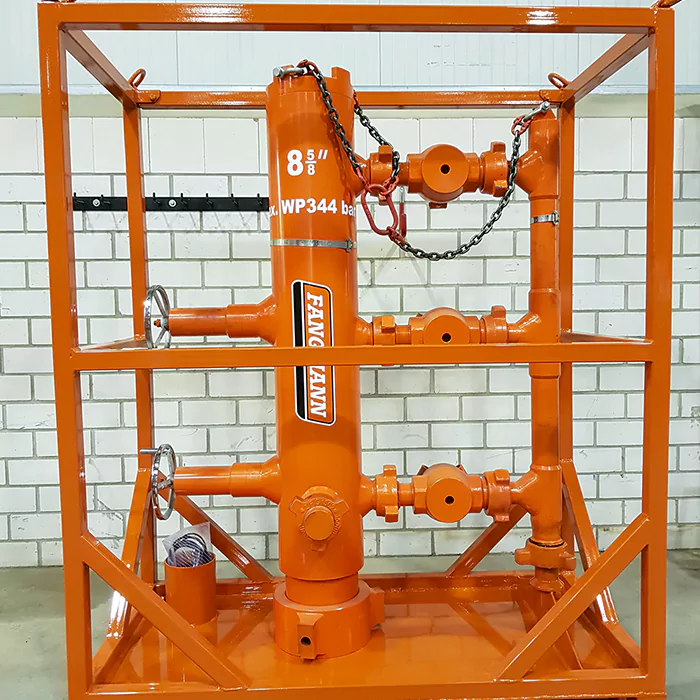

Stab In Float Collar Casing

A stab-in float collar casing is a specialized type of float collar used in oilfield well cementing operations. It allows a smaller-diameter string of drill pipe to be stabbed into it, enabling cementing to be performed through the inner drill pipe rather than the larger casing string. PYZS is the API certified manufacturer and supplier for all types of cementing tools including the float collar. Contact us to get more details now!

What are Stab-in Float Collar Casing?

Stab-in float collar casing is specialized casing accessories used for cementing large-diameter casing strings. Their key feature is a receptacle that allows a smaller-diameter drill pipe to be “stabbed in” directly, creating a fluid path for the cement slurry.

This method, known as inner string cementing, is a significant improvement over conventional cementing for large casings.

Features of Stab-in Float Collar casing

- The valve is made of drillable material, the body is made of phenolic resin, and the spring is made of tin bronze. Overall performance meets API RP 10F IIIC requirements.

- For internal cement filling, high sulfur-resistant oil well cement is selected, which has good drillability and good erosion resistance.Thread processing inspection is performed in accordance with API 5B standards.

- It is suitable for one-time squeeze cementing of large-sized surface casing and technical casing, and can bear the weight of 30 tons of drilling tools.

How They Work

With a stab-in system, the cement is pumped down the drill pipe and out through the float shoe or collar. This method offers several advantages:

- Reduced Cement Volume: It eliminates the need to fill the entire large-diameter casing with cement, which is required in conventional cementing. This saves a significant amount of cement and reduces costs.

- Improved Accuracy: Pumping cement through the smaller drill pipe allows for better control and accuracy in placement. The cement is less likely to become contaminated by drilling mud.

- Faster Operations: It reduces the time required for circulating, pumping, and drilling out excess cement, leading to less rig time.

- Lower Pressures: Cementing pressure is confined to the drill pipe, which protects the larger, more expensive casing from high pressures.

Both stab-in float collars and float shoes are available in single and double valve configurations to provide a fail-safe backflow prevention mechanism.

data sheet of stab in float collar casing

| Size (mm) / (in) |

OD (mm) |

ID (mm) |

Length (mm) |

Nozzle ID (mm) |

Thread Type | Pressure (Mpa) |

Weight (KG) |

Part No. |

|---|---|---|---|---|---|---|---|---|

| 140 5-1/2 |

160 | 127.3-118.6 | 550 | 45 | API / Premium Thread | 35 | 38 | FCBCCTIN140 |

| 168 6-5/8 |

187.8 | 153.6-144.1 | 550 | 45 | API / Premium Thread | 35 | 42 | FCBCCTIN168 |

| 178 7 |

200 | 166-150.4 | 550 | 45 | API / Premium Thread | 35 | 56 | FCBCCTIN178 |

| 194 7-5/8 |

219.1 | 178.4-162 | 550 | 45 | API / Premium Thread | 35 | 64 | FCBCCTIN194 |

| 219 8-5/8 |

244.5 | 205.6-190.8 | 550 | 45 | API / Premium Thread | 35 | 72 | FCBCCTIN219 |

| 244 9-5/8 |

269.7 | 226.6-214.3 | 550 | 70 | API / Premium Thread | 35 | 78 | FCBCCTIN244 |

| 273 10-3/4 |

298 | 258.9-242.8 | 550 | 70 | API / Premium Thread | 35 | 98 | FCBCCTIN273 |

| 298 11-3/4 |

323.9 | 281.5-273.6 | 600 | 70 | API / Premium Thread | 35 | 120 | FCBCCTIN298 |

| 340 13-3/8 |

365 | 320.4-313.6 | 600 | 70 | API / Premium Thread | 35 | 148 | FCBCCTIN340 |

| 406 16 |

431.8 | 384.1-381.3 | 650 | 70 | API / Premium Thread | 21 | 182 | FCBCCTIN406 |

| 473 18-5/8 |

508 | 450.9 | 650 | 70 | API / Premium Thread | 21 | 230 | FCBCCTIN473 |

| 508 20 |

531.2 | 485.7-475.7 | 650 | 70 | API / Premium Thread | 21 | 312 | FCBCCTIN508 |

Get Quotation

Stab In Float Collar Casing

why choose puyang zhongshi co ltd?

Premier Authority and Most Capable Supplier in Oilfield

Established in 1996 through the SINOPEC Central Plains Oilfield restructure, Puyang Zhongshi Group Co Ltd operates with a registered capital of 130 million RMB and an annual output of 200 million RMB. We employ over 580 staff, including 160+ technical experts.

Our main product is Oil Machinery, supported by over 10 specialized companies (including cementing tools, pumping units, and wellhead systems) and five international trade departments. For cementing tools, we have a robust monthly capacity of 500 sets of float equipment and 30,000 centralizers.

We have built long-term strategic partnerships across major global markets, including USA, Russia, Kazakhstan, Sudan, Indonesia, Iran, and Venezuela.

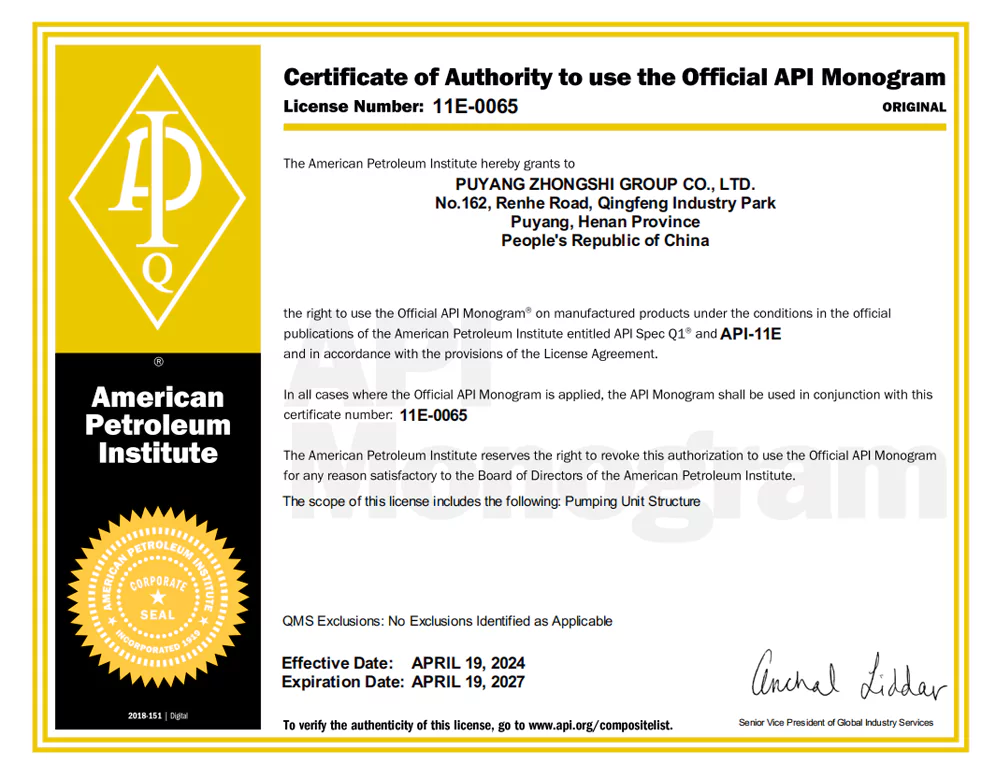

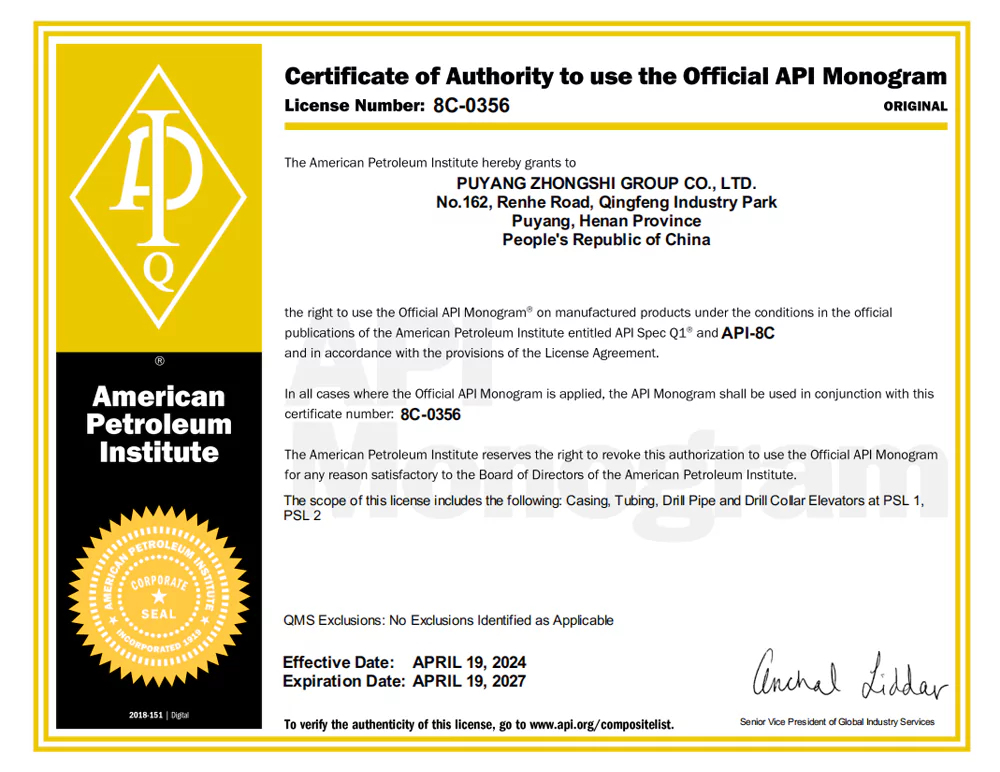

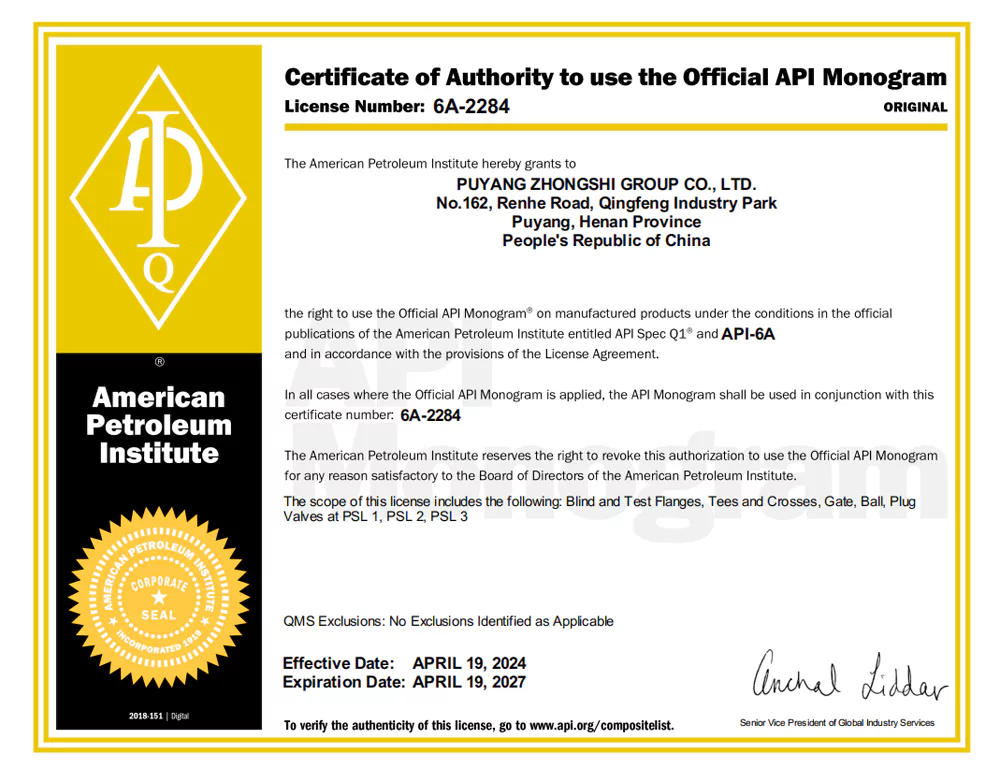

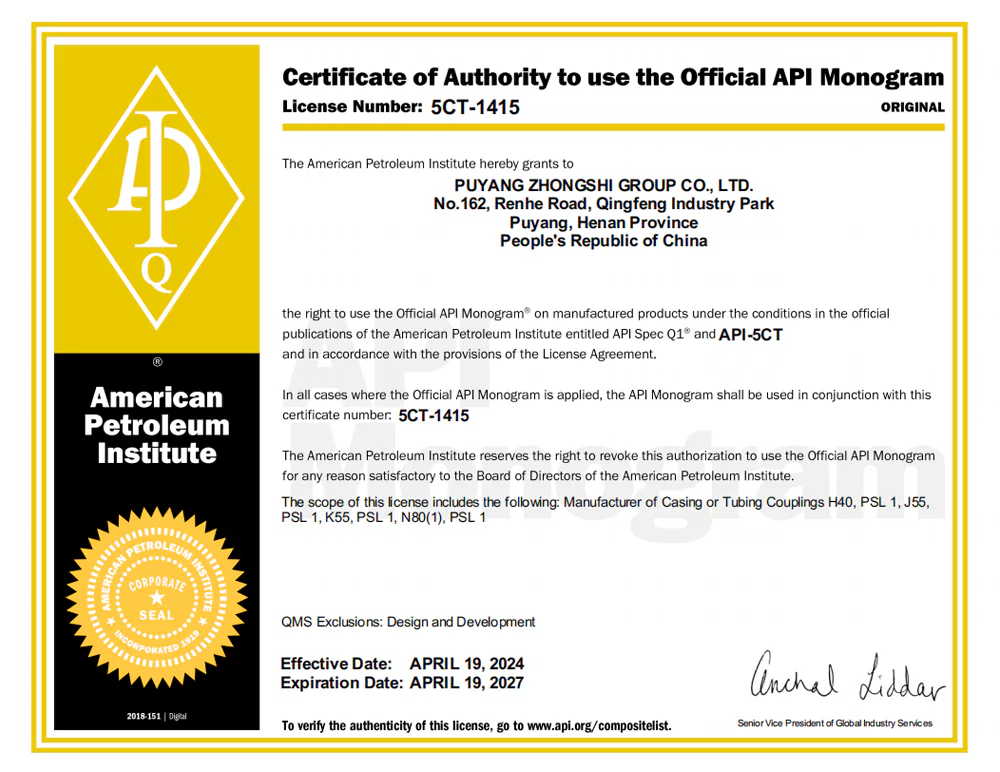

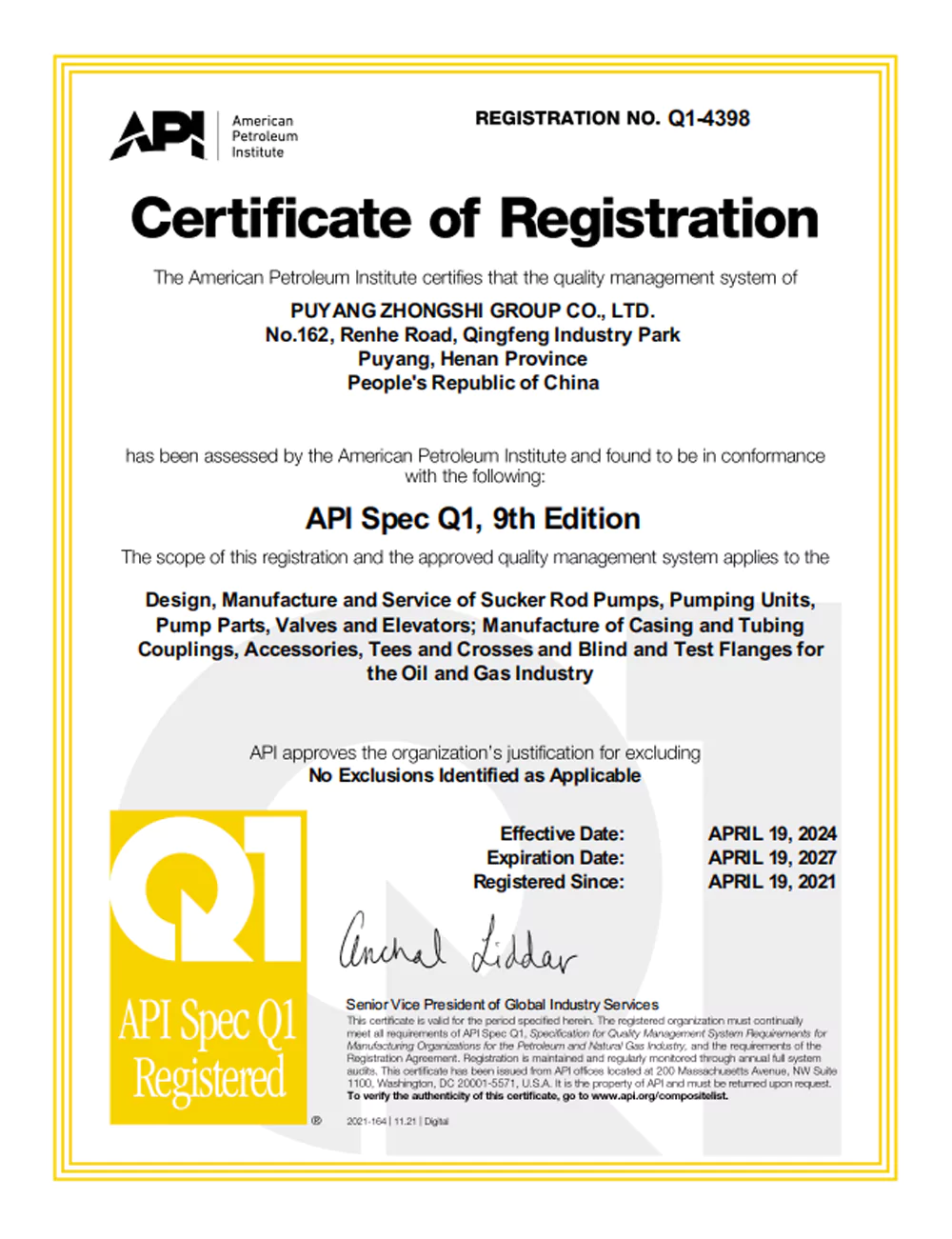

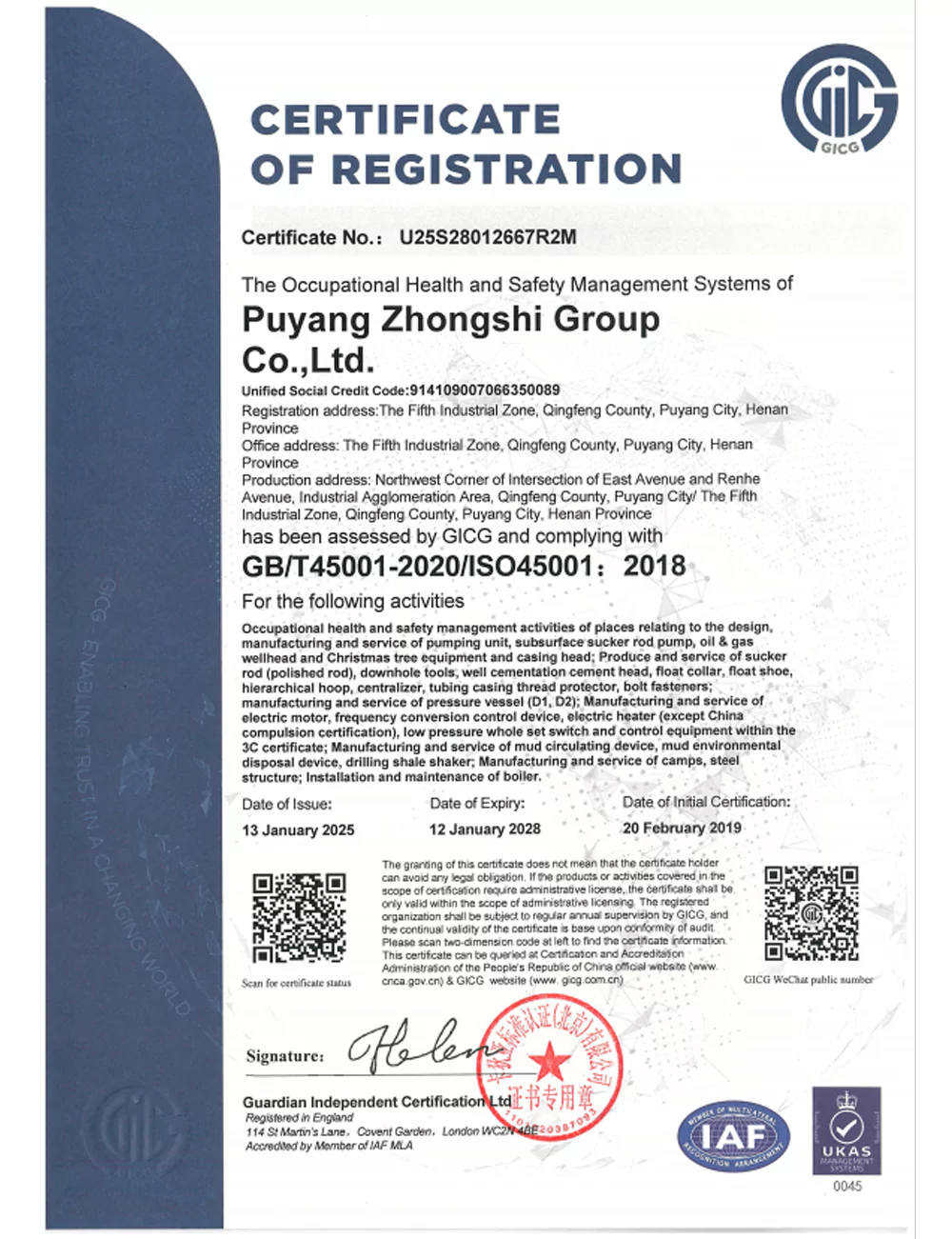

fully certified by API & ISO

The API (American Petroleum Institute) certifications our company Puyang Zhongshi Group holds are excellent and position us very strongly in the global oil and gas market. They provide an authoritative, third-party validation of our product quality and system reliability.

Having the API Q1 certification immediately places our company Puyang zhongshi group co ltd in the top tier of suppliers. Many smaller manufacturers only hold ISO 9001, but the Q1 certification signals a commitment to the oil and gas industry’s most demanding quality requirements, especially relevant for services and complex equipment.

Supplier of the SLB, Halliburton & Baker Hughes

We are the stable supplier of the International Big Three—Schlumberger, Halliburton, and Baker Hughes. Our established partnership with these global leaders means our products and services are proven to meet the industry’s most rigorous standards. Our clients include many top oil service companies in the world.