to 20 inches.

How does a reamer shoe working?

A reamer shoe is designed with cutting structures or blades on its outer surface, which are typically made of tungsten carbide or other hard, durable materials. As the casing string is lowered, these blades rotate with the casing and ream out any tight spots, cuttings beds, or bridges that could prevent the casing from going all the way to the bottom.

This differs from a standard guide shoe, which simply helps the casing slide past obstructions. The reamer shoe actively “drills” or “reams” through them, ensuring a clean and unobstructed path.

advantages of a reamer shoe

Overcoming Obstructions: Its primary advantage is its ability to handle difficult wellbore conditions. In deviated or horizontal wells, or in formations that are prone to sloughing (collapsing), a reamer shoe is often the only way to get the casing to the bottom of the well.

Time-Saving: It eliminates the need for a separate trip to run a reaming bit, which saves significant rig time and costs.

Improved Cementing: By ensuring the casing is fully on the bottom and the hole is clean, it facilitates a more effective cementing job. A well-placed casing string is essential for a proper cement seal around the outside of the pipe.

Ream Shoe: Traditional Welted V.S. new Type Milled

| New Milled Reamer Shoe (CNC) | Old Welded Reamer Shoe | |

|---|---|---|

| Manufacturing Process | One-piece milling from a single block of steel. | Multiple pieces welded together. |

| Structural Integrity | Superior. No stress points or brittle areas from welding. | Lower. Welding can create weak spots and residual stress in the metal. |

| Performance | Highly precise cutting geometry. | Less precise, depends on welding quality. |

| Reliability | Extremely high. One-piece design reduces the risk of failure. | Lower. Welded joints can fail under high stress. |

| Overall Value | Exceptional. Same price for a technically superior, more reliable product. | Good, but limited. The value is capped by the limitations of the manufacturing process. |

Why the New type milled reamer shoe is Better than the traditional welded?

- Seamless, uniform body eliminates weak points. Retains the original strength and integrity of the steel.

- Higher durability to withstand extreme downhole pressure and torque without fracturing.

- More aggressive and consistent reaming. Efficiently clears obstructions and cleans the wellbore.

- Reduces operational risk and costly downtime caused by tool failure.

- Higher ROI for your operation. You get a premium tool without the premium price tag.

data sheet of reamer shoe casing

| Size (mm) / (in) |

OD (mm) |

ID (mm) |

Reamer OD (mm) |

Length (mm) |

Nozzle ID (mm) |

Thread Type | Part No. |

|---|---|---|---|---|---|---|---|

| 140 5-1/2 |

160 | 127.3-118.6 | 550 | 45 | API / Premium | GSBCCT140 | |

| 168 6-5/8 |

187.8 | 153.6-144.1 | 600 | 45 | API / Premium | GSBCCT168 | |

| 178 7 |

200 | 166-150.4 | 600 | 45 | API / Premium | GSBCCT178 | |

| 194 7-5/8 |

219.1 | 178.4-162 | 600 | 45 | API / Premium | GSBCCT194 | |

| 219 8-5/8 |

244.5 | 205.6-190.8 | 600 | 45 | API / Premium | GSBCCT219 | |

| 244 9-5/8 |

269.7 | 226.6-214.3 | As Needed | 650 | 70 | API / Premium | GSBCCT244 |

| 273 10-3/4 |

298 | 258.9-242.8 | 650 | 70 | API / Premium | GSBCCT273 | |

| 298 11-3/4 |

323.9 | 281.5-273.6 | 650 | 70 | API / Premium | GSBCCT298 | |

| 324 12-3/4 |

350.7 | 296-314.5 | 700 | 70 | API / Premium | GSBCCT324 | |

| 340 13-3/8 |

365 | 320.4-313.6 | 700 | 70 | API / Premium | GSBCCT340 | |

| 406 16 |

431.8 | 384.1-381.3 | 700 | 70 | API / Premium | GSBCCT406 | |

| 473 18-5/8 |

508 | 450.9 | 750 | 70 | API / Premium | GSBCCT473 | |

| 508 20 |

531 | 485.7-475.7 | 750 | 70 | API / Premium | GSBCCT508 |

Get Quotation

Latest Milled Reamer Shoe Casing

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

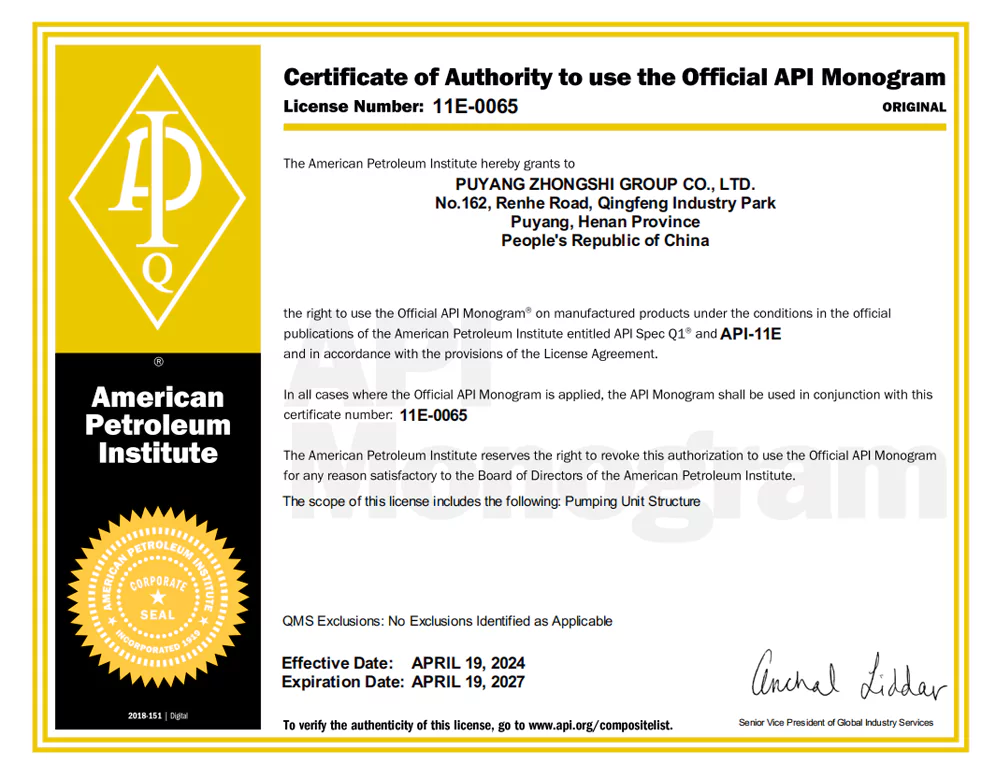

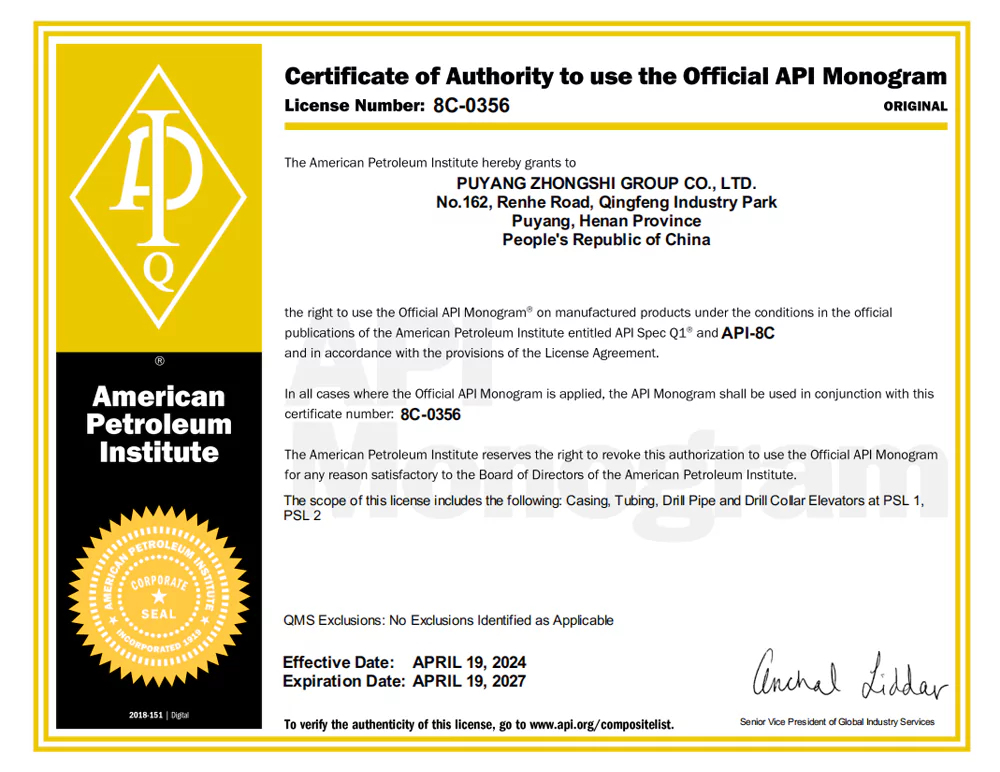

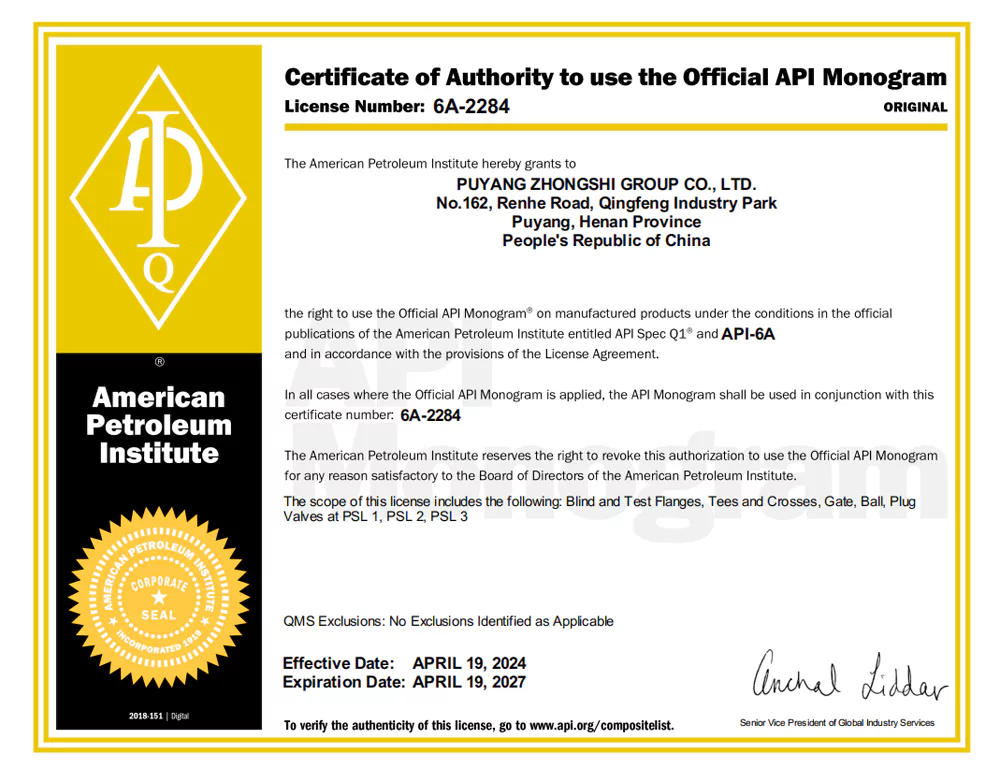

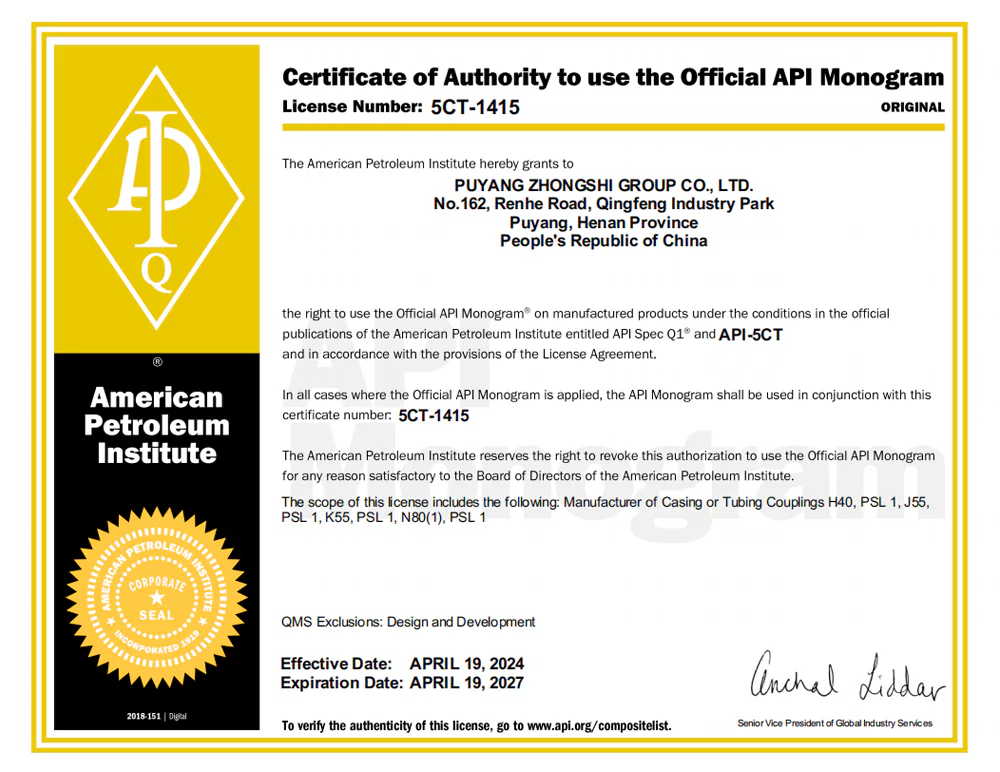

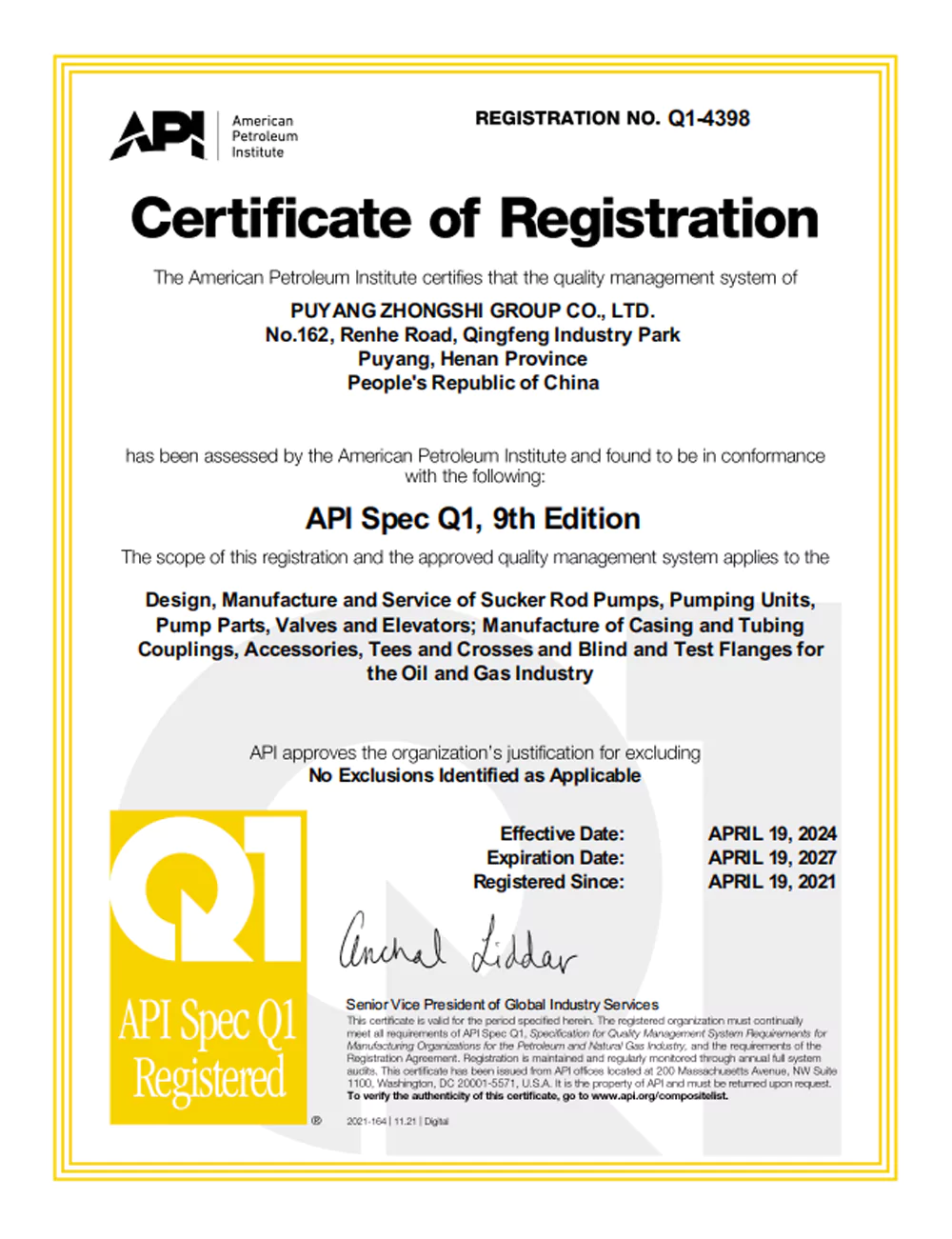

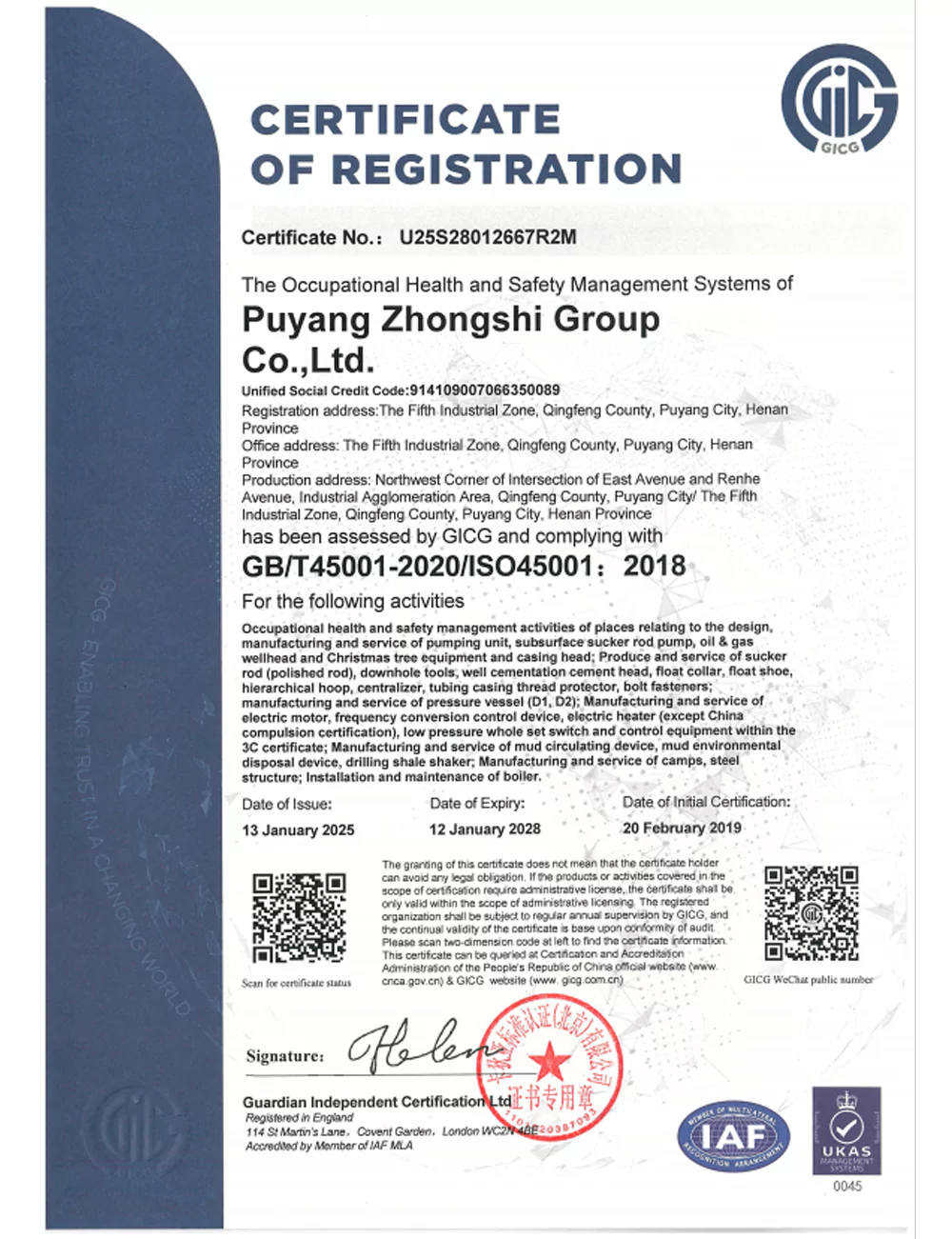

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.